Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM416W

Used For

Petroleum, Chemi-Industry, Power Station, Water Supply

Leave a MessageMPM416W Submersible Level Transmitters are special for wasted water and sewage treatment with CE-marked and explosion-proof approved. Anti-corrosive feature ensures MPM416W hydrostatic pressure transmitter can protect from chemicals, acids, etc.

Feature

• High-performance diffused silicon sensing element

• Split structure facilitates installation, adjustment and wiring

• CE certified, compliant with explosion-proof and marine product requirements

Specifications

• Pressure Range: 1, 2, 5, 10, 20, 50, 100, 200mH2O

• Overpressure: 1.5times FS

• Accuracy: +0.25%FS(typ.) +0.5%FS(max.)

• Operation temp.: -30℃ ~80℃

• Protection: IP68(sensor part), IP65(wiring part)

• Ex-proof class: Exia Ⅱ CT6

Image:

MPM416W Submersible Level Transmitters are special for wasted water and sewage treatment with CE-marked and explosion-proof approved. Anti-corrosive feature ensures MPM416W hydrostatic pressure transmitter can protect from chemicals, acids, etc.

Feature

• High-performance diffused silicon sensing element

• Split structure facilitates installation, adjustment and wiring

• CE certified, compliant with explosion-proof and marine product requirements

Specifications

• Pressure Range: 1, 2, 5, 10, 20, 50, 100, 200mH2O

• Overpressure: 1.5times FS

• Accuracy: +0.25%FS(typ.) +0.5%FS(max.)

• Operation temp.: -30℃ ~80℃

• Protection: IP68(sensor part), IP65(wiring part)

• Ex-proof class: Exia Ⅱ CT6

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

more info...

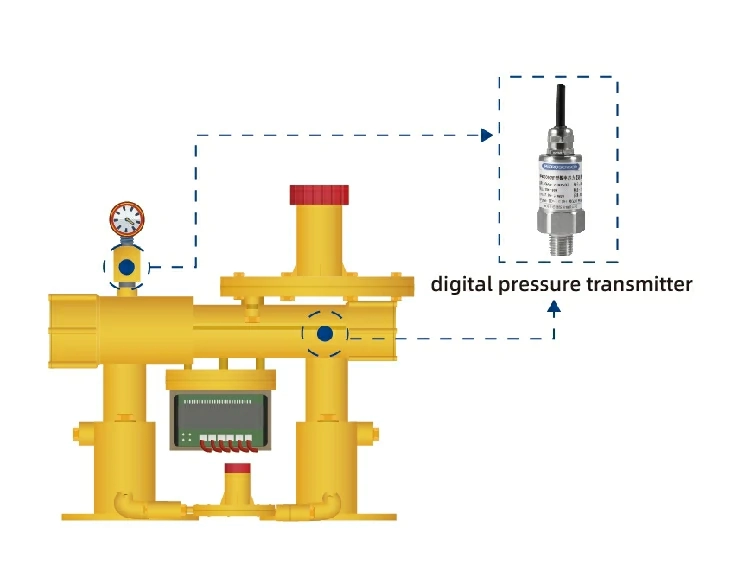

The main function of the gas regulator is to adjust the higher gas inlet pressure to the set lower gas outlet pressure. With a series of changes in gas consumption and inlet pressure, the gas regulator will automatically keep the outlet pressure value within a certain range and play a stabilising role. The pressure transmitter is the core component of the regulator.

more info...

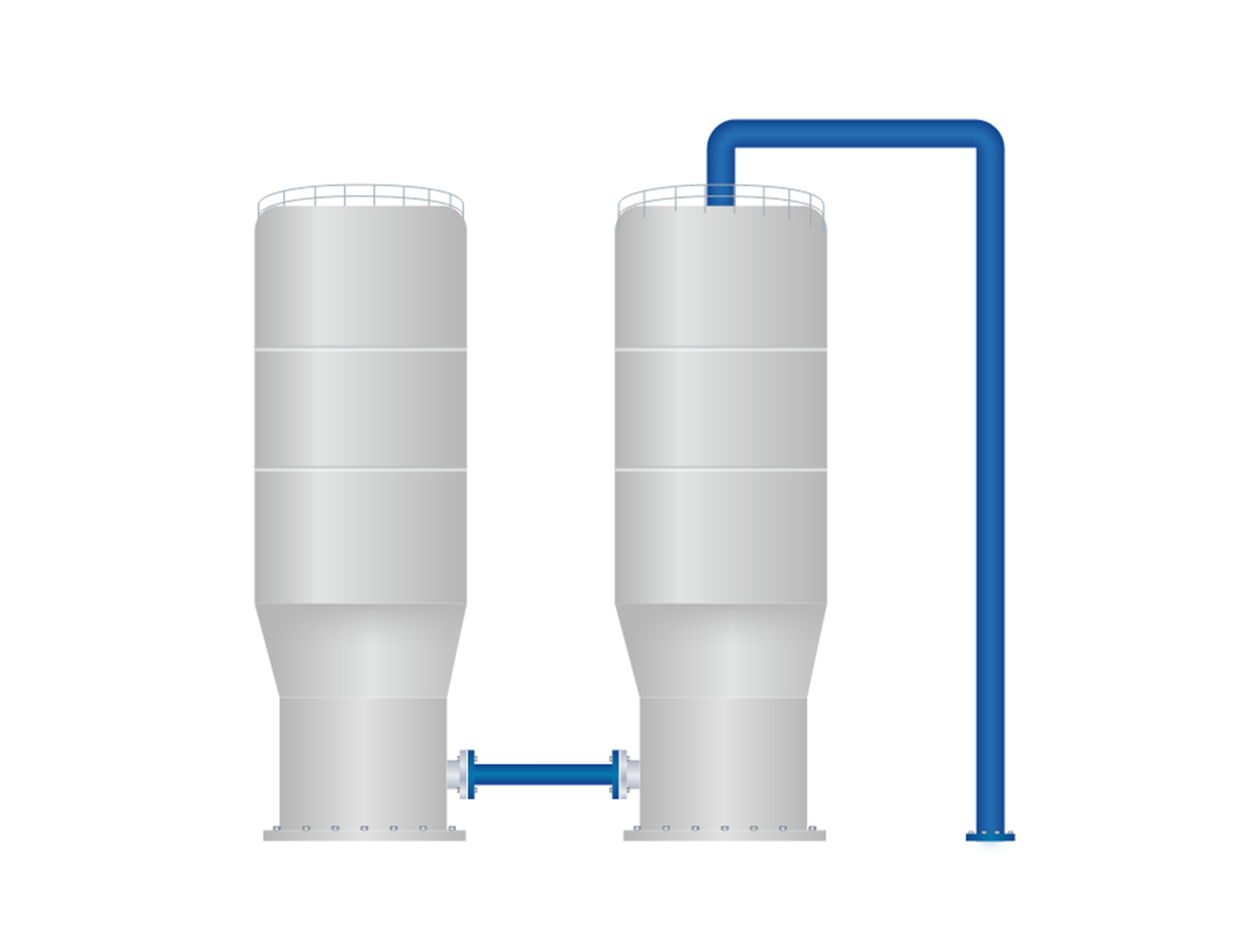

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

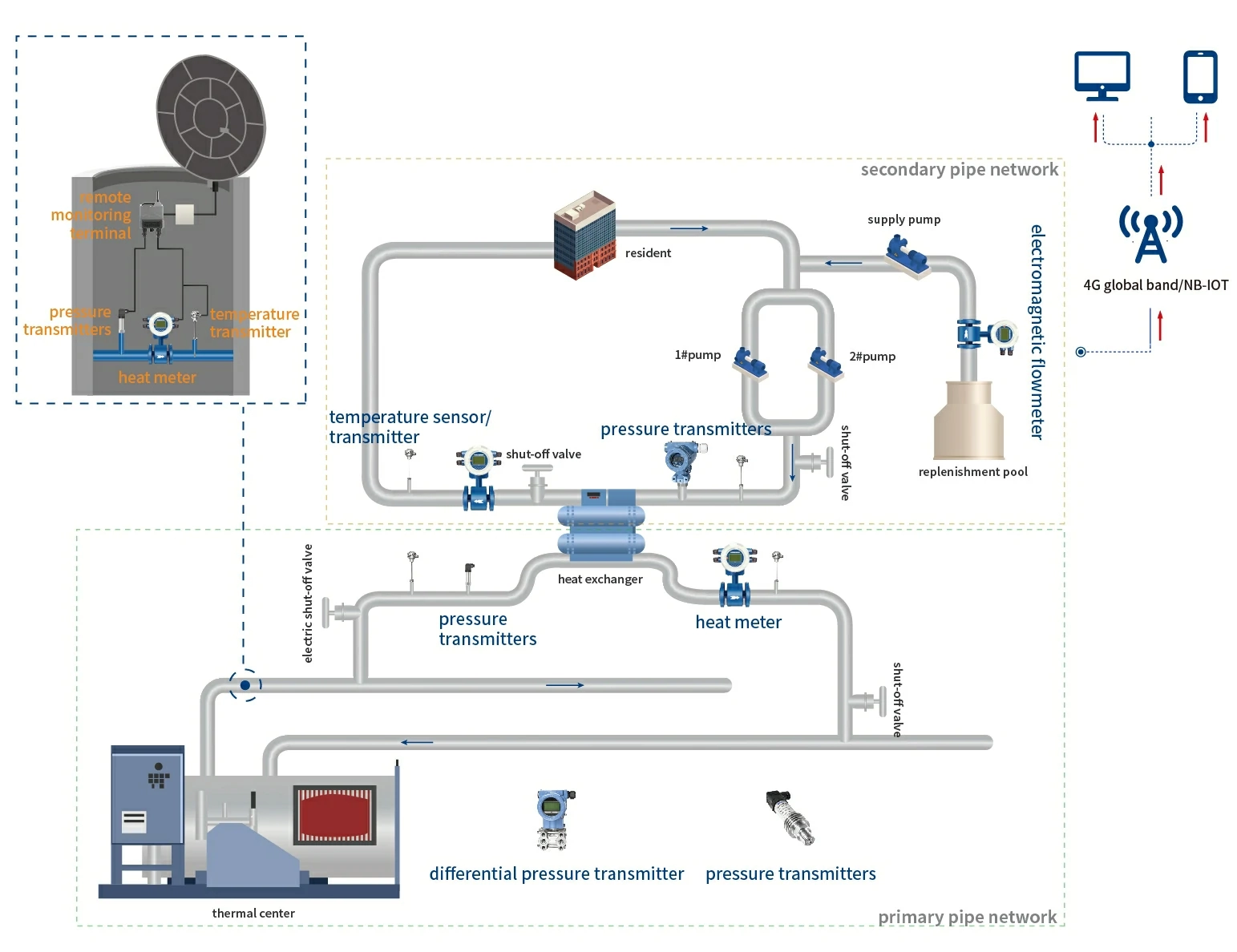

Electromagnetic flowmeters, ultrasonic flowmeters, level transmitters, pressure transmitters are installed in the heat exchange station heating system to obtain real-time data on pipeline flow, heat, temperature, and pressure, ensuring the normal operation of the heat exchange station.

more info...