Electromagnetic Flowmeter

Diameter: DN6~DN1600

CE, ATEX approved

Flange, sanitary, threaded, clamping type available

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MFM500A

Used For

Power Generation, Metallurgy, Steel, Paper, Boilers

Leave a MessageMFM500A Flow Switch is an intelligent flow monitoring sensor that does not require frequent adjustment and maintenance. It can play an early warning and protection role when there is a traffic failure on key equipment. The switch is based on the principle of thermal diffusion and uses an ARM processing core. Different installation interfaces can be selected to meet various pipe diameter requirements. It is suitable for a variety of application environments, such as real-time monitoring of pipeline water flow, flow monitoring of cooling or lubrication systems. Even in the case of changing temperature, the flow switch of Micro Sensor can guarantee the accuracy of measurement.

Feature

• Self-luminous OLED display

• Optional power supply & mounting interfaces

• Overvoltage, overcurrent, reverse polarity protection

• With temperature compensation and calibration

Specification

• Measure Range: 1cm/s~150cm/s (water);

• Optimal Range: 3cm/s ~ 100cm/s (water)

• Power Supply: (24±4.8)V DC / 220VAC

• Working Current: ≤ 60mA

• Switch Accuracy: ±10cm/s

• Hysteresis: ±2cm/s~±8cm/s

• Initial Time: 2s~15s, 8s(typ.)

• Switch-off Time: 1s~15s, 2s(typ.)

• Switch-on Time: 1s~13s, 2s(typ.)

• Working Temp.: -20℃ ~70℃

Image:

MFM500A Flow Switch is an intelligent flow monitoring sensor that does not require frequent adjustment and maintenance. It can play an early warning and protection role when there is a traffic failure on key equipment. The switch is based on the principle of thermal diffusion and uses an ARM processing core. Different installation interfaces can be selected to meet various pipe diameter requirements. It is suitable for a variety of application environments, such as real-time monitoring of pipeline water flow, flow monitoring of cooling or lubrication systems. Even in the case of changing temperature, the flow switch of Micro Sensor can guarantee the accuracy of measurement.

Feature

• Self-luminous OLED display

• Optional power supply & mounting interfaces

• Overvoltage, overcurrent, reverse polarity protection

• With temperature compensation and calibration

Specification

• Measure Range: 1cm/s~150cm/s (water);

• Optimal Range: 3cm/s ~ 100cm/s (water)

• Power Supply: (24±4.8)V DC / 220VAC

• Working Current: ≤ 60mA

• Switch Accuracy: ±10cm/s

• Hysteresis: ±2cm/s~±8cm/s

• Initial Time: 2s~15s, 8s(typ.)

• Switch-off Time: 1s~15s, 2s(typ.)

• Switch-on Time: 1s~13s, 2s(typ.)

• Working Temp.: -20℃ ~70℃

Diameter: DN6~DN1600

CE, ATEX approved

Flange, sanitary, threaded, clamping type available

Diameter: DN200 ~ DN1600

Accuracy: ±2.5%

Convenient for maintenance and repair

Pressure port: ANSI 1/2 NPT, JIS G1/2

Diameter: DN25 ~ DN400

Structure type: separated type, integrated type

Flange: DN10~DN500

Accuracy: ±0.5%, ±1.0%

Corrosion- and wear-resistant electrode and lining materials available

Corrosion- and wear-resistant materials available

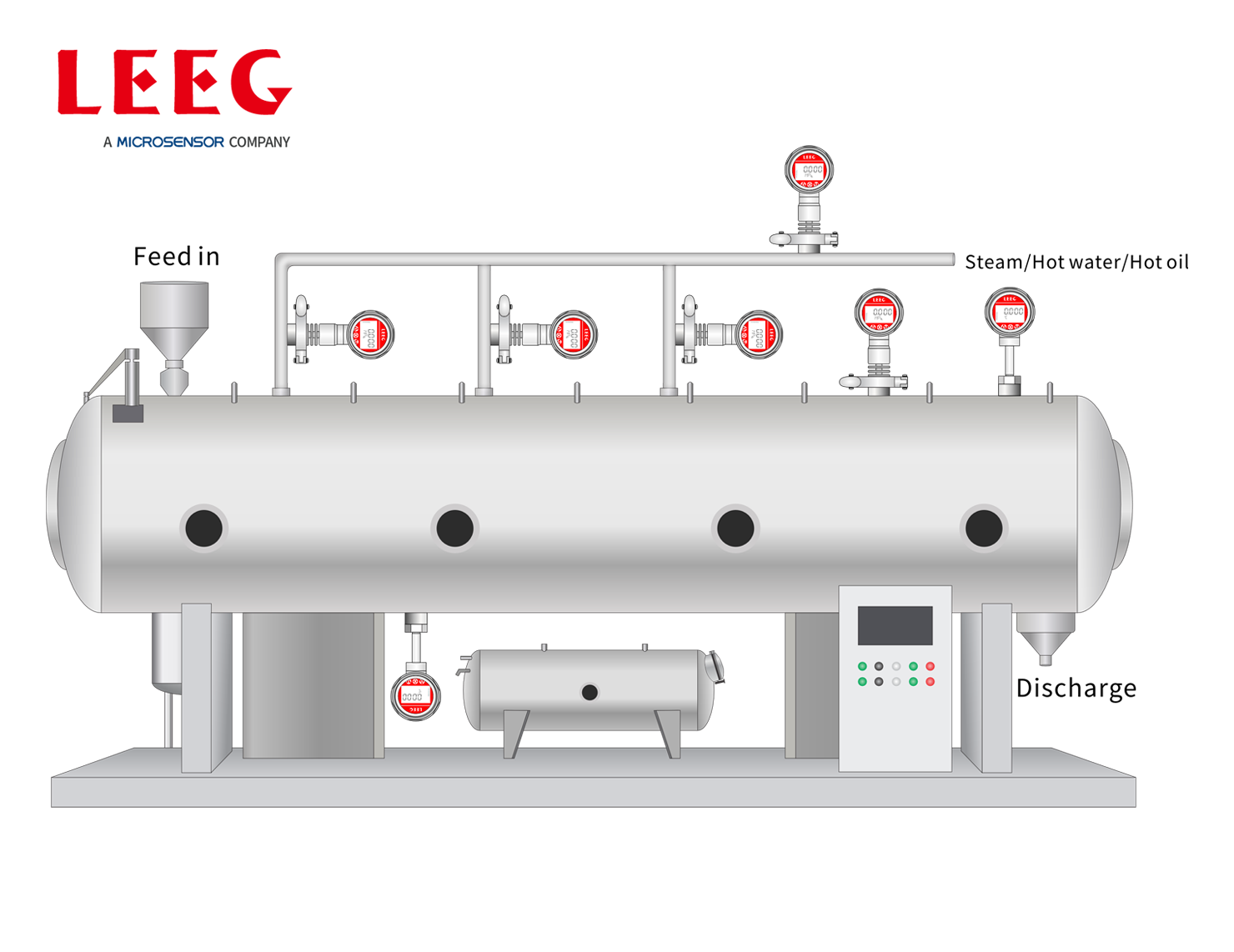

Dryers are often used to dry medicines or extract active ingredients from traditional Chinese medicines, which are easily decomposed in high temperature environments. Temperature measurement is required in the heating area, cooling area and material outlet of the dryer, and pressure transmitters are used to measure the pressure of air or gas to help adjust the air flow speed and fan operation status, or measure the pressure of steam, hot water, and hot oil pipelines.

more info...

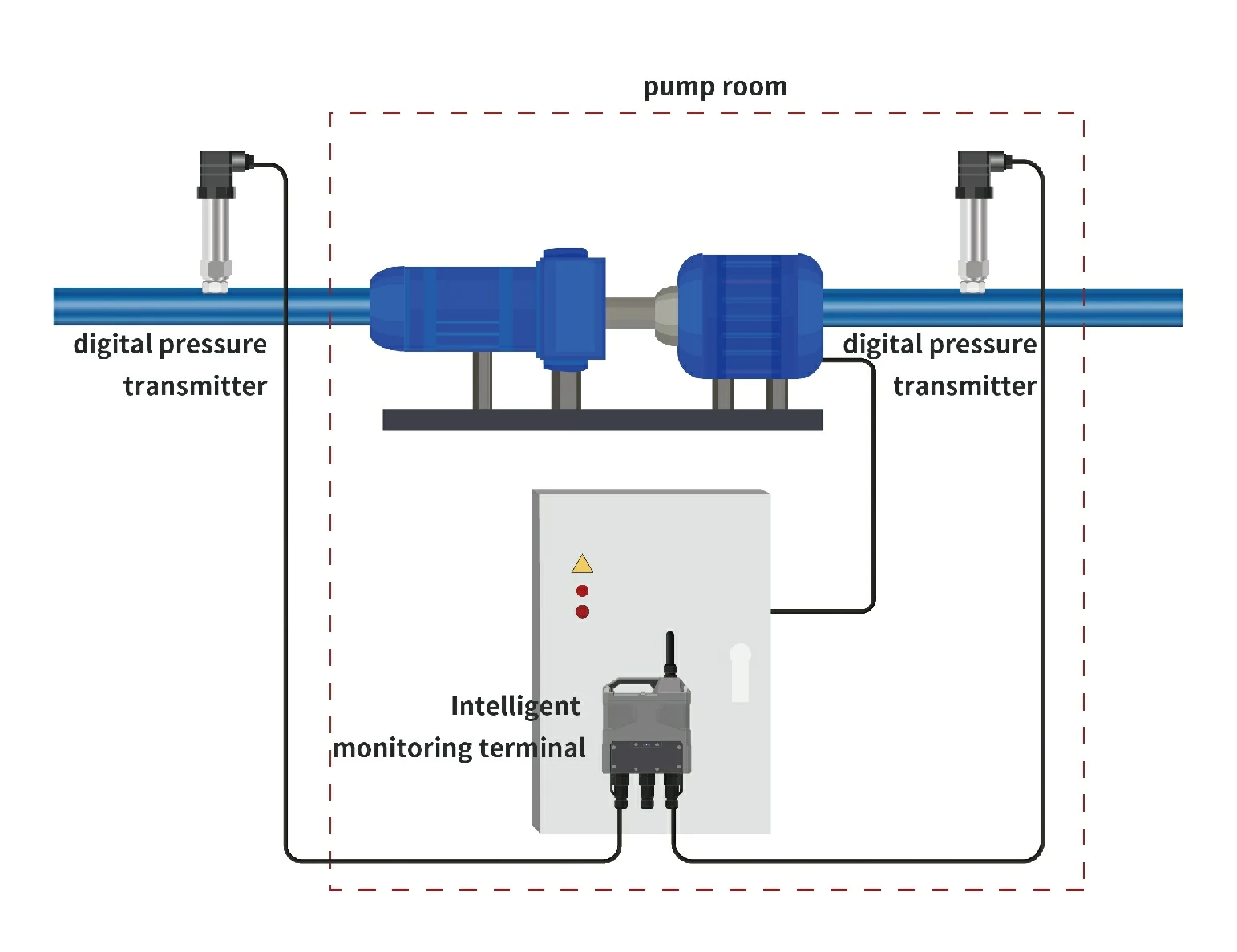

Various monitoring instruments are installed in the water storage tanks, pools, and pipelines of the water supply pump station to monitor the operation of the facilities in real-time. Through advanced cloud computing and big data technology, production data is integrated for timely alarms and early warnings.

more info...

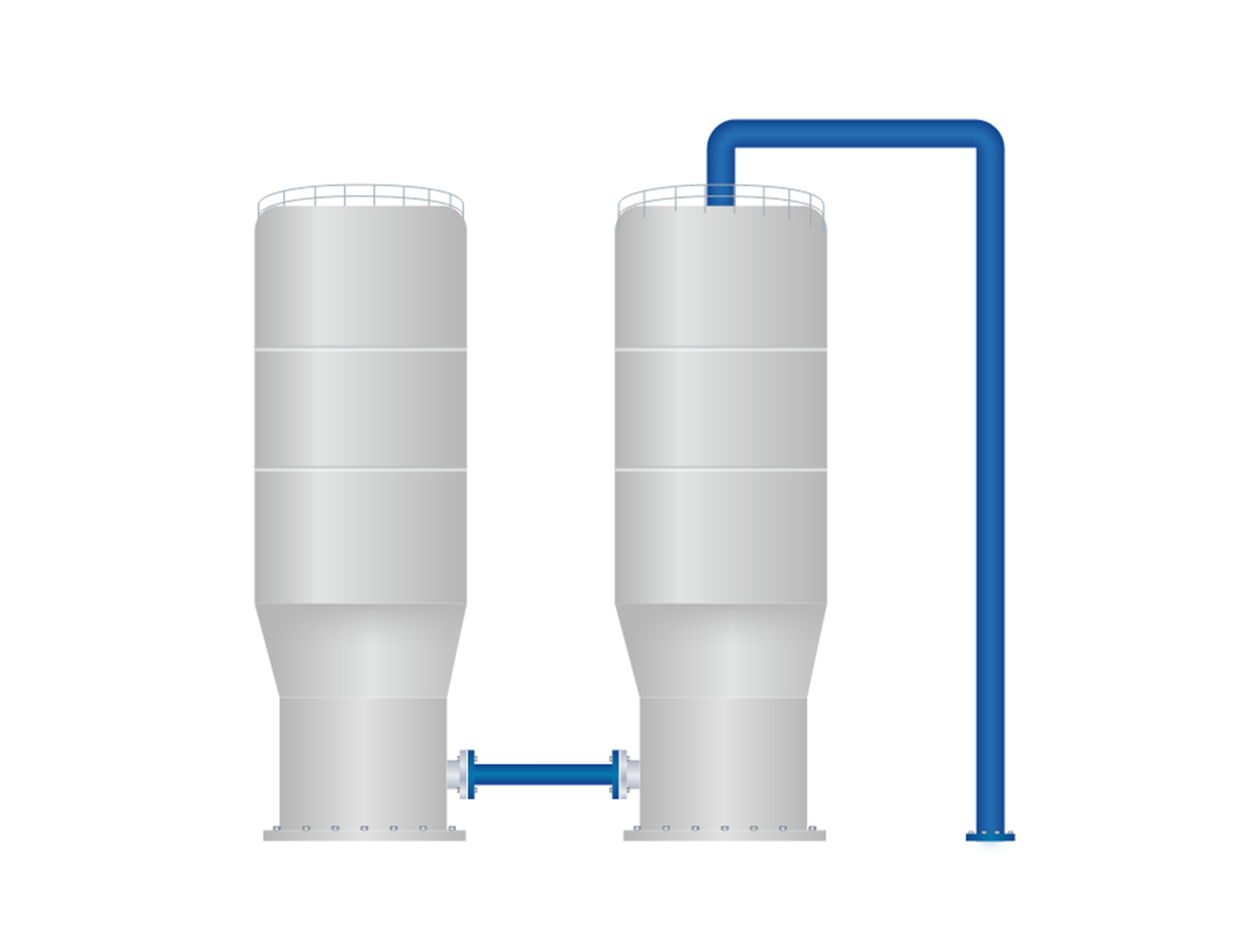

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

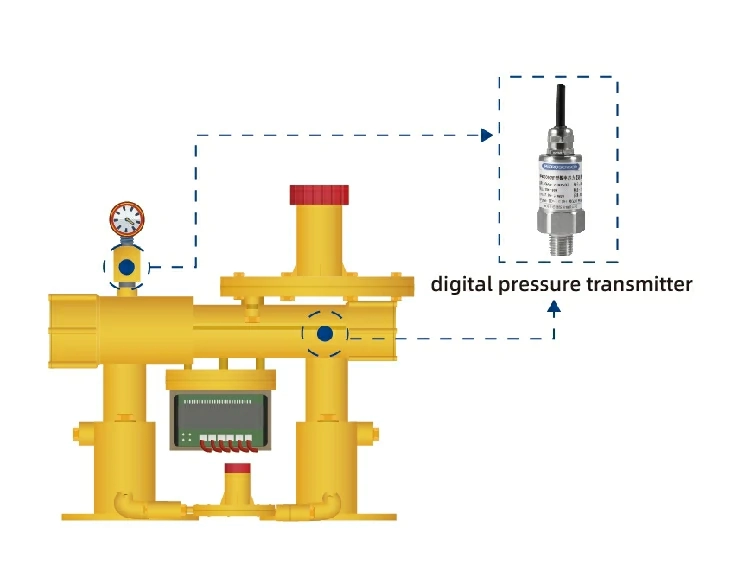

The main function of the gas regulator is to adjust the higher gas inlet pressure to the set lower gas outlet pressure. With a series of changes in gas consumption and inlet pressure, the gas regulator will automatically keep the outlet pressure value within a certain range and play a stabilising role. The pressure transmitter is the core component of the regulator.

more info...