Flow Switch

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MFE600E

Used For

Water Supply and Drainage, Water Conservancy, Paper, Chemical, Metallurgy, Food, Environmental Protection

Leave a MessageMFE600E Electromagnetic Flowmeter is based on Micro Sensor's professional electromagnetic flowmeter production equipment line. All magnetic flowmeters use a water tower up to 37m as a pressure stabilizer for actual flow calibration. At the same time, we also use the standard table method to calibrate the production line. MicroSensor offers optional installation types for flow monitoring in various scenarios.

The product can measure pipe diameters ranging from DN6 to DN1600. MEF600E has an intuitive display and convenient operation, which saves the trouble of on-site installation, operation, and maintenance. MicroSensor has mass production capabilities and can complete special order production at the fastest speed. Our production line can fully meet the production reserve needs of the project products.

Features

• Simple structure and easy installation

• Stable and accurate measurement

• Backlit display

• Easy operation and data query

Image:

MFE600E Electromagnetic Flowmeter is based on Micro Sensor's professional electromagnetic flowmeter production equipment line. All magnetic flowmeters use a water tower up to 37m as a pressure stabilizer for actual flow calibration. At the same time, we also use the standard table method to calibrate the production line. MicroSensor offers optional installation types for flow monitoring in various scenarios.

The product can measure pipe diameters ranging from DN6 to DN1600. MEF600E has an intuitive display and convenient operation, which saves the trouble of on-site installation, operation, and maintenance. MicroSensor has mass production capabilities and can complete special order production at the fastest speed. Our production line can fully meet the production reserve needs of the project products.

Features

• Simple structure and easy installation

• Stable and accurate measurement

• Backlit display

• Easy operation and data query

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

Diameter: DN200 ~ DN1600

Accuracy: ±2.5%

Convenient for maintenance and repair

Pressure port: ANSI 1/2 NPT, JIS G1/2

Diameter: DN25 ~ DN400

Structure type: separated type, integrated type

Flange: DN10~DN500

Accuracy: ±0.5%, ±1.0%

Corrosion- and wear-resistant electrode and lining materials available

Corrosion- and wear-resistant materials available

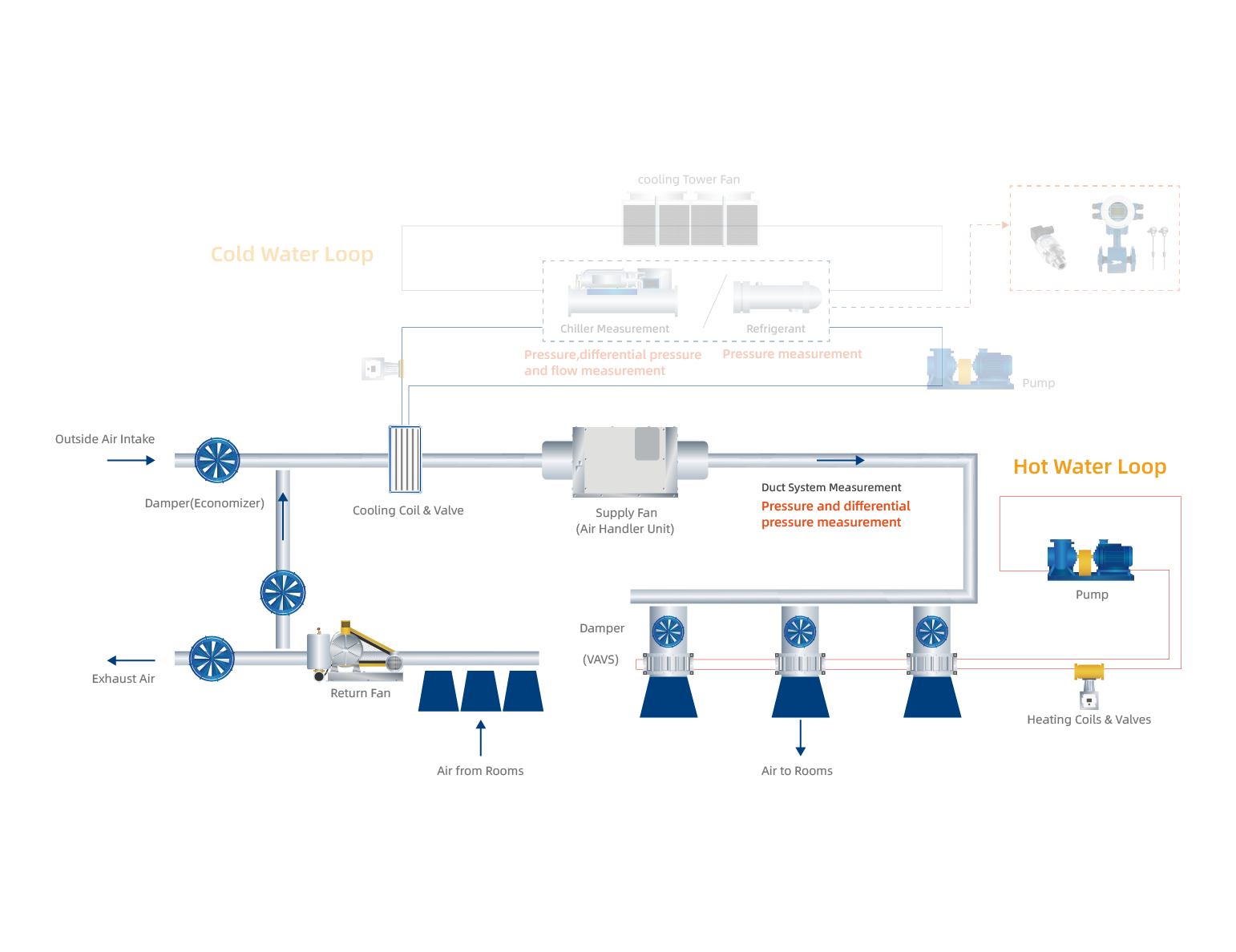

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...

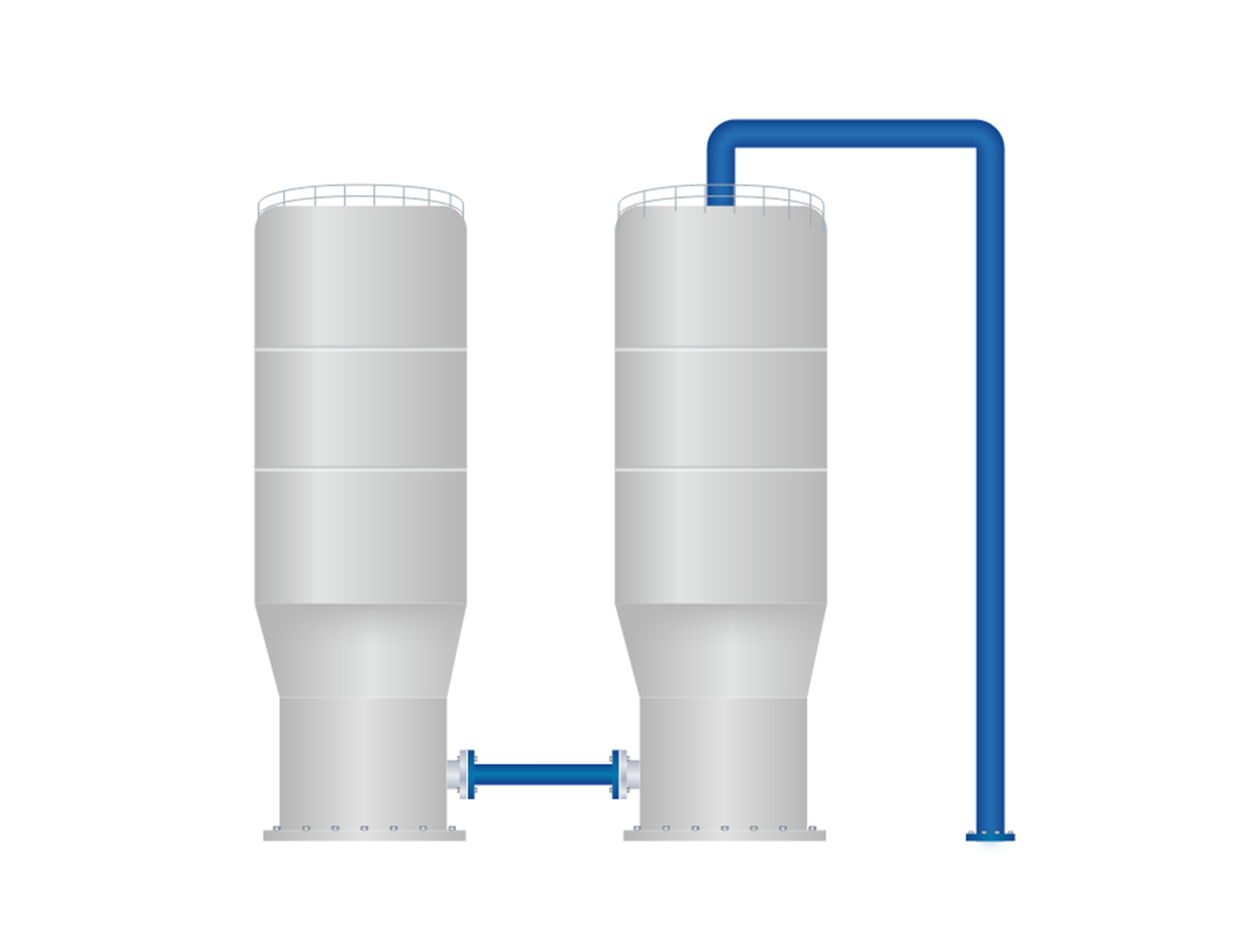

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

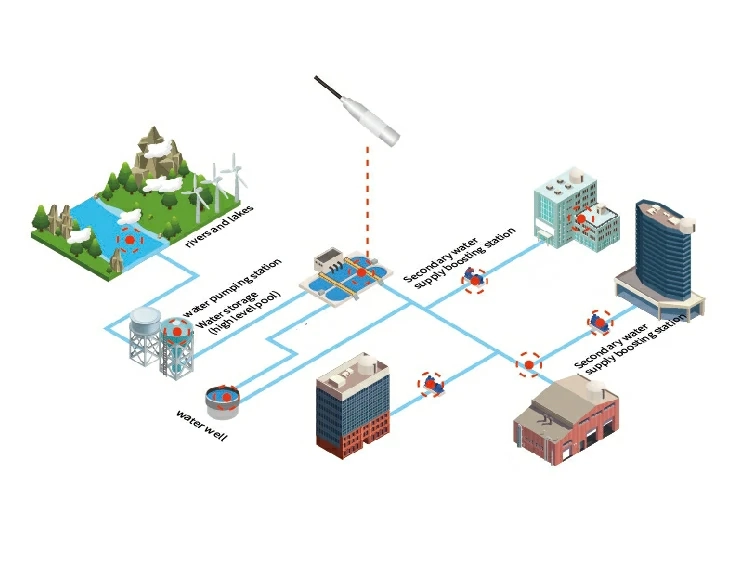

Monitoring the pressure, flow and other specifications of the entire pipe network by installing the monitoring device in water supply pipe network well contributes to scientifically scheduling water supply and ensuring the stable operation of the water supply system.

more info...

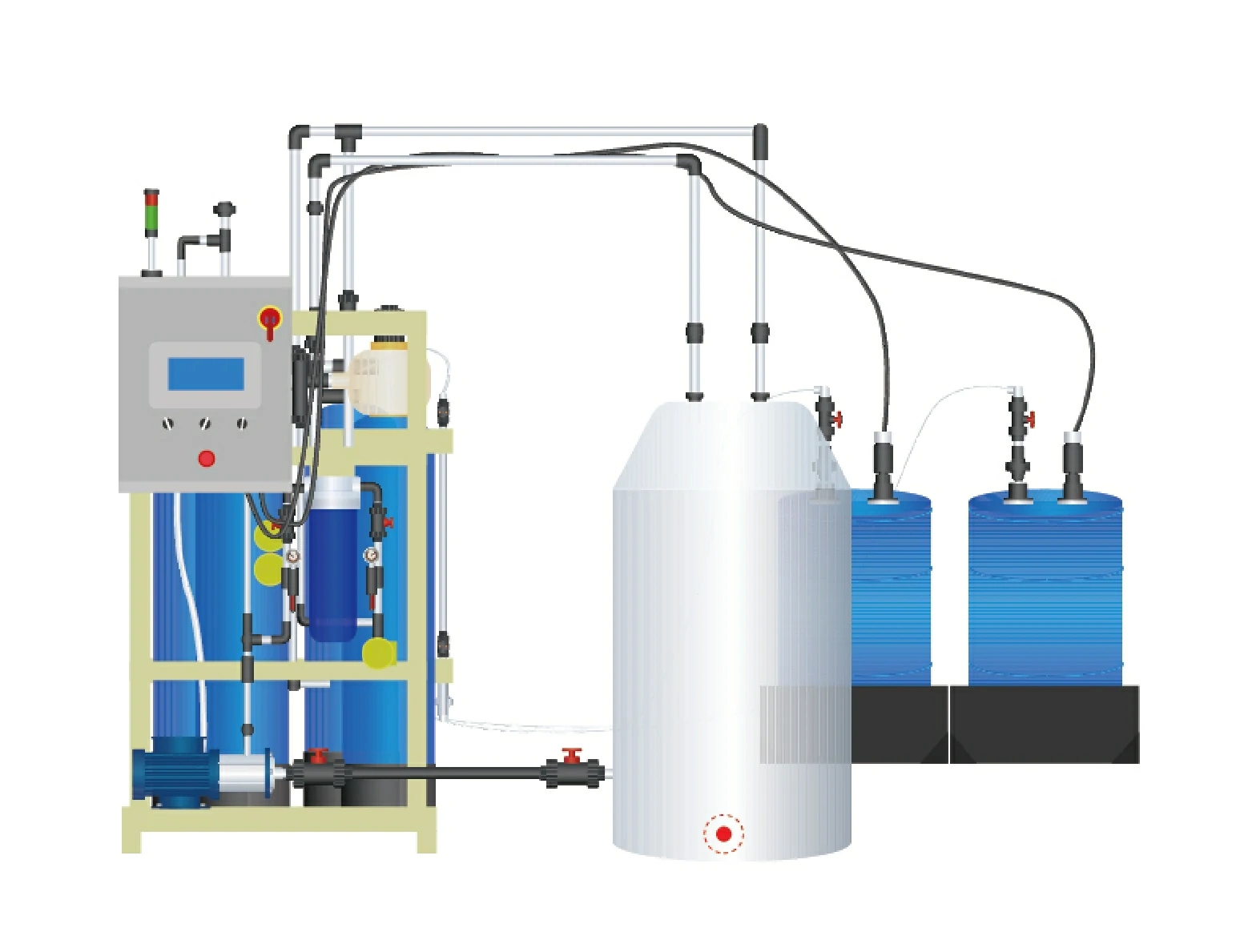

Deionized water is commonly used in industrial manufacturing cleaning processes. The target pressure values should be achieved during the production. It is necessary to monitor the pressure of the inlet and outlet. Only no blockages or leaks ensure normal operation of the production process.

more info...