Flow Switch

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MFE600H

Used For

Measurement of Central Heating, Heating, Air Conditioning and Other Heat in Civil Residential Quarters, Office Buildings and Enterprises and Institutions

Leave a MessageMFE600H series electromagnetic flowmeter is made by Micro Sensor. Among them, the energy meter has the function of measuring cold quantity and heat quantity, and it comes with 2 Pt1000 as standard, which does not need extra totaliser, and is easy to install, which can reduce the installation cost. The converter adopts low-power single-chip microcomputer to process data, and adopts SMD electronic components and surface mount SMT technology, which has reliable performance, high accuracy, low power consumption and stable zero point.

The product is practical and complete, intuitive display, easy to operate. Saves the trouble of on-site installation, operation and maintenance.

Features

• Multi-electrode structure, highly accurate. With the grounding electrode, it doesn't need grounding ring which saves the cost;

• When power off , EEPROM can protect parameter setting and cumulative values;

• The electromagnetic energy meter has no mechanical inertia, has a sensitive response, can measure instantaneous pulsating flow, and has

good linearity;

• Low frequency rectangular wave excitation improves flow stability, low power loss and excellent low flow rate characteristics.

Specifications

• Diameter: Flange type: DN6~DN1600, ≥DN20 with built-in grounding electrode / Wafer type: DN25~DN200 / Threaded type: DN10~DN50 / Clamp type: DN15~DN150

• Pressure Port: ANSI 1/2 NPT, JIS G1/2, ISO M20 ×1.5

• Measurement Accuracy: ±0.2%(DN10~DN350); ±0.5%(DN6~DN1600)

• Output Signal: 4mA~20mA DC / Hart, Frequency, pulse output / RS485

• Electrical Connection: ISO M20×1.5

• IP Protection: IP65; IP67; IP68

• Power Consumption: ≤5W

• Environmental Temp.: -20℃ ~60℃

• Storage temp.: -40℃ ~60℃

• Relative Humidity: 5%~90%

Image:

MFE600H series electromagnetic flowmeter is made by Micro Sensor. Among them, the energy meter has the function of measuring cold quantity and heat quantity, and it comes with 2 Pt1000 as standard, which does not need extra totaliser, and is easy to install, which can reduce the installation cost. The converter adopts low-power single-chip microcomputer to process data, and adopts SMD electronic components and surface mount SMT technology, which has reliable performance, high accuracy, low power consumption and stable zero point.

The product is practical and complete, intuitive display, easy to operate. Saves the trouble of on-site installation, operation and maintenance.

Features

• Multi-electrode structure, highly accurate. With the grounding electrode, it doesn't need grounding ring which saves the cost;

• When power off , EEPROM can protect parameter setting and cumulative values;

• The electromagnetic energy meter has no mechanical inertia, has a sensitive response, can measure instantaneous pulsating flow, and has

good linearity;

• Low frequency rectangular wave excitation improves flow stability, low power loss and excellent low flow rate characteristics.

Specifications

• Diameter: Flange type: DN6~DN1600, ≥DN20 with built-in grounding electrode / Wafer type: DN25~DN200 / Threaded type: DN10~DN50 / Clamp type: DN15~DN150

• Pressure Port: ANSI 1/2 NPT, JIS G1/2, ISO M20 ×1.5

• Measurement Accuracy: ±0.2%(DN10~DN350); ±0.5%(DN6~DN1600)

• Output Signal: 4mA~20mA DC / Hart, Frequency, pulse output / RS485

• Electrical Connection: ISO M20×1.5

• IP Protection: IP65; IP67; IP68

• Power Consumption: ≤5W

• Environmental Temp.: -20℃ ~60℃

• Storage temp.: -40℃ ~60℃

• Relative Humidity: 5%~90%

Range: 1cm/s~150cm/s (water),

3cm/s~300cm/s(oil)

Temperature Compensation LED Indicator

Diameter: DN6~DN1600

CE, ATEX approved

Flange, sanitary, threaded, clamping type available

Diameter: DN200 ~ DN1600

Accuracy: ±2.5%

Convenient for maintenance and repair

Pressure port: ANSI 1/2 NPT, JIS G1/2

Flange: DN10~DN500

Accuracy: ±0.5%, ±1.0%

Corrosion- and wear-resistant electrode and lining materials available

Corrosion- and wear-resistant materials available

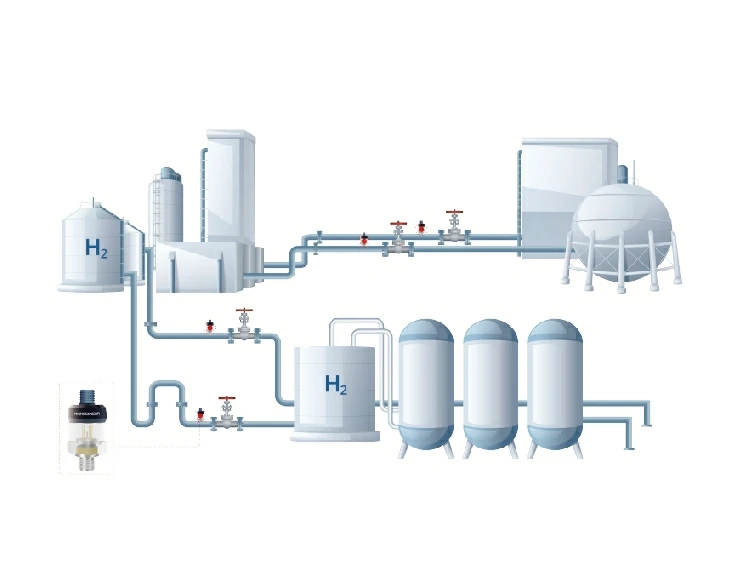

Due to the highly diffusive, flammable, and explosive characteristics of hydrogen, strict pressure monitoring by pressure transmitters is required to ensure its safety during transportation.

more info...

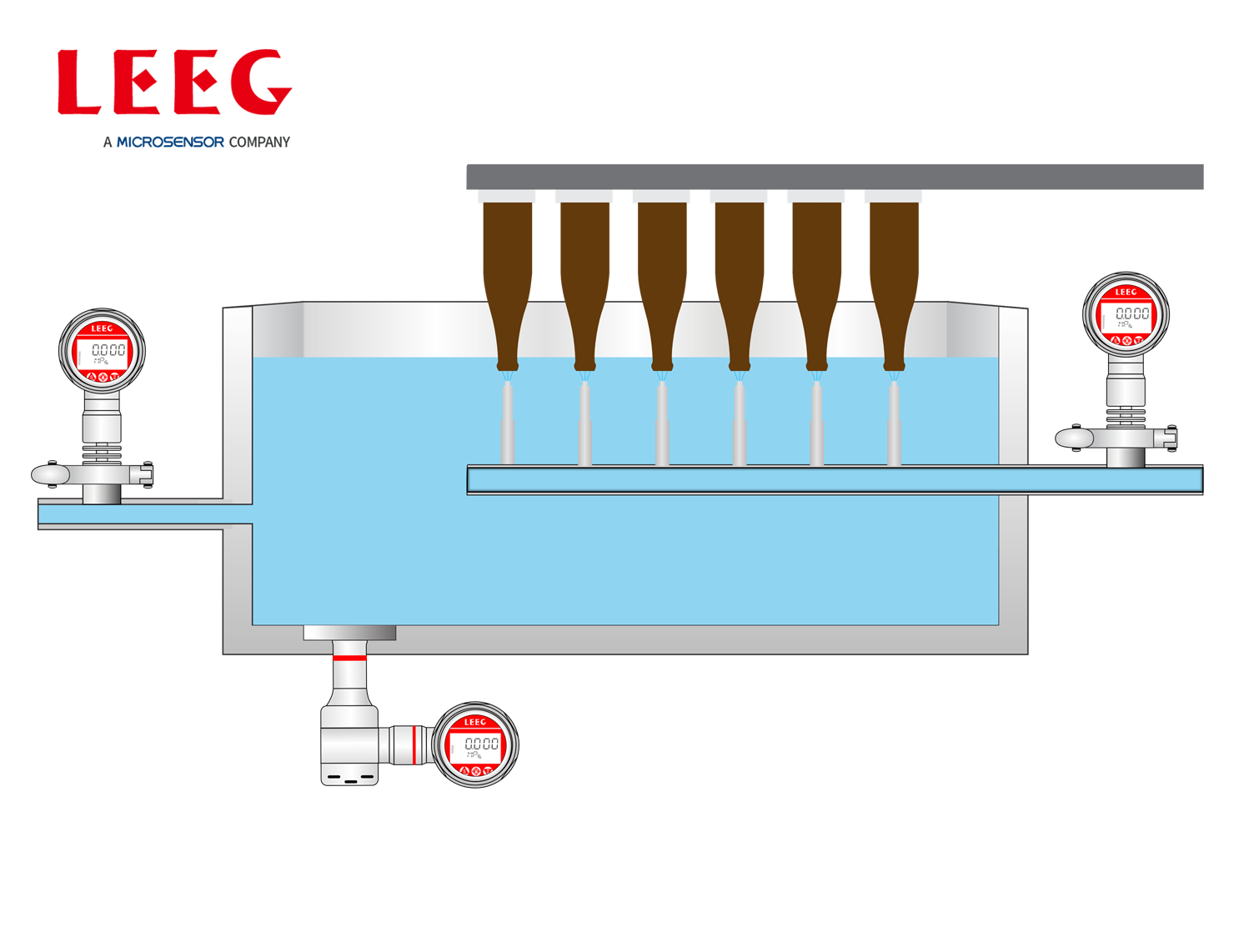

Before beer bottles, medicine bottles, and condiment bottles are filled with liquid, they need to be cleaned first. The cleaning process is as follows: First, the bottles are filled with lye in the alkali tank to remove most of the stains; then, the bottles are back washed with high pressure using water of different temperatures to wash away the remaining impurities and lye. To ensure the stable operation of the bottle washing machine, the level of the alkali tank needs to be measured by hydrostatic pressure. In addition, the pressure of the alkali tank water inlet pipe and the nozzle pipe also needs to be measured.

more info...

The liquid preparation tank is required to prepare various solvents and basic materials for subsequent production, regardless of whether it is to prepare injections, solutions, or detergents, and it needs to proportion different types of purified water, injection water, sucrose solutions, and suspensions. By measuring the liquid level, the filling and dispensing processes are controlled, and pressure measurement is required for the inlet pipelines of different solutions to prevent tank overflow or empty running through measurement.

more info...

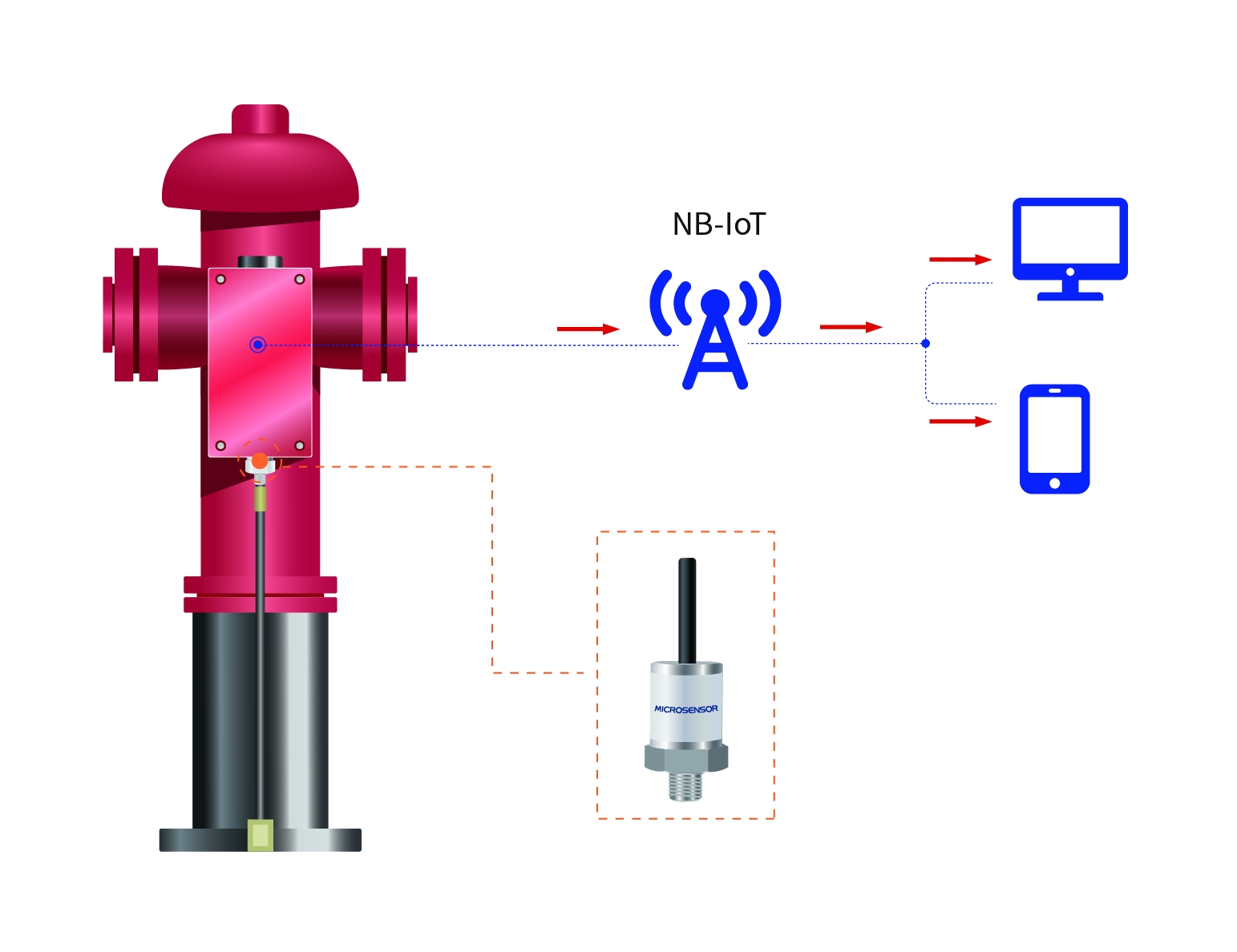

The micro-fused pressure transmitters can be used in hydrants to monitor the internal pressure of hydrants in real time, and send the data to the cloud platform for statistical analysis through wireless monitoring terminals and wireless networks. When an error occurs, it can locate the fault position and sends the alarm in time.

more info...