Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM426W Series

Used For

Fuel storage tanks like gasoline, diesel, kerosene. Chemical storage tanks like methanol, ethanol, lubricating oil, diesel exhaust fluid.

Leave a MessageMPM426W SERIES submersible level transmitter is designed for Fuel and Chemicals Measurement. MPM426W Series is a stable, accurate, real-time monitoring liquid level, pressure and temperature in storage tank multi-parameter measurement throw-in type liquid level meter. The measurement of fuels and chemicals requires the level meter to be resistant to aggressive media. The fully welded structure of the MPM426W Series ensures super tightness and medium compatibility.

MPM426W Series includes two models, MPM426WPC and MPM426WPF. MPM426WPC is mostly used in chemical liquid level monitoring scenarios. MPM426WPF is more suitable for fuel or oil level monitoring. These two products can also be widely used in applications requiring high corrosion resistance, explosion-proof performance, and protection performance, such as petroleum and petrochemical, vehicles, mining, and chemical industries. This fuel pressure transmitter provides an effective solution for tank level monitoring, control and overflow protection.

Features

• Special for fuel and chemicals measuring

• Support pressure, liquid level, temperature measurement

• Various output formats are optional

• Low power consumption, low maintenance cost

• CSA, IECEX, ATEX international explosion-proof certification

Image:

MPM426W SERIES submersible level transmitter is designed for Fuel and Chemicals Measurement. MPM426W Series is a stable, accurate, real-time monitoring liquid level, pressure and temperature in storage tank multi-parameter measurement throw-in type liquid level meter. The measurement of fuels and chemicals requires the level meter to be resistant to aggressive media. The fully welded structure of the MPM426W Series ensures super tightness and medium compatibility.

MPM426W Series includes two models, MPM426WPC and MPM426WPF. MPM426WPC is mostly used in chemical liquid level monitoring scenarios. MPM426WPF is more suitable for fuel or oil level monitoring. These two products can also be widely used in applications requiring high corrosion resistance, explosion-proof performance, and protection performance, such as petroleum and petrochemical, vehicles, mining, and chemical industries. This fuel pressure transmitter provides an effective solution for tank level monitoring, control and overflow protection.

Features

• Special for fuel and chemicals measuring

• Support pressure, liquid level, temperature measurement

• Various output formats are optional

• Low power consumption, low maintenance cost

• CSA, IECEX, ATEX international explosion-proof certification

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

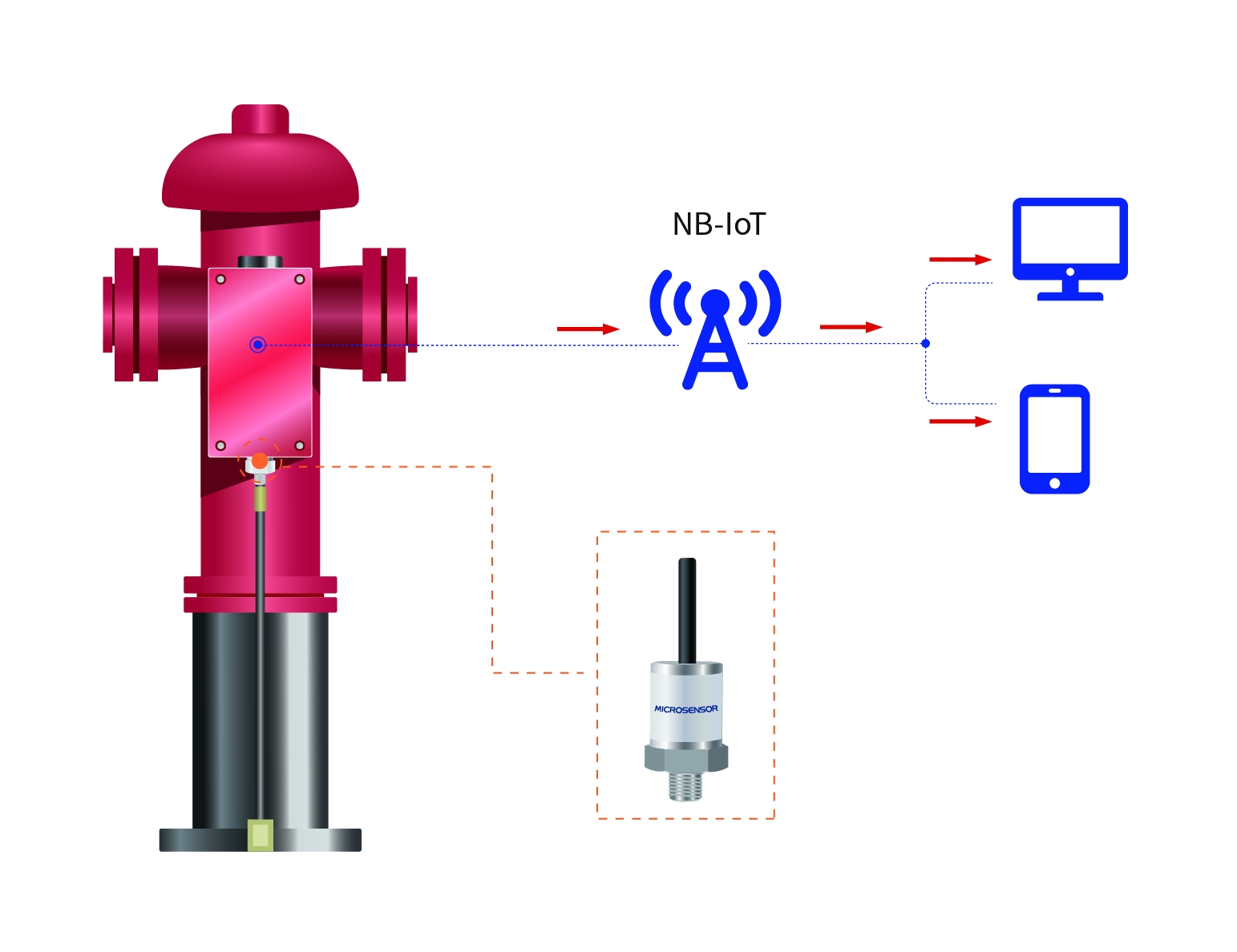

The micro-fused pressure transmitters can be used in hydrants to monitor the internal pressure of hydrants in real time, and send the data to the cloud platform for statistical analysis through wireless monitoring terminals and wireless networks. When an error occurs, it can locate the fault position and sends the alarm in time.

more info...

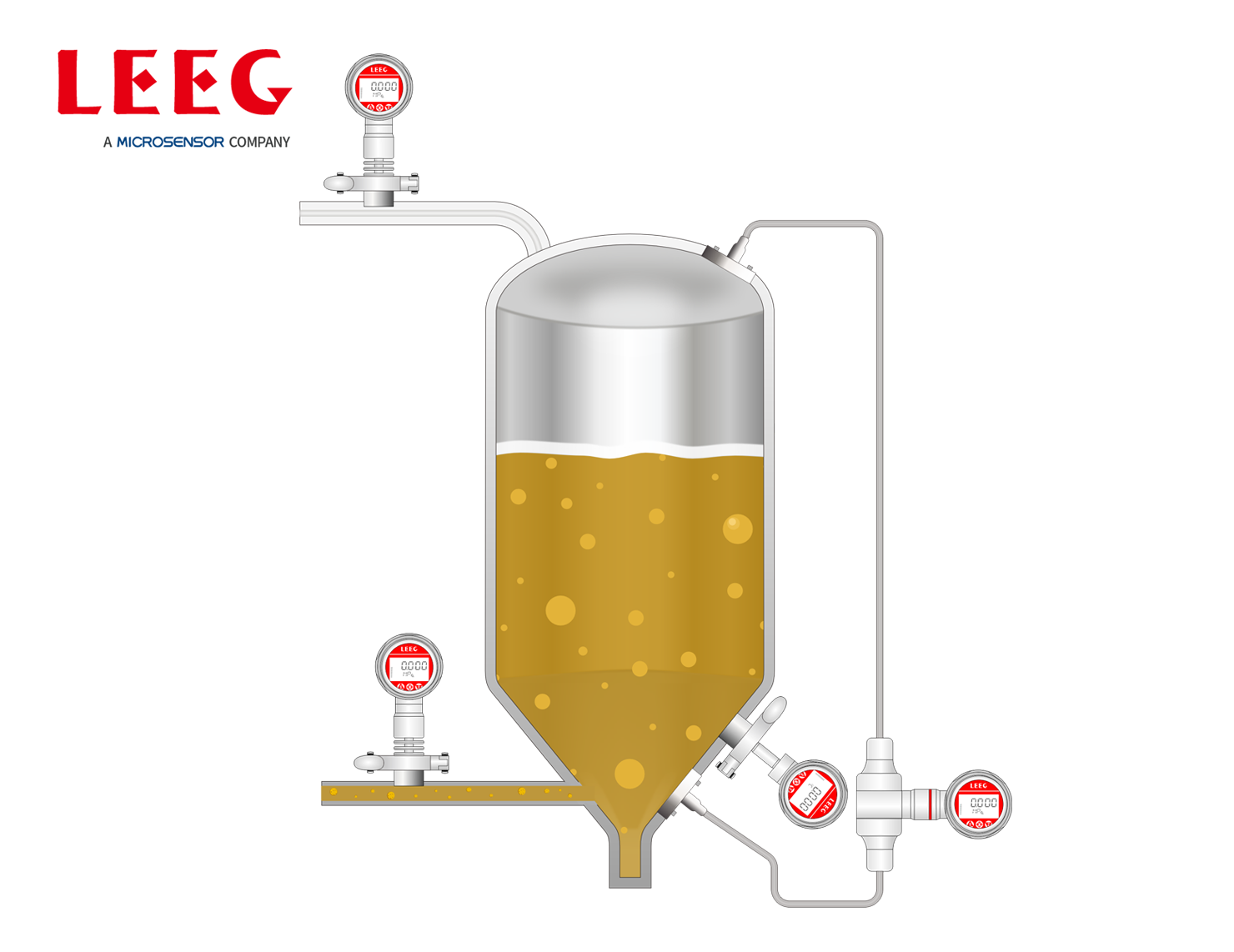

When the malt juice cools to the appropriate temperature, adding yeast initiates the fermentation process. During this process, yeast converts maltose dissolved in the malt juice into carbon dioxide and alcohol. To ensure a smooth fermentation process, it is necessary to measure the temperature and liquid level of the fermentation tank, as well as the carbon dioxide in the recovery pipe and the pressure in the yeast pipe.

more info...

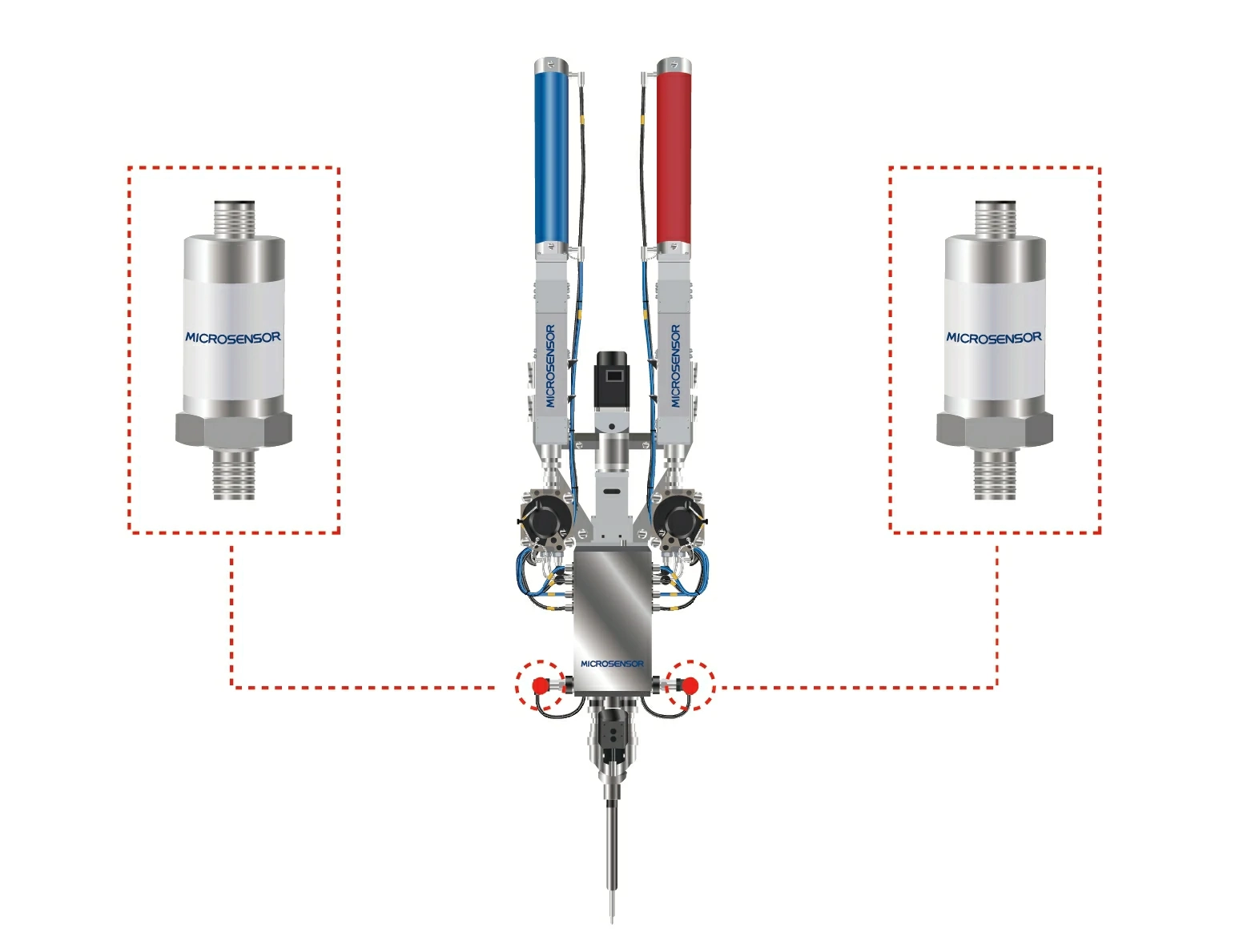

Dispensing machine is used to control adhesive, paint and other liquids. It requires compressed air to be fed into the glue bottle for proper operation. The role of the pressure transmitter is to monitor the pressure at the air inlet to ensure that the dispenser works properly.

more info...

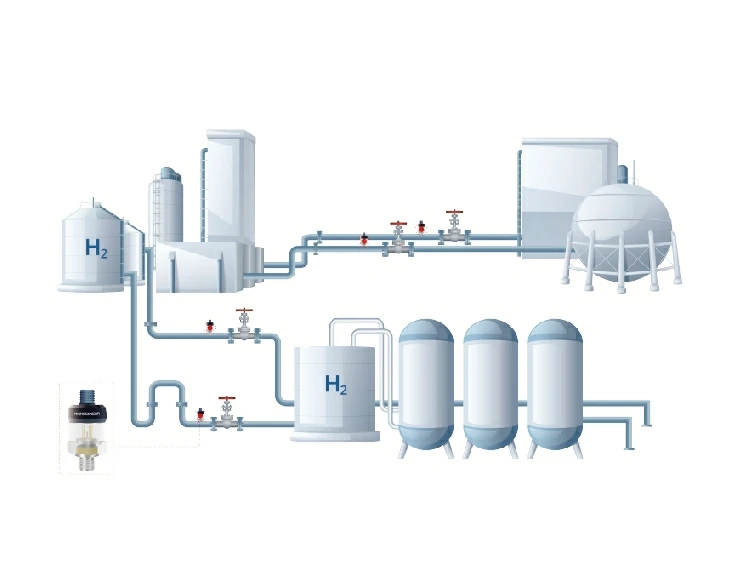

Due to the highly diffusive, flammable, and explosive characteristics of hydrogen, strict pressure monitoring by pressure transmitters is required to ensure its safety during transportation.

more info...