Flow Switch

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MF7000

Used For

Leave a MessageIntroduction

The function of a companion flange is to enable pipeline connections by utilizing pairing to achieve connection and closure.

Sealing gaskets are positioned between the flanges, and fasteners are tightened to ensure reliability and sealing of the connection. Flange connections offer easy assembly and disassembly, facilitating convenient replacements.

When used in pairs, one is designed for instrumentation while the other is welded to the pipeline, mutually referred to as companion-flange. In this order guide, the flange welded to the pipeline is defined as the companion-flange, adhering to standard size specifications.

Function

• Welding neck flange

Applicable to various high-temperature and high-pressure pipeline equipment connections, the primary functions include pipe connection, enhancing safety, adapting to high-temperature and high-pressure conditions, and convenient maintenance.

• Plate flat welding flange

The sealing face is only applicable to RF Raised face (within the recommended range). Its advantages include a simple construction, easy installation, reduced equipment and cost investments, while meeting various pipeline operating conditions.

• Slip-on welding flange

Compared to other pipeline connection methods, its advantages lie in high-pressure resistance, corrosion resistance, excellent sealing, and ease of operation.

• Threaded flange

This is a type of flange that utilizes threading for pipeline connections, eliminating the need for welding. When the flange deforms, it imposes minimal additional torque on the cylinder or pipeline, making it suitable for highpressure pipeline connections.

Image:

Introduction

The function of a companion flange is to enable pipeline connections by utilizing pairing to achieve connection and closure.

Sealing gaskets are positioned between the flanges, and fasteners are tightened to ensure reliability and sealing of the connection. Flange connections offer easy assembly and disassembly, facilitating convenient replacements.

When used in pairs, one is designed for instrumentation while the other is welded to the pipeline, mutually referred to as companion-flange. In this order guide, the flange welded to the pipeline is defined as the companion-flange, adhering to standard size specifications.

Function

• Welding neck flange

Applicable to various high-temperature and high-pressure pipeline equipment connections, the primary functions include pipe connection, enhancing safety, adapting to high-temperature and high-pressure conditions, and convenient maintenance.

• Plate flat welding flange

The sealing face is only applicable to RF Raised face (within the recommended range). Its advantages include a simple construction, easy installation, reduced equipment and cost investments, while meeting various pipeline operating conditions.

• Slip-on welding flange

Compared to other pipeline connection methods, its advantages lie in high-pressure resistance, corrosion resistance, excellent sealing, and ease of operation.

• Threaded flange

This is a type of flange that utilizes threading for pipeline connections, eliminating the need for welding. When the flange deforms, it imposes minimal additional torque on the cylinder or pipeline, making it suitable for highpressure pipeline connections.

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

3.5, 7, 10, 20, 35, 70, 100, 200mH2O

Accuracy: ±0.1%FS (Typ.)

HART Protocol

DNV approved for ship use

Accuracy:±0.2% URL

Range: 0.4bar~10bar

Output Signal: 4mA~20mA DC+HART

DNV, ABS, KR, NK, and RS approved for installation on vessels

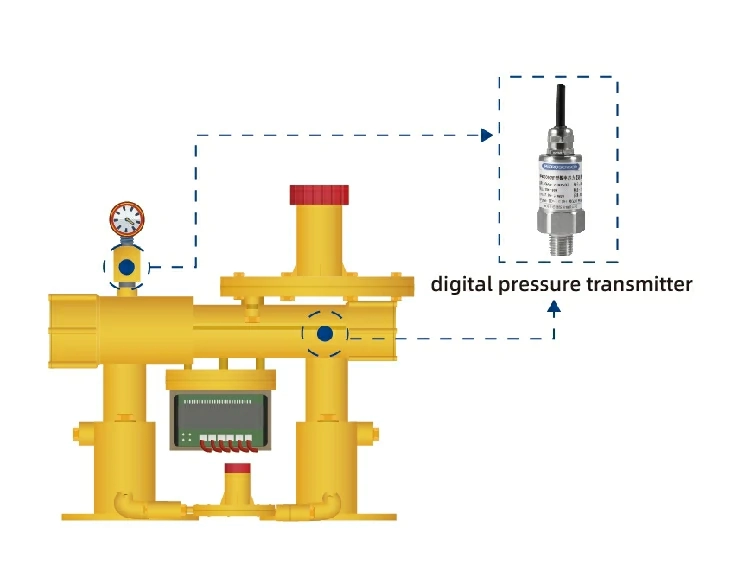

The main function of the gas regulator is to adjust the higher gas inlet pressure to the set lower gas outlet pressure. With a series of changes in gas consumption and inlet pressure, the gas regulator will automatically keep the outlet pressure value within a certain range and play a stabilising role. The pressure transmitter is the core component of the regulator.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...

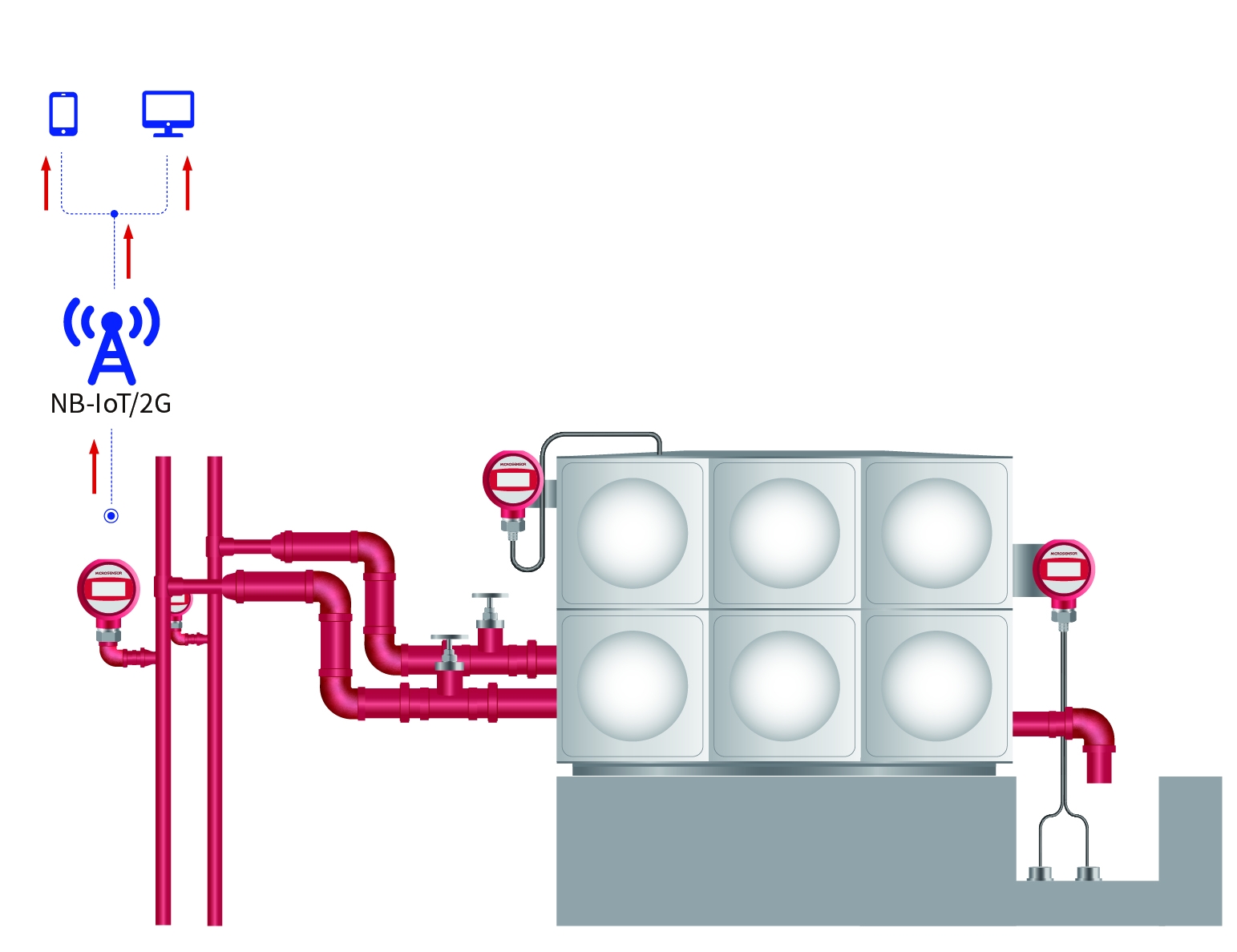

The normal operation of fire-fighting water pipeline plays an important role in safeguarding citizens' personal and property safety. Monitoring instruments are installed at each monitoring point of the fire protection pipeline to monitor pressure and level data in real time, so that when an error occurs, faults are located in time and alarms are given to facilitate staff maintenance and processing.

more info...

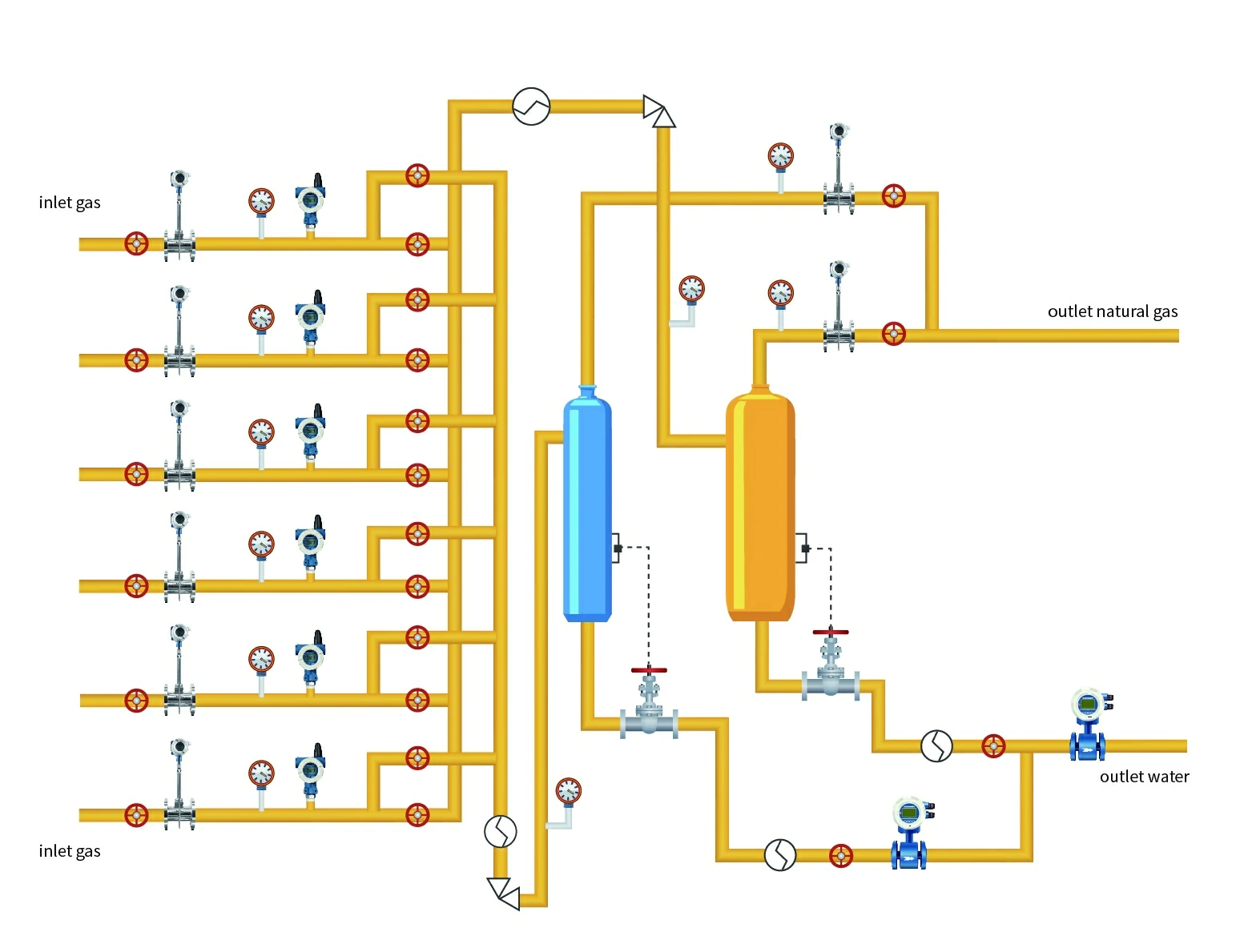

Gas gathering stations gather and process natural gas from multiple wells. Instruments in the pipeline monitor real-time data changes, such as gas or liquid flow. It helps control the water injection for the purpose of measuring and transporting oil and gas.

more info...