17mm Submersible Level Transmitter

φ17mm

0m~10m…200mH2O

Measurement Accuracy: ±0.5%FS

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

LKZLD

Used For

Reservoirs, Dams, Coal Plants, Power Plants, Petrochemicals

Leave a MessageRadar Level Meter is used to measure the precise level of contaminated and corrosive media. Advanced microwave and Echo-tech processing technology ensure stable product performance. LKZLD is recommended for measuring solids and low dielectric constant media. It is also a safe choice for level measurement in small metallic and non-metallic containers. The radar level meter is easy to install and can be controlled remotely.

Feature

• Stable and accurate liquid and solid level measurement

• Small measurement blind area and strong concentration ability

• Ensure stable performance in complex environments

Specification

• Type: Low frequency radar, High frequency radar, Guided wave radar

• Model: LKZLD-A LKZLD-B LKZLD-C

• Measured Media: solid, liquid

• Measuring range: 0~75m

• Process connection: flange, thread flange, thread

• Media temp.: -40℃~ 250℃

• Process pressure: -0.1MPa~4.0MPa -

• Output signal: 4mA~20mA DC/HART(2-wire), RS485/Modbus(4-wire)

Image:

Radar Level Meter is used to measure the precise level of contaminated and corrosive media. Advanced microwave and Echo-tech processing technology ensure stable product performance. LKZLD is recommended for measuring solids and low dielectric constant media. It is also a safe choice for level measurement in small metallic and non-metallic containers. The radar level meter is easy to install and can be controlled remotely.

Feature

• Stable and accurate liquid and solid level measurement

• Small measurement blind area and strong concentration ability

• Ensure stable performance in complex environments

Specification

• Type: Low frequency radar, High frequency radar, Guided wave radar

• Model: LKZLD-A LKZLD-B LKZLD-C

• Measured Media: solid, liquid

• Measuring range: 0~75m

• Process connection: flange, thread flange, thread

• Media temp.: -40℃~ 250℃

• Process pressure: -0.1MPa~4.0MPa -

• Output signal: 4mA~20mA DC/HART(2-wire), RS485/Modbus(4-wire)

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

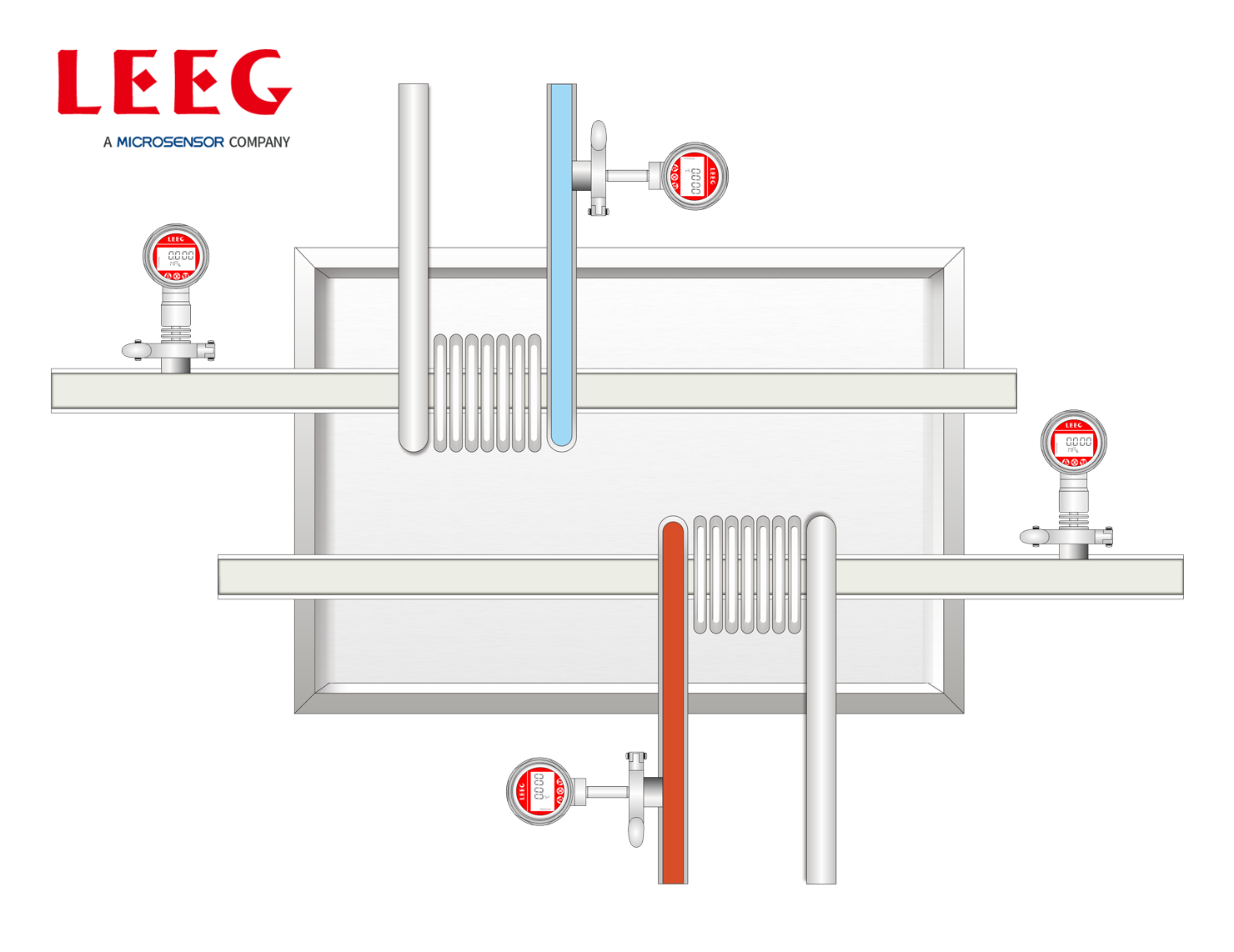

In beverage production and dairy processing, liquids are heated to specified temperatures through heat exchange, followed by rapid cooling to eradicate pathogens and prolong shelf life. Multiple stages such as heating and cooling of wort ensure that beer reaches the appropriate temperature for yeast cultivation. Both the cooler and preheater require monitoring of temperatures in the cooling and preheating tubes, as well as the pressure in the food pipelines.

more info...

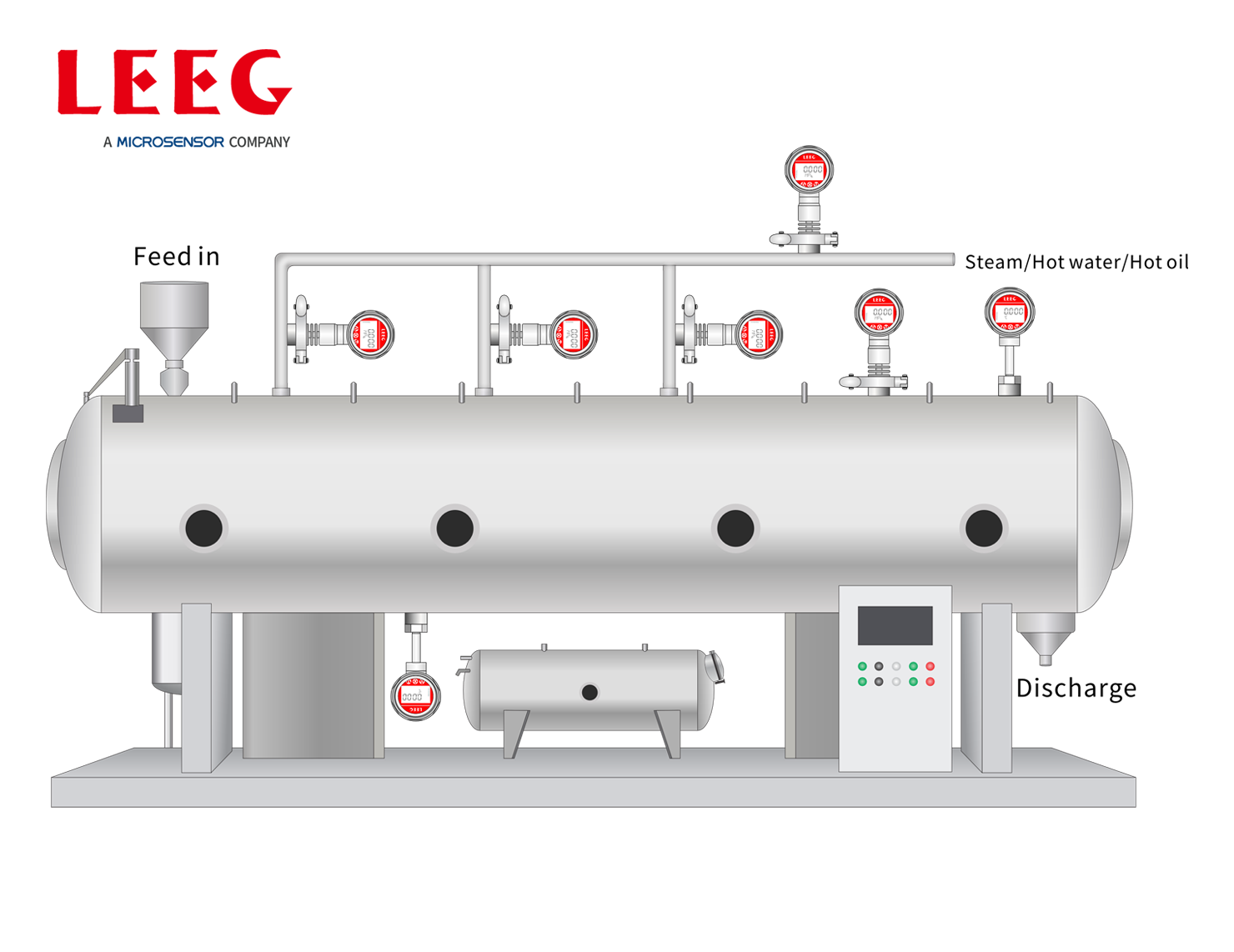

Dryers are often used to dry medicines or extract active ingredients from traditional Chinese medicines, which are easily decomposed in high temperature environments. Temperature measurement is required in the heating area, cooling area and material outlet of the dryer, and pressure transmitters are used to measure the pressure of air or gas to help adjust the air flow speed and fan operation status, or measure the pressure of steam, hot water, and hot oil pipelines.

more info...

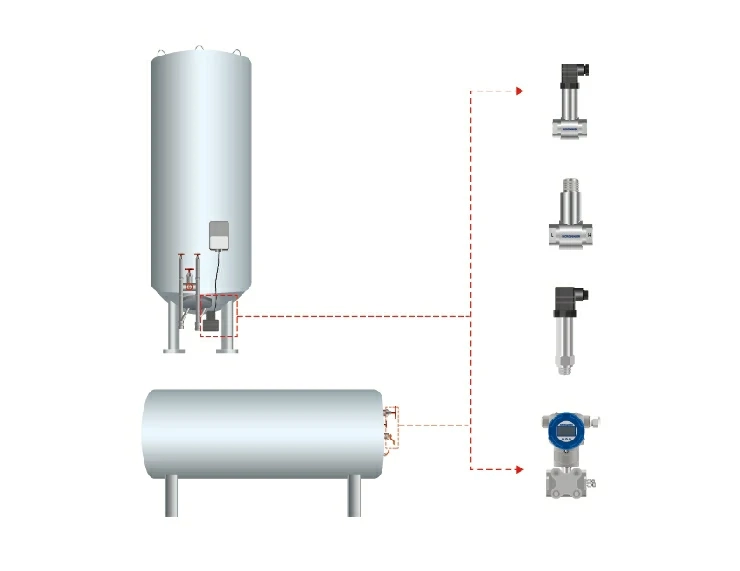

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

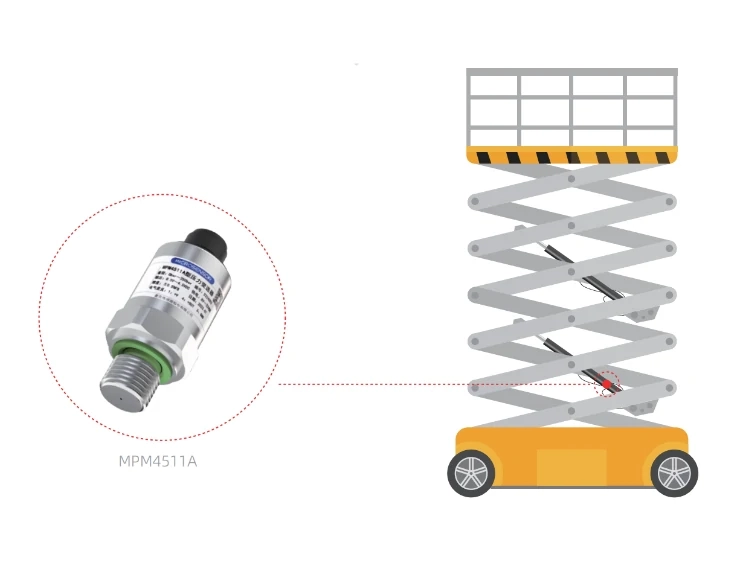

Aerial work platforms utilize hydraulic equipment for platform elevation to achieve high-altitude operations. In some fields, pressure transmitters are required to enable monitoring of operating conditions and fault diagnosis capabilities.

more info...