Pressure Transmitter for Electronic Industry

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MV7000

Used For

The actuation of opening, closing, balancing, and venting operations of differential pressure transmitters and pressure transmitters

Leave a MessageIntroduction

Valve manifolds are devices utilized for the actuation of opening, closing, balancing, and venting operations of differential pressure transmitters and pressure transmitters, controlling specifications such as fluid pressure, flow, and temperature. MV7000 series valve manifolds consists of shut-off valve, two-valve manifold (column), two-valve manifold, three-valve manifold, and five-valve manifold configurations.

Functions

• Shut-off valve (Code: N)

The function of the shut-off valve is to open or shut off the pipeline flow. During installation, it is crucial to ensure that the flow direction of the applicable medium aligns with the arrow direction marked on the valve body.

• Column two-valve manifold (Code: M)

The column two-valve manifold consists of a shut-off valve (for opening, closing or purging) and a vent valve (typically for debris, water, or air). It is crucial to ensure that the flow direction of the applicable medium aligns with the arrow direction marked on the valve body. The shut-off valve and the vent valve are are distributed at 180°.

• Two-valve manifold (Code: 2)

The column two-valve manifold consists of a shut-off valve (for opening, closing or purging) and a vent valve (typically for debris, water, or air). It is crucial to ensure that the flow direction of the applicable medium aligns with the arrow direction marked on the valve body. The shut-off valve and the vent valve are are distributed at 90°.

• Three-valve manifold (Code: 3)

The three-valve manifold consists of a valve body, two shut-off valves, and a balance valve. Based on the function of each valve in the system, it can be categorized as follows: the positive (upstream) globe valve, the negative (downstream) shut-off valve, and the balance valve located in between. The three-valve manifold is used in conjunction with a differential pressure transmitter to establish or isolate communication between the positive and negative pressure measuring chambers and the impulse point, or to isolate or establish communication between the positive and negative pressure measuring chambers.

• Five-valve manifold (Code: 5)

The five-valve manifold is essentially a three-valve manifold with the addition of vent valves on both the high and low-pressure sides.

Image:

Introduction

Valve manifolds are devices utilized for the actuation of opening, closing, balancing, and venting operations of differential pressure transmitters and pressure transmitters, controlling specifications such as fluid pressure, flow, and temperature. MV7000 series valve manifolds consists of shut-off valve, two-valve manifold (column), two-valve manifold, three-valve manifold, and five-valve manifold configurations.

Functions

• Shut-off valve (Code: N)

The function of the shut-off valve is to open or shut off the pipeline flow. During installation, it is crucial to ensure that the flow direction of the applicable medium aligns with the arrow direction marked on the valve body.

• Column two-valve manifold (Code: M)

The column two-valve manifold consists of a shut-off valve (for opening, closing or purging) and a vent valve (typically for debris, water, or air). It is crucial to ensure that the flow direction of the applicable medium aligns with the arrow direction marked on the valve body. The shut-off valve and the vent valve are are distributed at 180°.

• Two-valve manifold (Code: 2)

The column two-valve manifold consists of a shut-off valve (for opening, closing or purging) and a vent valve (typically for debris, water, or air). It is crucial to ensure that the flow direction of the applicable medium aligns with the arrow direction marked on the valve body. The shut-off valve and the vent valve are are distributed at 90°.

• Three-valve manifold (Code: 3)

The three-valve manifold consists of a valve body, two shut-off valves, and a balance valve. Based on the function of each valve in the system, it can be categorized as follows: the positive (upstream) globe valve, the negative (downstream) shut-off valve, and the balance valve located in between. The three-valve manifold is used in conjunction with a differential pressure transmitter to establish or isolate communication between the positive and negative pressure measuring chambers and the impulse point, or to isolate or establish communication between the positive and negative pressure measuring chambers.

• Five-valve manifold (Code: 5)

The five-valve manifold is essentially a three-valve manifold with the addition of vent valves on both the high and low-pressure sides.

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

Range: -1bar…-0.35bar ~ 0bar ~0.35bar…700bar

No need for re-calibration for users, high precision

Customizable dimensions

1 2 5 10 20mH2O;

Accuracy: +0.25%FS (typ.) +0.5%FS(max.);

4~20mADC;0~10/20mADC;0/1~5/10VDC

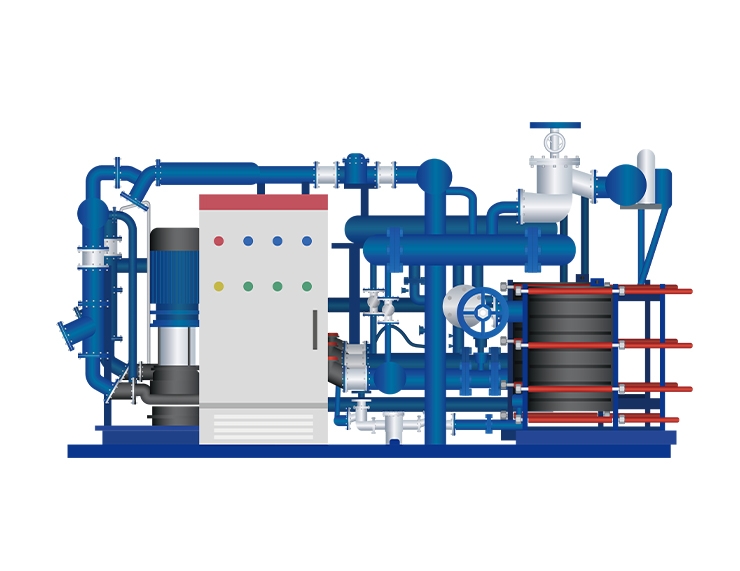

Pressure transmitters, temperature tranmitters and electromagnetic flowmeters are installed in the marine water circulation cooling system to ensure the heat exchange efficiency of the central cooler. By optimizing seawater flow control, energy saving effects are maximized and stable operation of the cooling system is ensured.

more info...

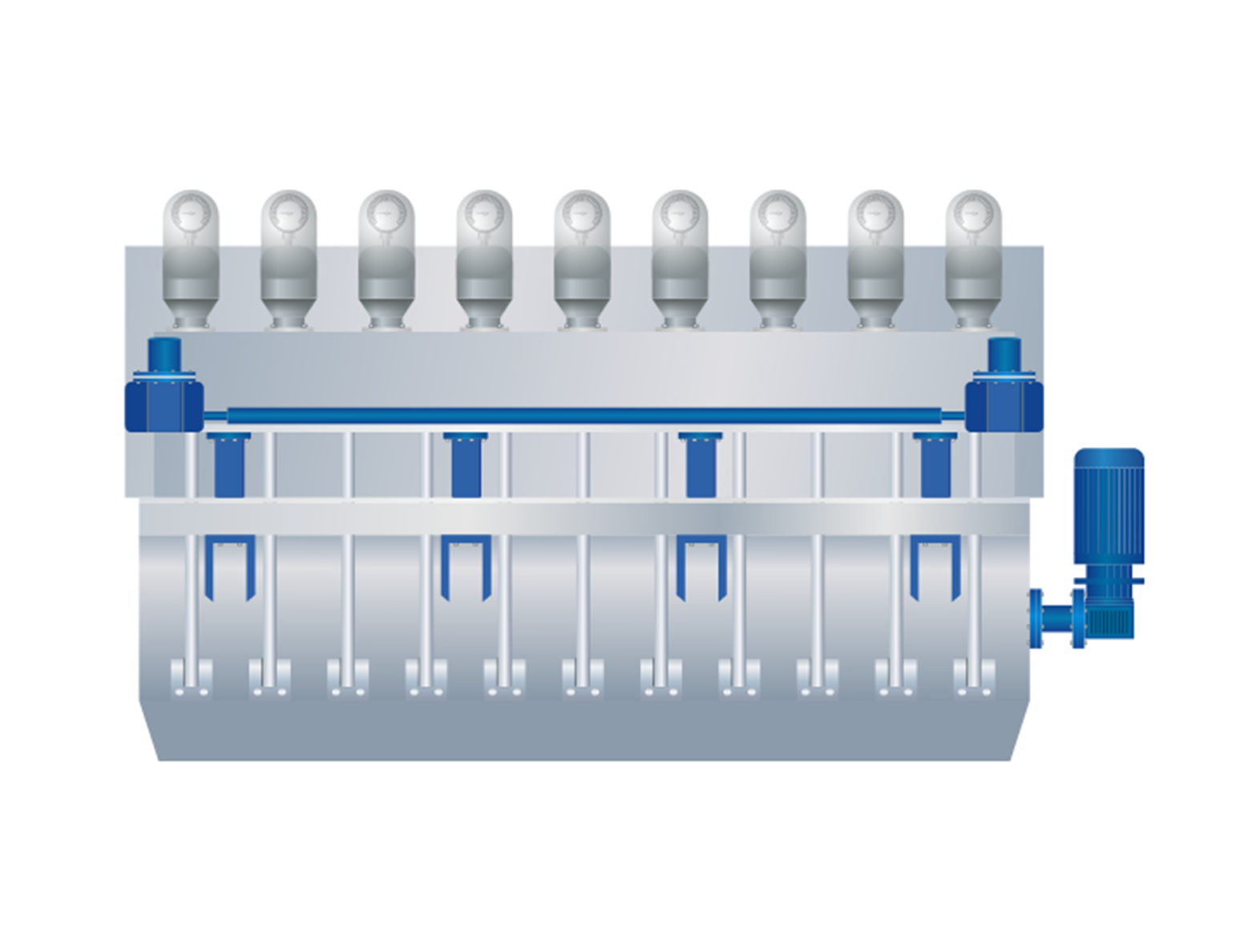

In the papermaking process, pulp is fed into the headbox of the paper machine. In the hydraulic headbox, pulp enters the weir pool via the conical distribution pipe and tube bundles, and is then sprayed onto the forming wire by the weir plate. Since the pulp jet velocity is controlled by adjusting the headbox slice pressure per the wire speed, accurate pressure measurement in the headbox is essential.

more info...

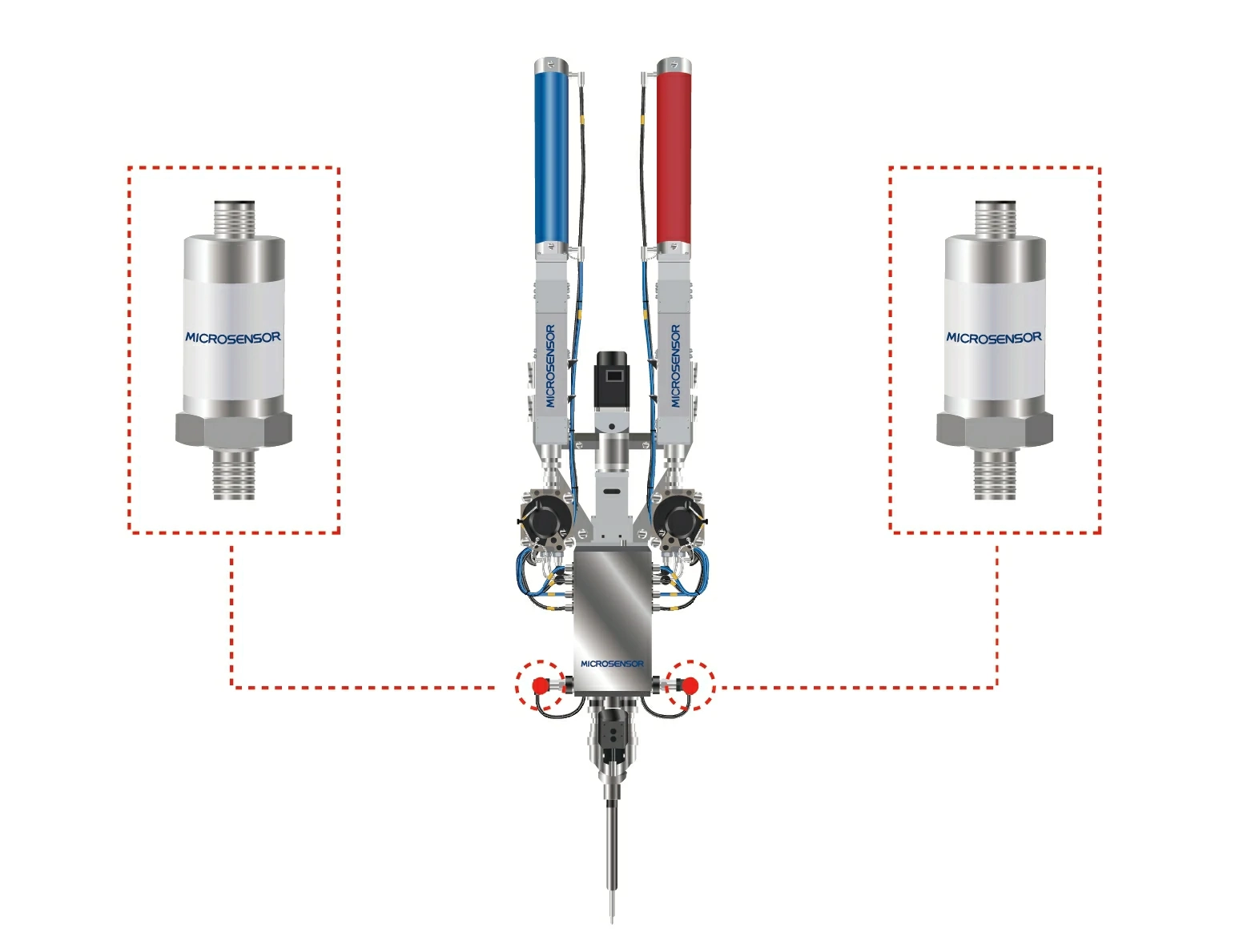

Dispensing machine is used to control adhesive, paint and other liquids. It requires compressed air to be fed into the glue bottle for proper operation. The role of the pressure transmitter is to monitor the pressure at the air inlet to ensure that the dispenser works properly.

more info...

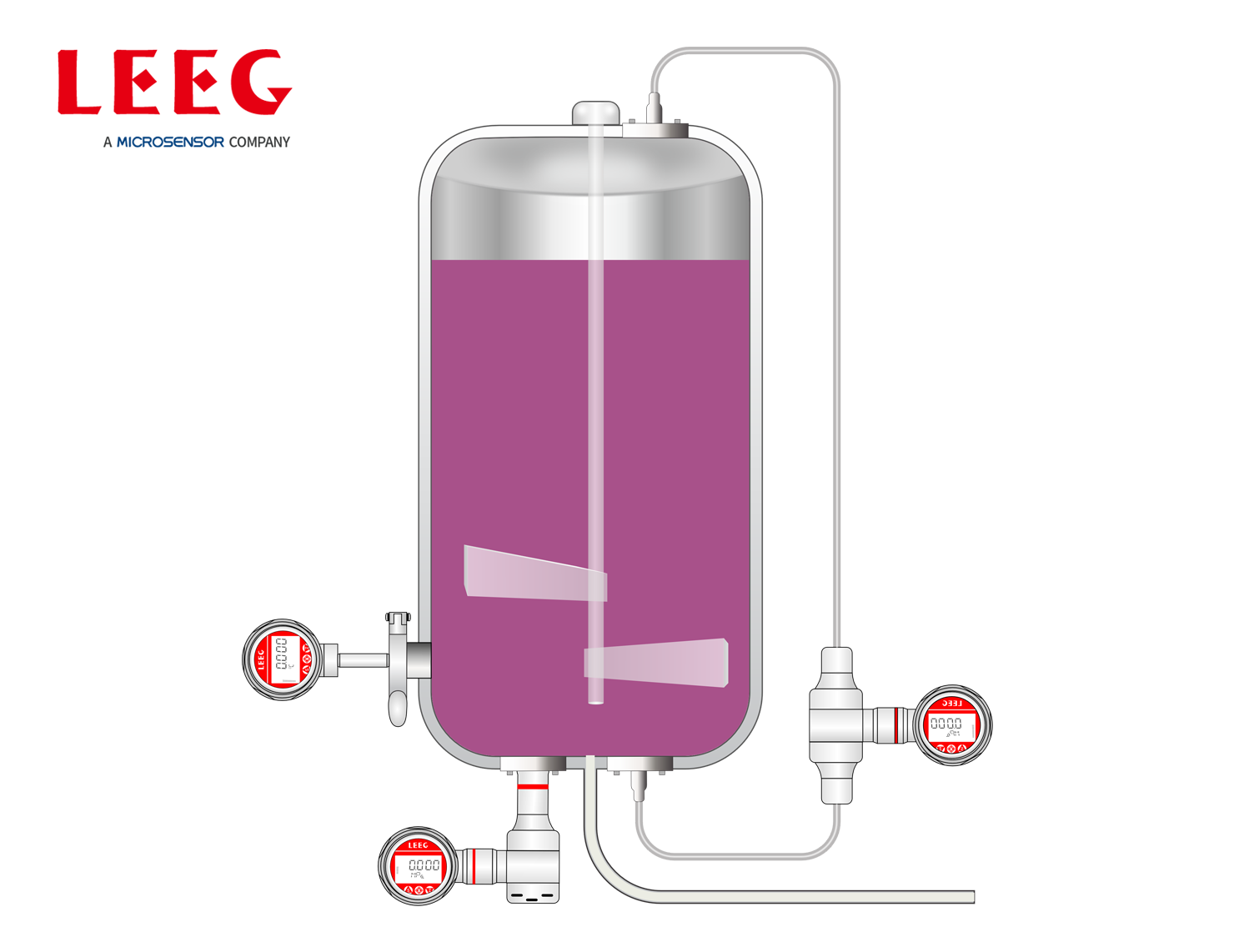

In beverage storage tanks, the role of the liquid level transmitter is to monitor the material inventory in real time by measuring the liquid level height of milk or beverages in the tank; the temperature transmitter measures the temperature of the material in the tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration due to excessively high temperature or affecting the taste of the product due to excessively low temperature.

more info...