New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

Pressure Transmitters for Process Industry

Smart Differential Pressure Transmitter

MDM7000DP

Range: 20mbar~100bar

Long-term stability: ±0.1% Span/10 years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

Traditional Mounted Gauge/Absolute Pressure Transmitter

MDM7000-DGP/DAP

MDM7000-DAP Accuracy: ±0.1%、±0.2%URL

MDM7000-DGP Range: 60mbar ~400bar

MDM7000-DAP Range: 0.4bar~100bar

Long-term stability: ±0.1% SPAN/10 years

Maximum turndown ratio: 100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

Smart Gauge/Absolute Pressure Transmitter

MDM7000-GP/AP

MDM7000-AP Accuracy:±0.1%, ±0.2%URL

MDM7000-GP Range:0.4bar ~400bar

MDM7000-AP Range:0.1bar~100bar

Long-term stability:±0.1% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

Monosilicon Hygienic Pressure Transmitter

SMP858-TSF-D

Range: 0.1bar~25bar

Output signal: 4~20mA, 4~20mA+HART, Modbus-RTU/RS485 and others

Reference accuracy: ±0.2% upper range limit, maximum ±0.5% upper range limit

Hygienic Pressure Transmitter

SMP858-TSF-S

Range: 0.1bar~30bar

Output signal: 4~20mA, 4~20mA+HART

Reference accuracy: ±0.2% upper range limit, maximum ±0.5% upper range limit

Flange Gauge/Absolute Pressure Transmitter

MDM7000-GP-T/AP-T

MDM7000-AP-T Accuracy:±0.1%、±0.2%URL

MDM7000-GP-T Range:0.4bar~100bar

MDM7000-AP-T Range:0.4bar~10bar

DNV, ABS, KR, NK, and RS approved for installation on vessels

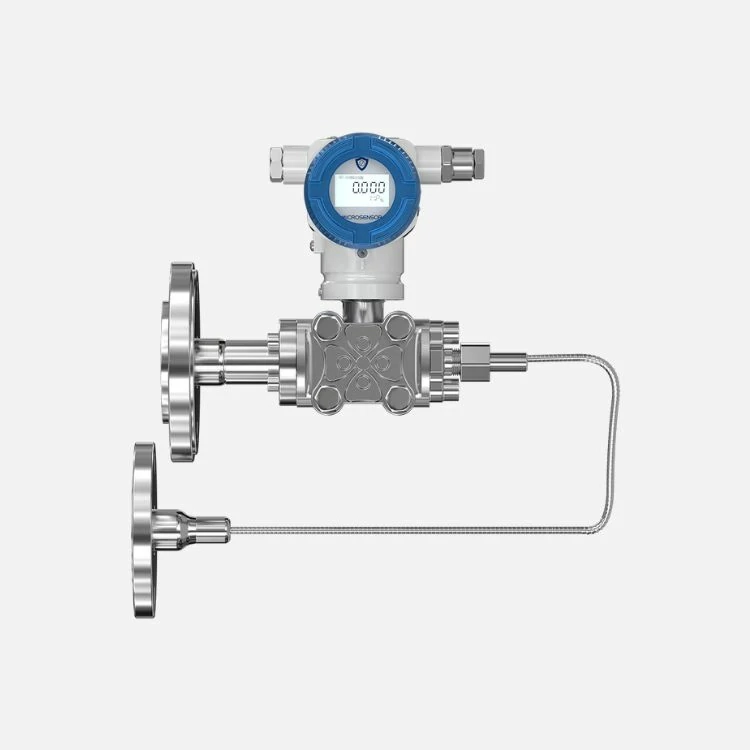

Smart Differential Pressure Transmitter With Remote Diaphragm Seal

MDM7000-LP

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

Smart Level Transmitter

MDM7000LT

Range: 0.4bar~2.5bar

Output Signal: 4mA~20mA DC, HART

DNV, ABS, KR, NK, and RS approved for installation on vessels

What is the Process Industry?

Unlike general manufacturing, the process industry continuously manufactures goods through complicated steps or processes that transform raw materials into finished products. Physical properties change or chemical conversion occurs generally during the processes. The controlled and systematic processes require precise measurements and specific conditions.

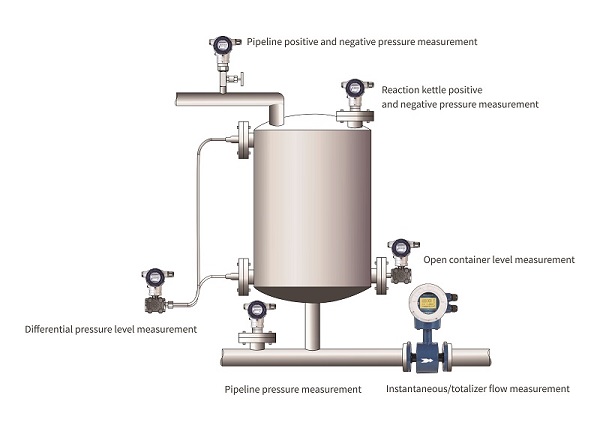

How do Smart Pressure Transmitters Work in the Process Industry?

The production of the process industry is often characterized by flowing materials or media. With precise measurement and control, operations can be optimized in production, quality, energy efficiency, and safety. Check how high precision pressure sensors make sense in different industries as below:

• Chemical

The chemical industry involves various high-temperature, high-pressure, and corrosive media. High-precision measuring of pressure, level, temperature and flow ensures safe production in harsh environments. A complete set of smart control instruments monitors key parameters and optimizes the production process through data integration and analysis. Industrial pressure transmitters with corrosion-resistant materials are also necessary to ensure long-term reliability.

• Paper Making

A lot of pulp and chemicals are produced in the papermaking. They need to be processed and transformed at different steps. Controlling key parameters of production materials increases productivity and reduces energy consumption. Optional configurations of MDM7000 Series can be installed at different locations in towers, pools, tanks, and other containers. The smart pressure transmitters guarantee smooth operation which is used with the control system.

• Food & Pharmaceuticals

From raw materials to the final products, the food and pharmaceutical industries have strict requirements for safety and sanitary. The 3-A and EHEDG certified instruments of Micro Sensor meet stringent industry production standards. Our pressure transmitters are corrosion-resistant and easy to clean, making them suitable for pharmaceutical and food manufacturing environments.

• New Energy

The new energy field adopts smart pressure transmitters to ensure different system control. For example, pressure monitoring ensures standardized transmission of powdered materials in a lithium battery conveying system. Pressure transmitter installation on pipe provides timely feedback on abnormalities.

• Electricity

In power plants and power transmission systems, pressure, level, temperature, and flow parameters directly affect operating efficiency and safety. MDM7000 Series integrates sensor technology and intelligent control systems to achieve precise measurement and control in complex environments.

Video of Smart Pressure Transmitters for Process Industry

| Features of MDM7000 Series |

| Optional Configurations of Smart Pressure Transmitters for Different Process Industry |

Why Choose MDM7000 Smart Pressure Transmitters?

• High Accuracy: Reference accuracy of up to ±0.05%. This high-precision pressure transmitter ensures precise and reliable measurements under various operating conditions.

• Eminent Stability: The product specifications highlight a ten-year installed stability of ±0.1% SPAN. The feature signifies the ability to maintain consistent performance and accuracy over an extended period.

• Strong Environmental Tolerance: Optional various configurations, functional modules, and materials for harsh environments such as corrosion and high-temperature conditions, etc.

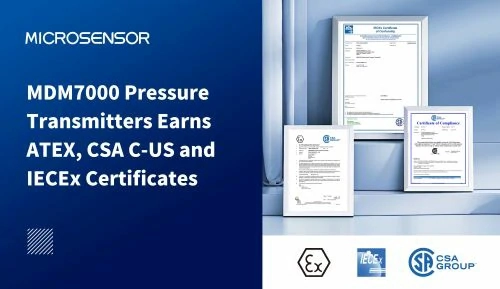

• Complete International Certification: The below authoritative certificates confirm to consumers and businesses the safety and reliability of the utilization.

MDM7000 Series smart DP pressure transmitter provides efficient and reliable differential, gauge, and absolute pressure measurement solutions for automated control and management. They are widely used in industrial fields such as oil and gas, chemicals, lithium batteries, power generation, pulp and papermaking, metallurgy, shipbuilding, food, and pharmaceuticals.

Our team is dedicated to helping you with the right guidance and support for a successful implementation of MDM7000 smart transmitter products in complex operating conditions. If you want more details or assistance with the selection for your specific requirements, please reach out to our experts via our online chat or by email at sales@microsensor.cn.

-

MDM7000 Pressure Transmitters Clear EAC-COC Certificate

MICROSENSOR MDM7000 Smart Pressure Transmitters have successfully obtained the Russian EAC-COC (Eurasian Conformity Certificate of Conformity) certification, paving the way for its sales in the Eurasian Economic Union (EAEU) countries....

-

MICROSENSOR Pressure Transmitters Boost Global Marine Market with DNV Certificate

Recently, a series of transmitters of MICROSENSOR, including models MDM7000, MPM489, MPM489W, MPM4700, MPM426W and MPM4730, have successfully passed the DNV certificates (Det Norske Veritas). Obtaining DNV certificate not only lays a s...

-

MDM7000 Pressure Transmitters Earns ATEX, CSA C-US and IECEx Certificates

Recently, MICROSENSOR's developed and manufactured MDM7000 series smart pressure transmitters have successfully obtained the three major international explosion-proof certifications, namely the ATEX by the CSA Group, the CSA C-US, and ...

-

MDM7000 Pressure Transmitters Received ABS Certificate

Recently, MICROSENSOR's MDM7000 Pressure Transmitters, MPM489 Pressure Transmitter, MPM426W Level Transmitter, MTM4831 Temperature Transmitter, and MFC608 flowmeter have successfully obtained certification from the American Bureau of S...

-

Monitoring Solutions in the Paper Industry

Industry Background The modern papermaking industry is a capital, technology, and energy-intensive sector characterized by large-scale production, high production continuity, complex process flow, high energy consumption, large raw m...

-

Application of MDM7000 Smart Pressure Transmitter in the Maritime Industry

Industry BackgroundShipping is the primary mode of global trade, accounting for over 80% of the world's trade volume, with approximately 95% of China's international trade goods being transported by shipping. As international trade con...

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD