17mm Submersible Level Transmitter

φ17mm

0m~10m…200mH2O

Measurement Accuracy: ±0.5%FS

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

LR725L

Used For

Measurement of Liquid, Slurry, and Solids on Industrial Sites

Leave a MessageThe LR725L Ultrasonic Level Meter adopts the wireless transmission principle without touching the measurement medium. The ultrasonic level transmitter uses the speed of sound waves to calculate liquid level. The high and stable measurement accuracy is owned by the constant speed of sound wave transmission. LR725L can measure liquid levels up to 50m. The products adapt to different industrial application scenarios' requirements, including corrosive and high-temperature liquids. MicroSensor LR725L non-contact liquid level transmitter is with simple installation and easy maintenance. It is widely used in industrial field measurement of liquids and slurries.

Features

• Contactless Level Meter

• Highly efficient and low-cost measuring equipment

• Wide measuring range: 1m~50m

• IP68 Probe protection level

Specification

• Level range: 5m, 10m, 15m, 20m, 30m, 40m, 50m

• Accuracy: ±0.5%FS~±1.0%FS

• Resolution: 3mm or ±0.1% (max. value is valid)

• Display: English LCD display

• Analog output: 4mA~20mA DC (510Ω load)

• Relay output: single channel is 2 groups; dual channel is 4 groups AC 250V/8A or DC 30V/5A state programmable (optional)

• Power supply: 220V AC (±15%, default) / 24V DC 120mA (optional) / 12V DC, 9V DC, battery powered (customized)

• Ambient temperature: display instrument -20℃ ~60℃, probe -20℃ ~80℃

• Communication interface: RS485 RS232 optional (manufacturer’s protocol)

• Protection: Indicator IP65 (integrated type)

Converter IP65, probe IP68 (separated type)

• Probe cable: up to 100m without electromagnetic interference, 10m as standard (separated type only)

• Probe installation: according to range and probe selection

Image:

The LR725L Ultrasonic Level Meter adopts the wireless transmission principle without touching the measurement medium. The ultrasonic level transmitter uses the speed of sound waves to calculate liquid level. The high and stable measurement accuracy is owned by the constant speed of sound wave transmission. LR725L can measure liquid levels up to 50m. The products adapt to different industrial application scenarios' requirements, including corrosive and high-temperature liquids. MicroSensor LR725L non-contact liquid level transmitter is with simple installation and easy maintenance. It is widely used in industrial field measurement of liquids and slurries.

Features

• Contactless Level Meter

• Highly efficient and low-cost measuring equipment

• Wide measuring range: 1m~50m

• IP68 Probe protection level

Specification

• Level range: 5m, 10m, 15m, 20m, 30m, 40m, 50m

• Accuracy: ±0.5%FS~±1.0%FS

• Resolution: 3mm or ±0.1% (max. value is valid)

• Display: English LCD display

• Analog output: 4mA~20mA DC (510Ω load)

• Relay output: single channel is 2 groups; dual channel is 4 groups AC 250V/8A or DC 30V/5A state programmable (optional)

• Power supply: 220V AC (±15%, default) / 24V DC 120mA (optional) / 12V DC, 9V DC, battery powered (customized)

• Ambient temperature: display instrument -20℃ ~60℃, probe -20℃ ~80℃

• Communication interface: RS485 RS232 optional (manufacturer’s protocol)

• Protection: Indicator IP65 (integrated type)

Converter IP65, probe IP68 (separated type)

• Probe cable: up to 100m without electromagnetic interference, 10m as standard (separated type only)

• Probe installation: according to range and probe selection

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

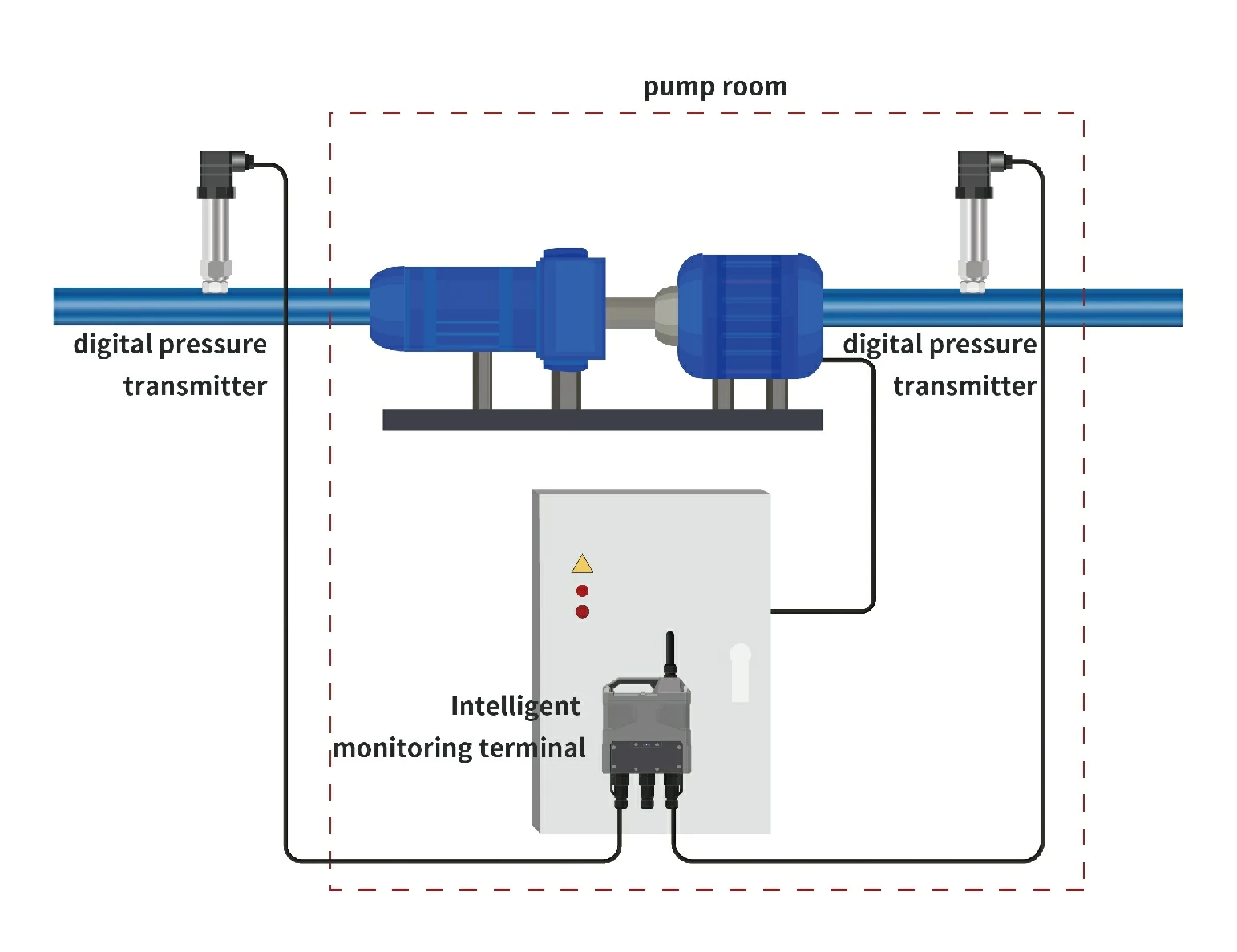

Various monitoring instruments are installed in the water storage tanks, pools, and pipelines of the water supply pump station to monitor the operation of the facilities in real-time. Through advanced cloud computing and big data technology, production data is integrated for timely alarms and early warnings.

more info...

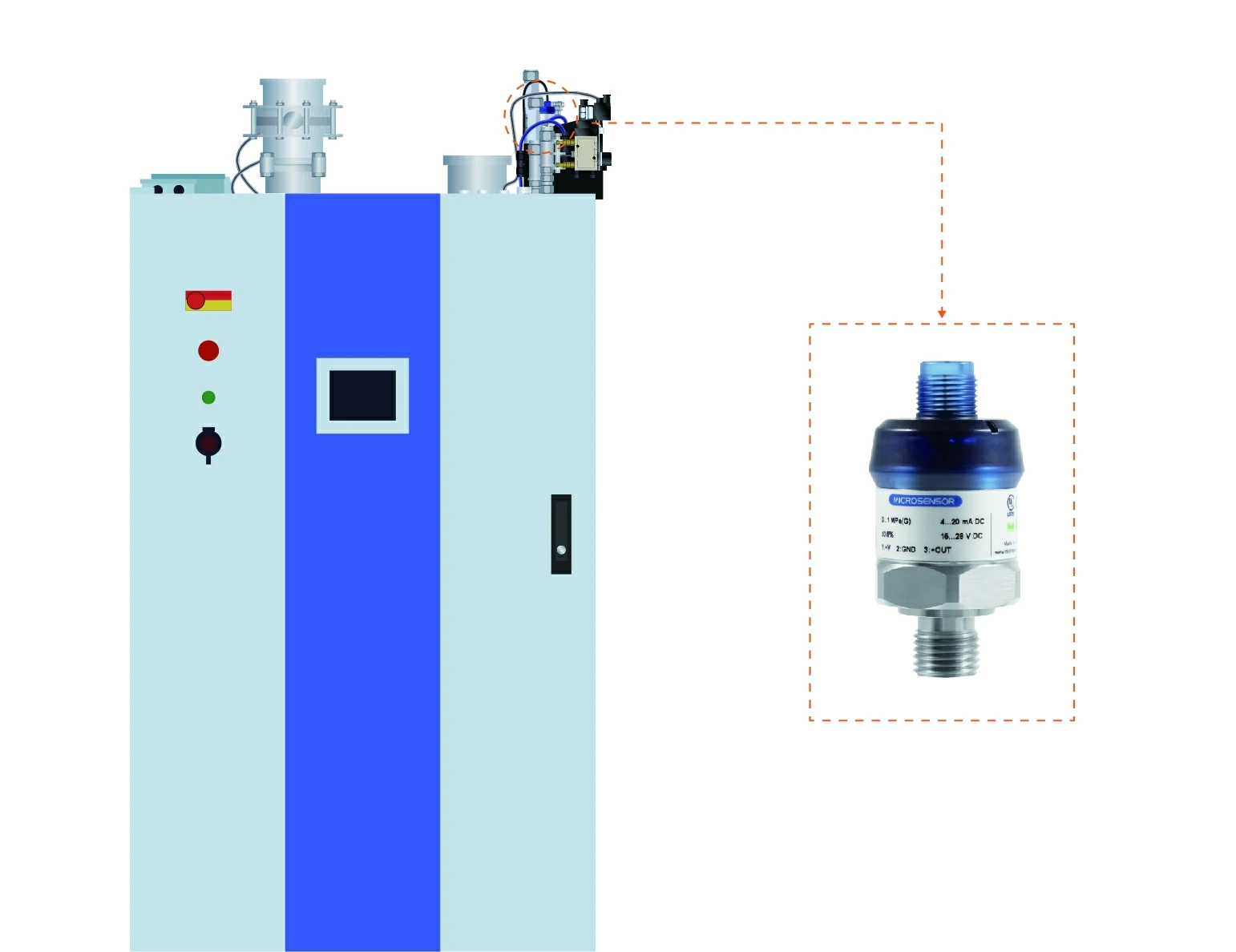

The plasma in a plasma cleaning machine is a state of matter, usually composed of process gases. Therefore, specially designed pressure transmitters must be installed in the relevant gas circuits of the plasma cleaning system to monitor and provide feedback on production data.

more info...

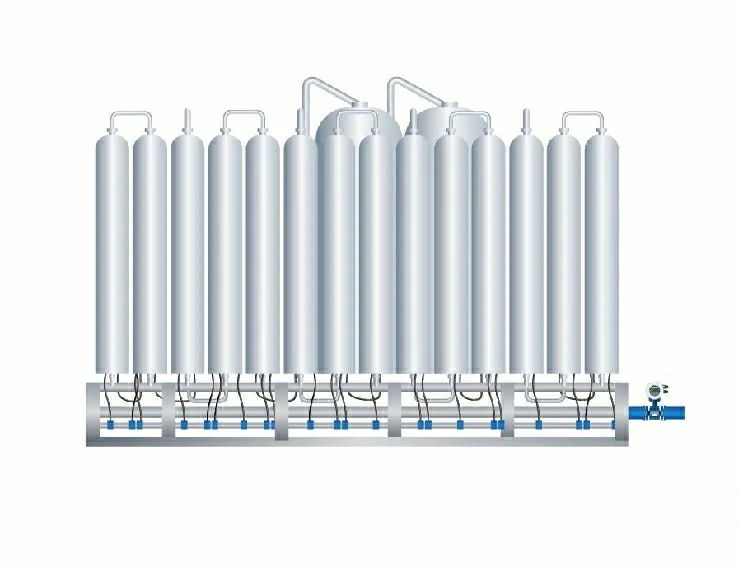

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...

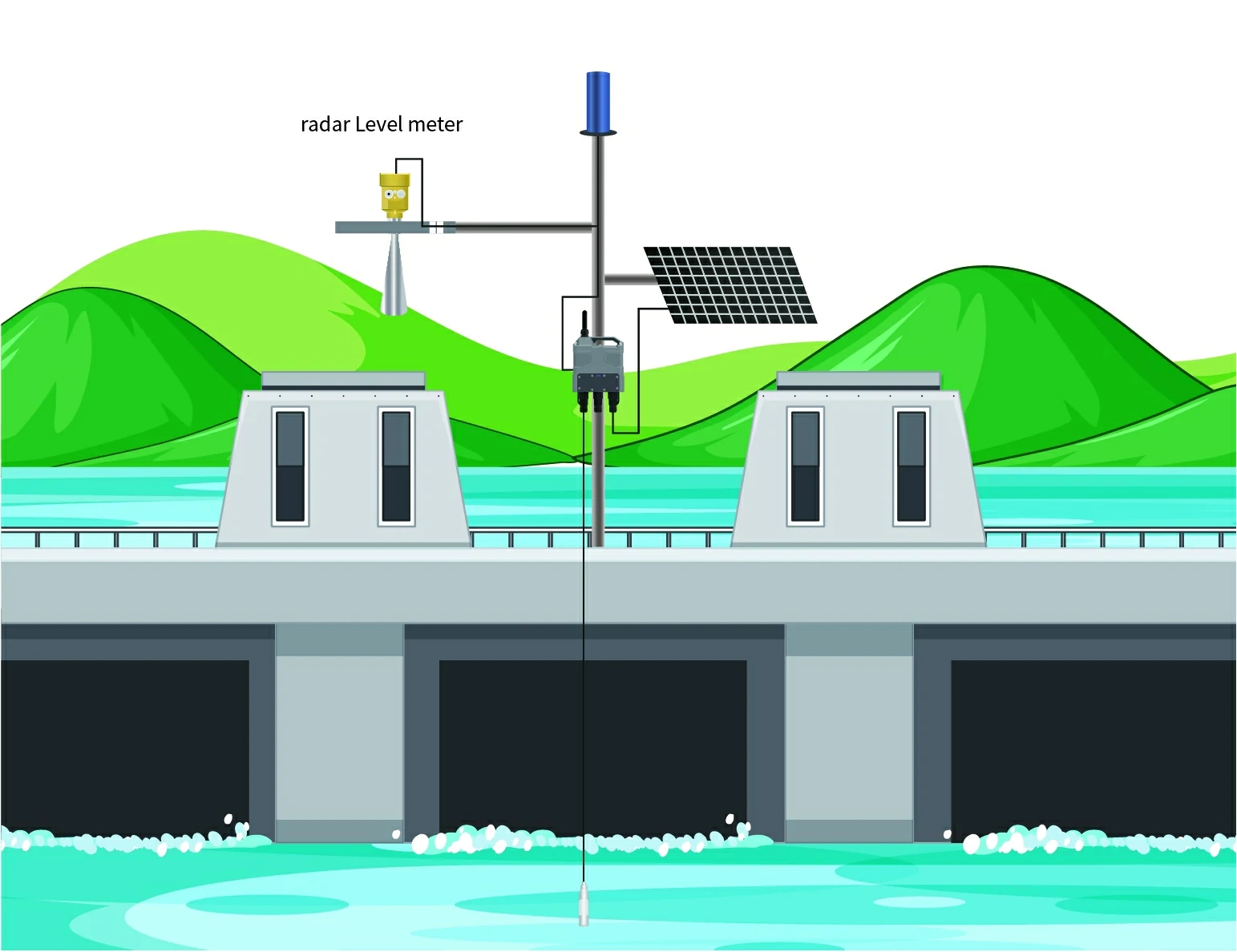

Real-time collection of reservoir water level, rainfall, and other information at dam monitoring points. Based on the changes in water level and the maximum capacity of the dam, calculations are made, and warnings and alarms are issued when the water level rises above the alert value.

more info...