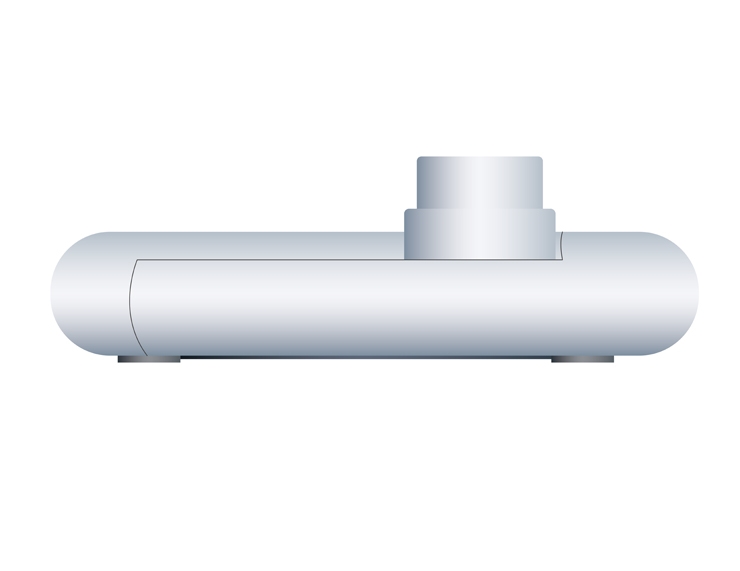

Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM489WZ4

Used For

Groundwater Monitoring, Power Plant, Urban Water Supply and Drainage, Hydrological Exploration

Leave a MessageCompared with the regular size, MPM489WZ4 is a 17mm Submersible Level Transmitter with a smaller diameter. MPM489WZ4 is based on the diffused silicon principle. All-in-one structure needn't an external adjustment. It is suitable for long-term use in liquids compatible with special vent cables and stainless steel housings. MPM489WZ4 is compact while performing stably.

Features

• Submersible design: The transmitter is designed to be completely submerged in liquid, making it ideal for tank level measurement.

• Wide Range: The transmitter is highly accurate, with a measurement range of up to 200m and an accuracy of ±0.5%FS.

• Robust construction: The transmitter is constructed from high-quality stainless steel, making it resistant to corrosion and able to withstand harsh environmental conditions.

Image:

Compared with the regular size, MPM489WZ4 is a 17mm Submersible Level Transmitter with a smaller diameter. MPM489WZ4 is based on the diffused silicon principle. All-in-one structure needn't an external adjustment. It is suitable for long-term use in liquids compatible with special vent cables and stainless steel housings. MPM489WZ4 is compact while performing stably.

Features

• Submersible design: The transmitter is designed to be completely submerged in liquid, making it ideal for tank level measurement.

• Wide Range: The transmitter is highly accurate, with a measurement range of up to 200m and an accuracy of ±0.5%FS.

• Robust construction: The transmitter is constructed from high-quality stainless steel, making it resistant to corrosion and able to withstand harsh environmental conditions.

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

more info...

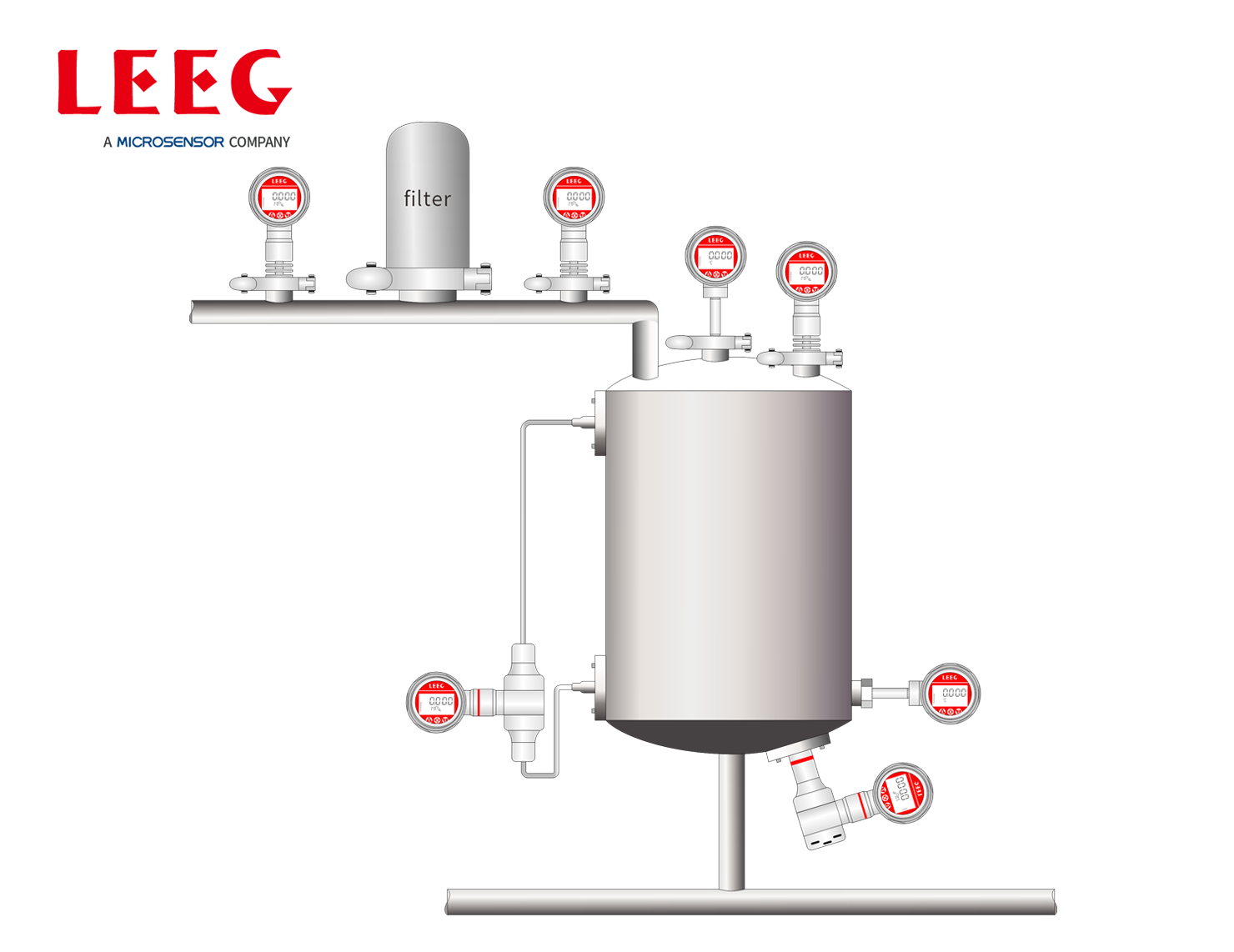

In the pharmaceutical industry, reaction kettles are mainly used to synthesize drugs and their active ingredients, as well as to prepare pharmaceutical intermediates. They are equipped with precise heating and cooling systems that can adjust the reaction temperature as needed to optimize the reaction rate and yield. Besides, the rc can maintain a stable pressure environment.

more info...

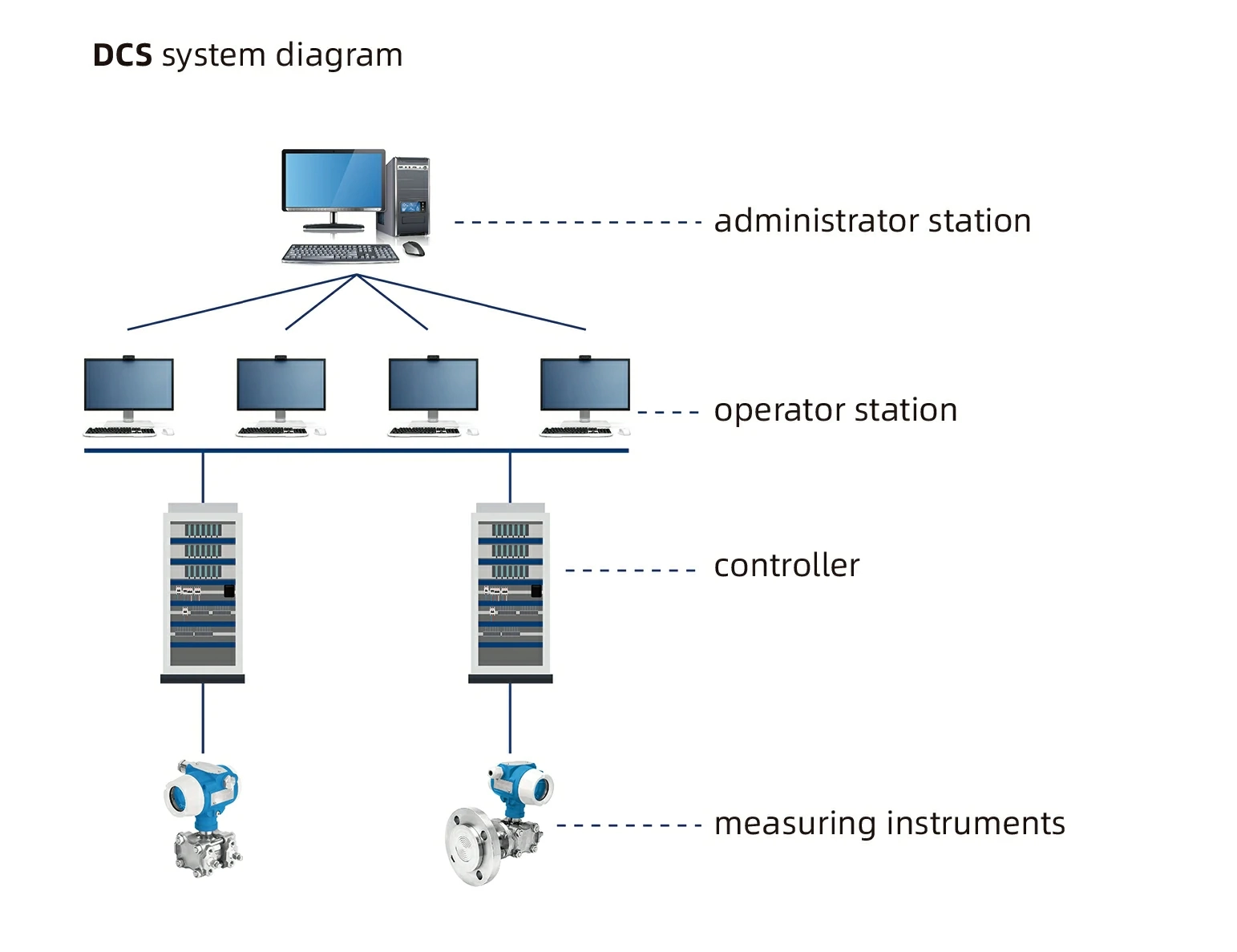

The papermaking process generates large amounts of pulp and chemicals, requiring the use of towers, pools, tanks, and other containers for storage and transportation. Installing intelligent pressure transmitters that can work in conjunction with computer control systems allows for timely monitoring of pressure, differential pressure, and flow information, effectively improving production efficiency and reducing losses.

more info...

Pressure transmitters, level transmitters, and mass flow meters are installed in fuel tanks to provide real-time monitoring of fuel levels and pressure. Users can track current location and fuel consumption, access historical vessel data, calculate voyage distance and total fuel usage, and analyze operational efficiency.

more info...