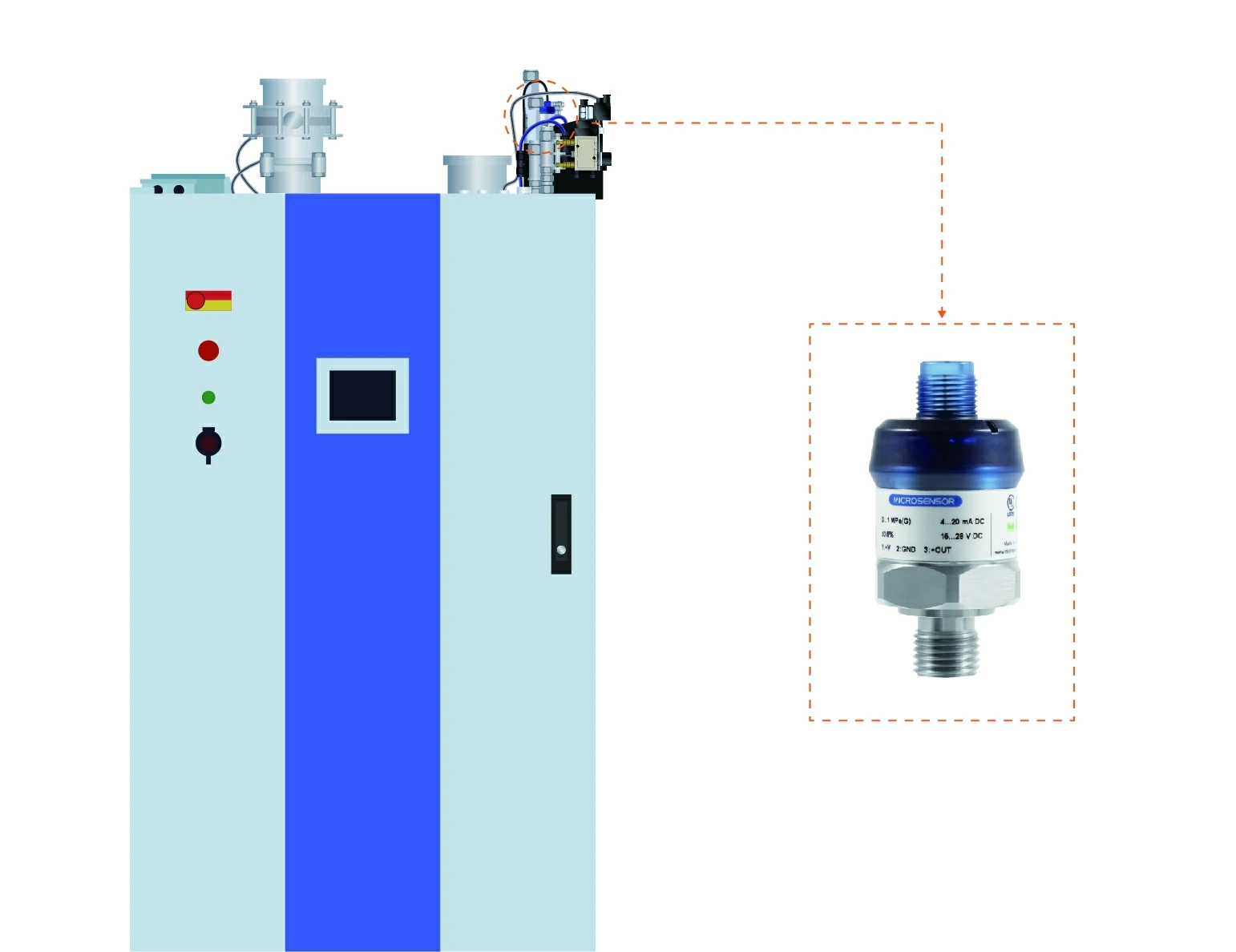

Smart Gauge/Absolute Pressure Transmitter

MDM7000-GP Accuracy:±0.075%, ±0.1%FS, ±0.2% URL

MDM7000-AP Accuracy:±0.1%, ±0.2% URL

MDM7000-GP Range:0.4bar ~400bar

MDM7000-AP Range:0.4bar~100bar

Long-term stability:±0.2% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD