Pressure Transmitters and Transducers

As a pressure transducer manufacturer, MicroSensor provides a wide range of pressure transmitters and transducers for process control, marine, industrial gases, food and beverage, HVAC and telemetry, etc. The pressure transmitter ranges from 0.1bar to 1000bar, outputs 0.5V~2.5V DC / 0.5V~4.5V DC / 4mA~20mA DC, etc. Some pressure transmitters are certificated with ATEX explosion-proof, Exd as well as UL and are suitable for hazardous environment use. Custom design is available.

MPM489 ATEX pressure transmitter is an ideal solution for automation control applications that require precise measurement. MPM489 can use in harsh environments and hazardous areas.

M20 is highly cost-effective while achieving high reliability. It is suitable for various pressure monitoring and measurements in general industrial occasions.

Digital Pressure Transmitters

Digital pressure transmitters output digital I2C, RS485, MODBUS, and HART signals for applications. MicroSensor offers low power consumption digital pressure transmitters with a 3.3V power supply. The pressure ranges from 0.07bar to 1000bar. Digital pressure transducers with high precision are suitable for tank monitoring, agriculture irrigation, hydropower plant applications, etc.

MPM3801GRF outputs Standard I²C or SPI protocols. It is a digital I2C pressure transmitter for volume correctors, flowmeter which has excellent corrosion resistance and long-term stability.

MPM486 with HART protocol, is available to manage, adjust or monitor the process variables by HART communicator or software, and with local LCD display. It can measure fluid pressure precisely.

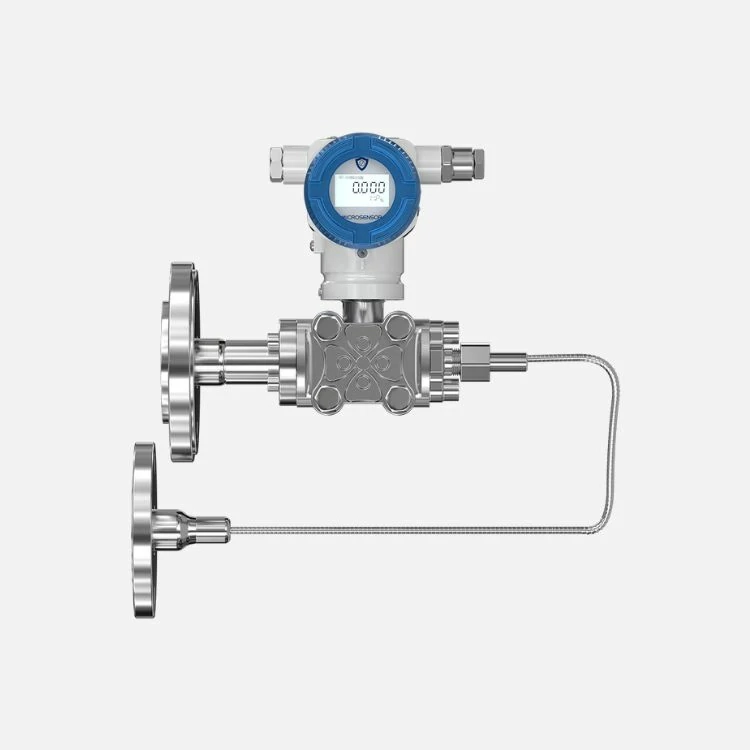

Differential Pressure Transmitters

MicroSensor differential pressure transmitter is for low range pressure measurement for air and gases. The low-pressure range can be 10 mbar, the best accuracy of the differential pressure transmitter can be ±0.075%FS. It can be widely used in the chemical, gas and oil filed.

MicroSensor offers MPM4901FL differential pressure sensor or transmitter for oxygen pressure measurement, specializing in gas pressure measurement in medical oxygen production equipment and oxygen storage tanks.

MDM7000 Series Smart Differential Pressure Transmitter supports remote setting, monitoring and other functions through communication equipment. It is necessary for controlling and optimizing energy use, and maintaining product quality.

Different Types of Pressure Measurement

There are different pressure types of pressure measurement based on the principle of operation: gauge pressure, absolute pressure, and differential pressure.

• Gauge Pressure

It takes the atmospheric pressure as the reference point. Since the atmospheric pressure may vary according to different locations, a gauge pressure sensor is needed to ensure accurate pressure measurement. Generally, a gauge pressure sensor has a vented tube connecting atmosphere pressure as a reference point to measure the media pressure.

• Absolute Pressure

It takes the perfect vacuum as the reference point. Absolute pressure measurement is commonly used in vacuum systems and applications where zero pressure is crucial.

A formula shows the difference between gauge pressure and absolute pressure: Absolute pressure = gauge pressure + atmospheric pressure

• Differential Pressure

The pressure difference between two points or systems is known as differential pressure. A differential pressure transmitter is a specific differential pressure in that one pressure is always atmospheric.

Main Components of Pressure Transmitter and Transducer

The pressure transmitter is also known as a pressure transducer in some areas. It is a device used to measure and transmit a signal proportional to the pressure applied. The structure of a pressure transmitter can vary depending on the application, but typically includes the following main components:

• Sensing Element

This is the essential component for pressure measuring that converts the applied pressure into an electrical signal.

• Circuit Board Chip

Circuit board chips are divided into analog chips and signal conditioning chips. This component amplifies or processes the electrical signal into a transmittable, unified standard signal. It can be a 4-20 mA current loop, voltage output and digital outputs.

• Housing

The sensing element and circuit board chip are enclosed in a housing to protect them from environmental factors like vibration, shock, and moisture. Housing with optional materials such as stainless steel 316L, SS 304, Hastelloy C, Tantalum, etc., according to the different working environments.

• Electrical Connection

These connectors link the transmitter to the power supply and other instrumentation in the control system. B1 4-pin Plug Connector, B2 Cable Connection, and other types are available. The choice of electrical connection depends on factors such as the current carrying capacity, voltage level, application requirements, and industry standards.

• Process Connection

It involves the physical connection between the pressure transmitter and the process piping or equipment. There are several types of process connections commonly used in industrial applications, including thread connection, flanged connection, clamp connection, etc.

The choice of process connection depends on factors such as the process fluid, pressure, temperature, pipe size, and compatibility with the instrument. It is important to select the appropriate process connection to ensure accurate measurement, reliable operation, and safety.

Differences Between Digital and Analog Output of Pressure Transmitters

According to the characteristics of the output signal, the output mode of the pressure transmitter has analog output and digital output.

• Analog Pressure Transmitter

Common pressure sensor analog outputs include 4-20mA, 0-5V/10V DC, 0.5-4.5V DC, etc. In practical applications, users can more conveniently collect, process and restore analog signals.

In maintaining the output signal's consistency, the analog pressure transmitter is more convenient to replace and maintain on-site. Compared with digital output products, the system response speed of analog output products is faster. Therefore, in special working conditions with higher requirements on frequency response, analog output pressure transducers are more suitable.

• Digital Pressure Transmitter

Common digital outputs include RS485, I²C, HART, etc. Its system cost is lower when solving multi-point measurement applications. Compared with analog output products, the digital pressure transmitter is convenient for networking and conducive to online adjustment.

Among many digital products, RS485-Modbus is one of the most widely selected. The product has strong anti-interference ability and long transmission distance. I²C hardware is low-cost, fast, and has high data volume.

MicroSensor provides digital and analog output signal pressure transducers depending on your system compatibility, communication requirements, noise immunity, and the level of accuracy needed for the application.

Common Communication Protocols for Pressure Transmitters

Commonly used pressure transmitter communication protocols include 4-20mA, MODBUS, HART, etc. These communication protocols enable data transmission between the transmitter and equipment and control systems.

• 4-20mA Analog Signal

4-20mA converts pressure signals into current signals for transmission. 4mA represents zero pressure, and 20mA represents full pressure. By measuring the current signal output by the transmitter, the current pressure value can be determined. It is suitable for long-distance transmission, but lacks two-way communication capabilities.

• MODBUS

MODBUS is a serial communication protocol widely used in industrial automation. The pressure transmitter uses the MODBUS protocol to transmit a variety of data, including real-time pressure values, equipment status, alarm information, etc. This protocol has high flexibility and scalability and can be adapted to different control systems.

• HART

HART superimposes digital communication on top of the 4-20mA analog signal. It enables configuration and diagnostic capabilities remotely. The communication protocol is suitable for industrial applications where both analog and digital signals are needed.

Why is Industrial Pressure Measurement Important?

Pressure measurement benefits the following aspects in process industry:

• Safety: Pressure monitoring in industrial environments maintains safe operating conditions. Real-time data and pressure variations also allow for prompt responses to any abnormalities.

• Efficiency: By monitoring pressure, equipment and systems are operating within the specified pressure ranges. This prevents unnecessary strain on machinery to optimize processes for maximum efficiency.

• Quality Control: Consistent pressure levels in manufacturing processes maintain stable production quality, reduce waste and enhance overall efficiency.

• Predictive Maintenance: Pressure transmitters assist in predicting potential equipment failures or issues, facilitating proactive maintenance to prevent costly downtimes.

• Compliance: Many industrial operations are subject to regulations regarding pressure levels. Pressure transmitters help in ensuring compliance with these standards.

Pressure Transmitters & Transducers Application

• Oil & Gas

• Chemical Industry: petroleum, coal mine, Daily chemical industry

• Pulp and Paper

• Electricity

• New Energy: lithium battery, photovoltaic

• Food & Beverage Manufacturing

• Pharmaceuticals

If you are interested in MicroSensor industry solutions, details information can be found on the Solution page.

Resources

-

Meet MicroSensor at Sensor+Test 2025

We are excited to invite you to join MicroSensor at Sensor+Test 2025! Taking place in Nuremberg, Germany, this event serves as a platform for industry professionals to showcase innovations, network, and learn about the latest advanceme...

-

Meet MicroSensor at TAUSENDWASSER 2025

TAUSENDWASSER 2025 emphasizes the importance of conserving and efficiently using water resources. New technologies and products are promoting the water industry. Discover the measurement and control solutions with MicroSensor! Take the...

-

Meet MicroSensor at SMAGUA 2025 with a FREE PASS

At Smagua 2025, you'll have the opportunity to explore MicroSensor measuring products designed to meet the diverse needs of the water and wastewater industry. Our expert team will be on hand to discuss how our solutions can help you en...

-

MDM7100 Pressure Transmitter of Micro Sensor: a Finalist of the Best of Industry Awards 2024

On January 16, 2025 (local time in Würzburg, Germany), the Best of Industry Award 2024 award ceremony came to a successful conclusion! We are honored to announce that Micro Sensor Co., Ltd.(Micro Sensor) has been a finalist for the Be...

-

Micro Sensor Successfully Concludes the 7th Technology Conference

On December 6, the 7th Micro Sensor Technology Conference with the theme of "Preserving Essence, Pursuing Innovation" was successfully held in Xi'an, Shaanxi. More than 200 technical R&D personnel of Micro Sensor participated in the co...

-

Dual Output Pressure Transmitter for Aerial Work Equipment

The dual-output pressure transmitter is mainly used in aerial work platforms, elevating personnel fire trucks, intelligent shelving systems, beam transport vehicles, and beam lifting machines. These applications require high safety sta...

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD