Flow Switch

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MFE600Z

Used For

Environmental Protection, Heating Field, Building Automation

Leave a MessageThe MFE600Z electromagnetic flowmeter is a high-performance product whose measurement accuracy is unaffected by changes in fluid density, viscosity, temperature, pressure and electrical conductivity. Corrosion- and wear-resistant materials ensure that users can use it for a long time. There is no mechanical inertia, high sensitivity, and the converter uses a single chip with low power consumption to process data, ensuring reliable performance, high accuracy and low power consumption.

Features

• High Measurement Accuracy: Multi-electrode structure ensures high accuracy up to ±0.5%, ±1.0%

• Good Stability: The accuracy isn't influenced by the fluid density, viscosity, temperature, pressure and electrical conductivity changes.

• High Reliability: Open flow without moving parts in measuring pipe, no pressure loss; The converter uses a low-power consumption single-chip for processing data which ensures reliable performance, high accuracy, low power consumption and zero stability.

• Open flow without moving parts in measuring pipe, no pressure loss;

• Multi-electrode structure ensures high accuracy. With the grounding electrode, it doesn't need grounding ring which saves the cost;

• When power off, EEPROM can protect parameter setting and cumulative values

Specifications

• Pressure port: ANSI 1/2 NPT, JIS G1/2, ISO M20 ×1.5

• Diameter: Flange type: DN10~DN500

• Structure type Integrated type, separated type (cable length of separated type≤100m)

• Electrode material: 316L, Ti, HB/HC, Ta, WC, Pt

Image:

The MFE600Z electromagnetic flowmeter is a high-performance product whose measurement accuracy is unaffected by changes in fluid density, viscosity, temperature, pressure and electrical conductivity. Corrosion- and wear-resistant materials ensure that users can use it for a long time. There is no mechanical inertia, high sensitivity, and the converter uses a single chip with low power consumption to process data, ensuring reliable performance, high accuracy and low power consumption.

Features

• High Measurement Accuracy: Multi-electrode structure ensures high accuracy up to ±0.5%, ±1.0%

• Good Stability: The accuracy isn't influenced by the fluid density, viscosity, temperature, pressure and electrical conductivity changes.

• High Reliability: Open flow without moving parts in measuring pipe, no pressure loss; The converter uses a low-power consumption single-chip for processing data which ensures reliable performance, high accuracy, low power consumption and zero stability.

• Open flow without moving parts in measuring pipe, no pressure loss;

• Multi-electrode structure ensures high accuracy. With the grounding electrode, it doesn't need grounding ring which saves the cost;

• When power off, EEPROM can protect parameter setting and cumulative values

Specifications

• Pressure port: ANSI 1/2 NPT, JIS G1/2, ISO M20 ×1.5

• Diameter: Flange type: DN10~DN500

• Structure type Integrated type, separated type (cable length of separated type≤100m)

• Electrode material: 316L, Ti, HB/HC, Ta, WC, Pt

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

Diameter: DN6~DN1600

CE, ATEX approved

Flange, sanitary, threaded, clamping type available

Diameter: DN200 ~ DN1600

Accuracy: ±2.5%

Convenient for maintenance and repair

Pressure port: ANSI 1/2 NPT, JIS G1/2

Diameter: DN25 ~ DN400

Structure type: separated type, integrated type

Pressure transmitters, level transmitters, and mass flow meters are installed in fuel tanks to provide real-time monitoring of fuel levels and pressure. Users can track current location and fuel consumption, access historical vessel data, calculate voyage distance and total fuel usage, and analyze operational efficiency.

more info...

By monitoring the sewage flow, pipeline pressure and reservoir level, the efficiency of sewage treatment plant can be improved. At the same time, it can also facilitate operation and management, and achieve energy saving and automation control.

more info...

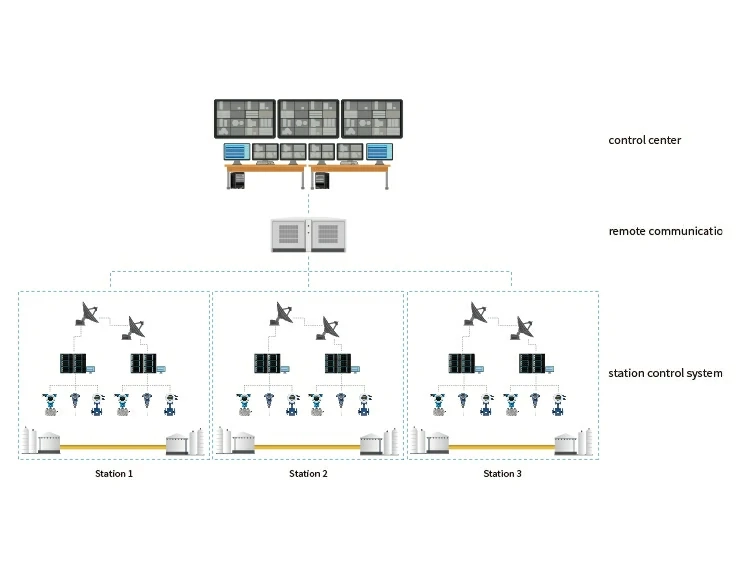

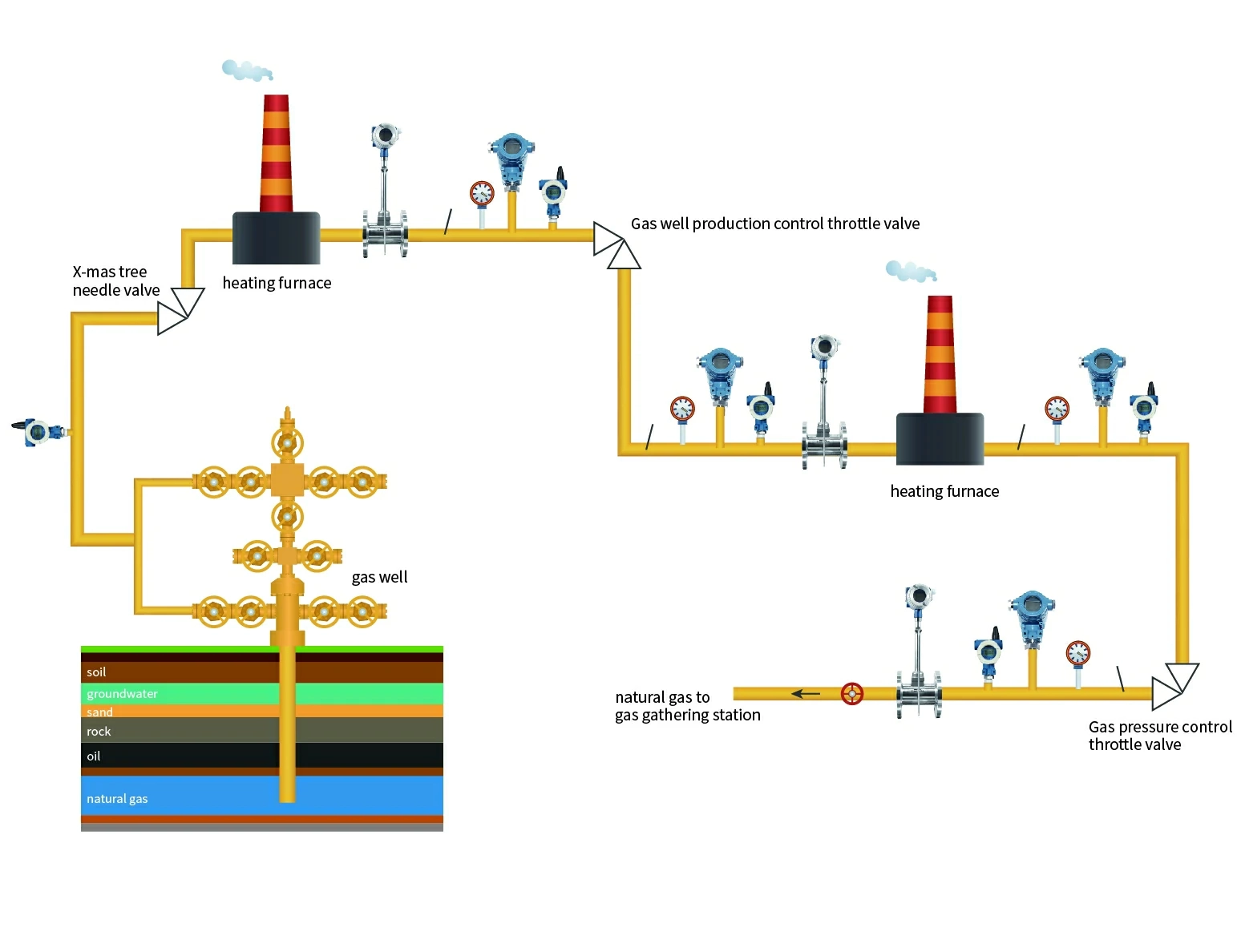

During the process of oil and gas transportation, it is necessary to collect and analyze production and security data related to pipelines and production sites, and generally a supporting SCADA system needs to be built simultaneously. The SCADA system can monitor, control and manage the flow rate, pressure and temperature of the entire pipeline in real time, in order to achieve safe transportation, reduce consumption and improve economic efficiency.

more info...

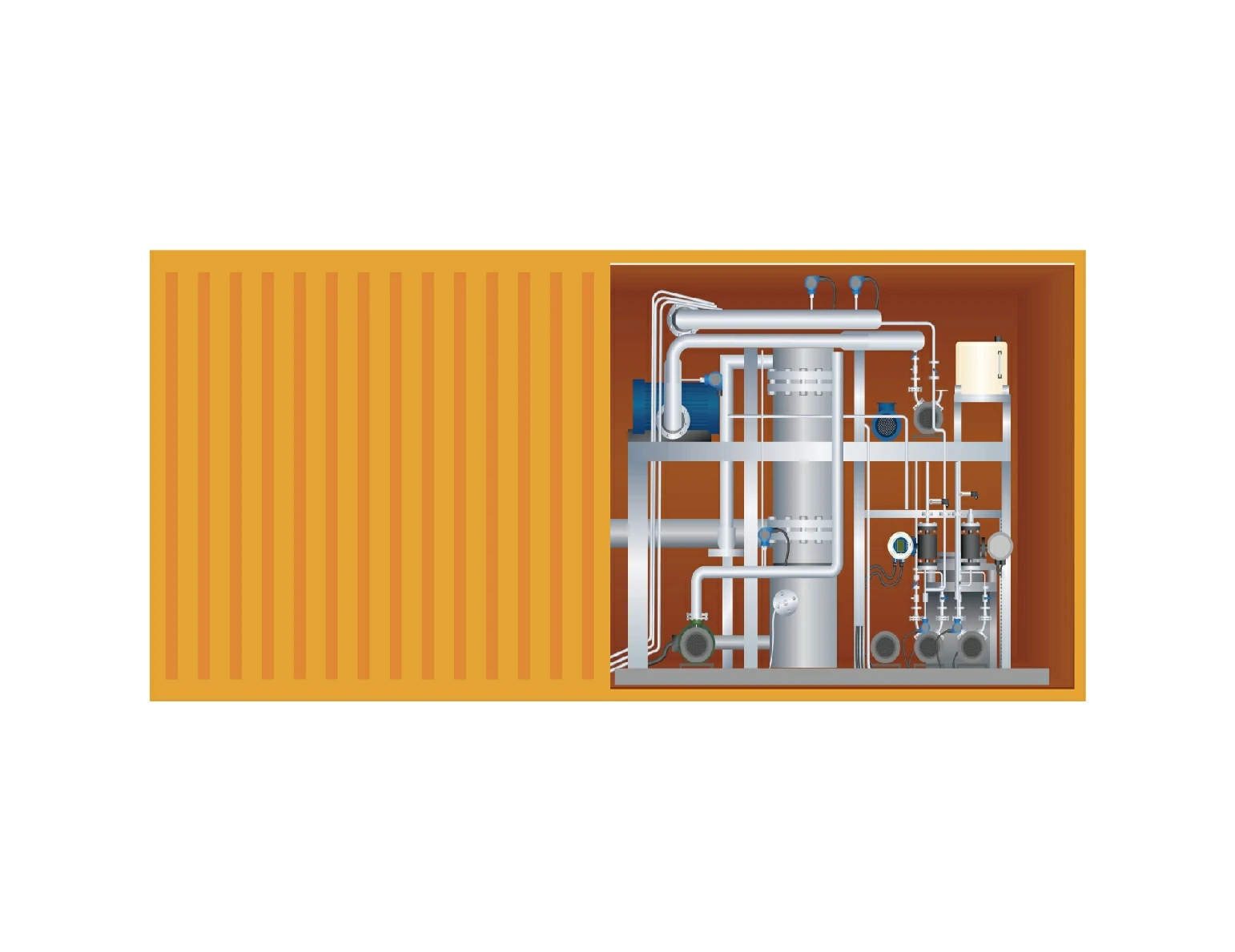

Centralizing the oil and gas produced by scattered oil wells, processing and initial processing, and exporting it after meeting the standards. The process requires multiple steps, including oil and gas separation, crude oil dehydration, and natural gas purification, thus requiring various instruments to measure production parameters.

more info...