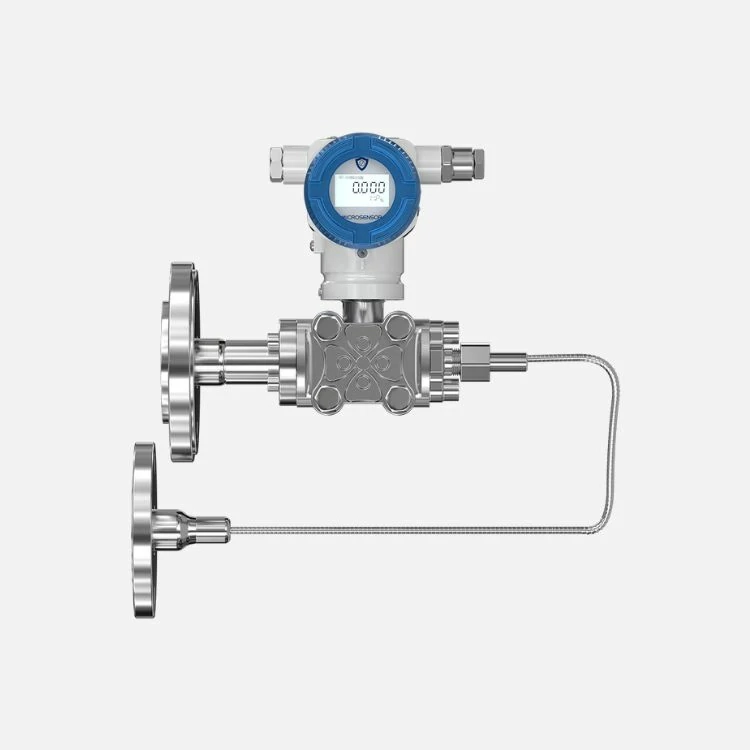

Smart Differential Pressure Transmitter With Remote Diaphragm Seal

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MDM7000LT

Used For

Oil and Gas Industry, Power Generation and Mining Industry, Urban Water Supply and Drainage

Leave a MessageMDM7000-LT Intelligent Level Transmitter is applicable for level measurement of high viscosity, corrosive, and easily precipitated fluids. It supports multiple options of liquid as a filled oil that transmits the media pressure from the flange end to the instrument body. MDM7000-LT can be directly mounted on the flanges available for different standards. The level transmitter has a measuring range of 0.4 bar to 2.5 bar. This transmitter is suitable for use in various industries where precise level measurement is required.

Features

• Measurement Range: 0.4bar~2.5bar

• Support 4~20mA DC, RS485 Modbus signal output

• Available for remote setting and monitoring

• High accuracy with stable performance

• High overload protection diaphragm & EMC protection circuit module

• Monocrystalline silicon piezoresistive sensor technology

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Image:

MDM7000-LT Intelligent Level Transmitter is applicable for level measurement of high viscosity, corrosive, and easily precipitated fluids. It supports multiple options of liquid as a filled oil that transmits the media pressure from the flange end to the instrument body. MDM7000-LT can be directly mounted on the flanges available for different standards. The level transmitter has a measuring range of 0.4 bar to 2.5 bar. This transmitter is suitable for use in various industries where precise level measurement is required.

Features

• Measurement Range: 0.4bar~2.5bar

• Support 4~20mA DC, RS485 Modbus signal output

• Available for remote setting and monitoring

• High accuracy with stable performance

• High overload protection diaphragm & EMC protection circuit module

• Monocrystalline silicon piezoresistive sensor technology

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP Accuracy:±0.075%, ±0.1%FS, ±0.2%URL

MDM7000-AP Accuracy:±0.1%, ±0.2%URL

MDM7000-GP Range:0.4bar ~400bar

MDM7000-AP Range:0.1bar~100bar

Long-term stability:±0.1% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP-T Accuracy:±0.1%、±0.2%URL

MDM7000-AP-T Accuracy:±0.1%、±0.2%URL

MDM7000-GP-T Range:0.4bar~100bar

MDM7000-AP-T Range:0.4bar~10bar

DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.05%, ±0.075%URL

Range: 20mbar~100bar

Long-term stability: ±0.1% Span/10 years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

more info...

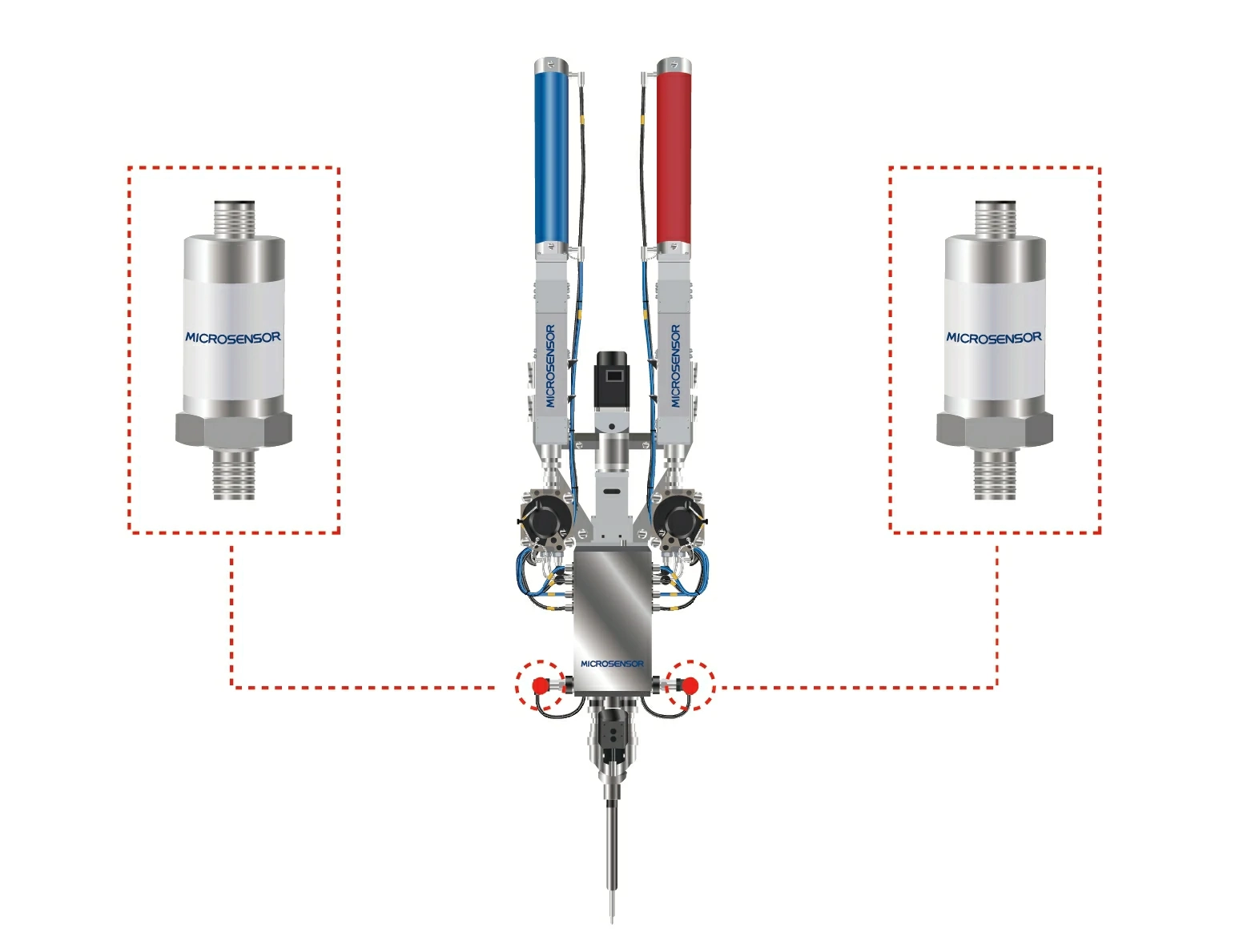

Dispensing machine is used to control adhesive, paint and other liquids. It requires compressed air to be fed into the glue bottle for proper operation. The role of the pressure transmitter is to monitor the pressure at the air inlet to ensure that the dispenser works properly.

more info...

The liquid preparation tank is required to prepare various solvents and basic materials for subsequent production, regardless of whether it is to prepare injections, solutions, or detergents, and it needs to proportion different types of purified water, injection water, sucrose solutions, and suspensions. By measuring the liquid level, the filling and dispensing processes are controlled, and pressure measurement is required for the inlet pipelines of different solutions to prevent tank overflow or empty running through measurement.

more info...

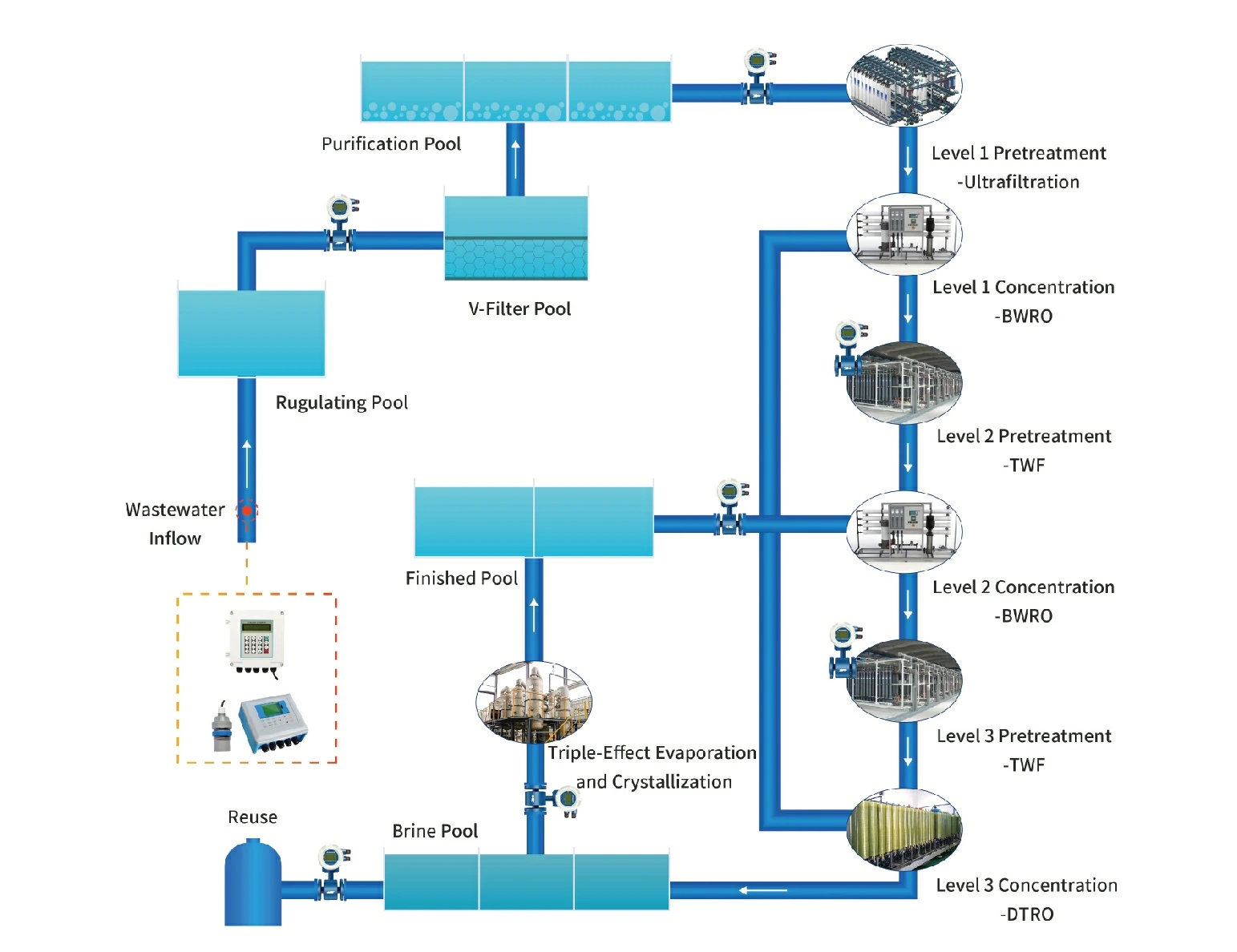

In response to the national sustainable development strategy, enterprises typically install industrial wastewater treatment equipment, such as magnetic flowmeters and open channel flowmeters, to monitor and measure wastewater treatment and discharge.

more info...