As an indispensable and important energy source for modern industrial society, oil extraction methods are continuously optimized along with technological progress. In the process of oil extraction, chemical treatment plays a key role in optimizing performance, reducing costs, and extending the life of oil and gas industrial facilities, infrastructure, and reservoirs. Correct chemical injection is critical to successfully reducing chemical and microbiological reactions, process and flow assurance issues, and improving production and operational efficiency.

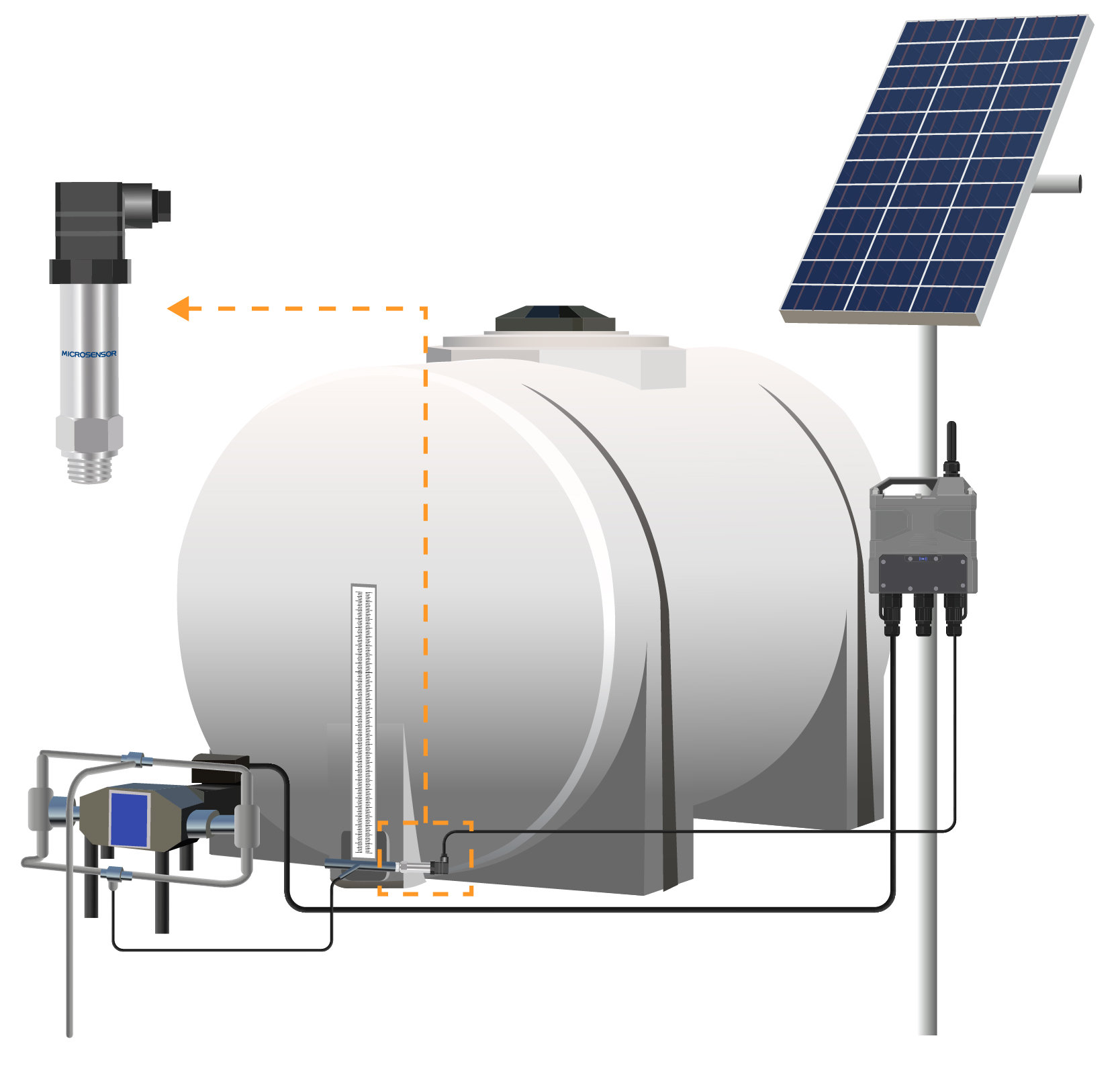

The flow monitoring of chemical injection and the remote monitoring of the liquid level of the storage tank provide practical solutions for the realization of digital oil fields. In terms of level monitoring of chemical storage tanks, Micro Sensor provides reliable corrosion-resistant pressure sensors with analog and digital outputs, and highly stable pressure sensors to ensure the continuous accurate level monitoring data and help the chemical injection system to quickly adjust its chemistry product dosage, reduce labor costs.

However, the current level monitoring of chemical storage tanks still has the following challenges:

Temperature Changes

Almost all sensors are susceptible to environmental temperature fluctuations, these fluctuations will affect the measured fluid, measuring process, or the sensing element itself, so the sensor itself needs to be temperature compensated.

Inclined/Inclined Water Tanks

When storage tanks are installed on the well site, they are rarely located on flat concrete pads. Instead, they sit on metal legs on uneven ground. This will cause the fuel tank to tilt to one side, making it difficult to know the real level.

Foaming

Chemicals that foam on the surface may cause difficulties in the measurement of the device.

Condensation

The accumulation of condensation on the equipment affects the accuracy of the sensor.

Chemical Compatibility

The sensor in direct contact with the medium needs to be made of a material compatible with the measured medium.

Based on the several difficulties in chemical storage tank level monitoring, Micro Sensor provides products with different measurement principles such as LR725 ultrasonic level gauge, MPM489 pressure transmitter and M20 pressure transmitter to deal with different working conditions on site, therefore the data can be accurately monitored.

MPM489 Pressure Transmitter

· Pressure range: -1bar~0bar to 0.1bar~1000bar

· Working temperature: -20℃~60℃ (explosion-proof type)

· Compensation temperature: 0℃~50℃

· A variety of wetted materials are available: SS316L, tantalum, titanium, and Hastelloy C

· A variety of analog output options: 4~20mA / 0.5~4.5V / 1~5V / 0~10V

· Widely applicable to fluid pressure in petroleum, chemical, electric power, hydrology, geology and other industries

· Explosion-proof products, reliable performance, safe and easy to use

· CE/RoHS/ATEX

Ultrasonic Level Meter

· Range: 0m, 2m, 4m, 6m, 8m, 12m, 15m, 20m (optional)

· Two-wire connection, strong sound wave emission, stable and reliable measurement

· Optional HART (version 7.0) output, downward compatibility

· Large display window with LCD, easy to debug and observe

· Overvoltage and overcurrent protection, lightning protection

· All plastic probe, acid and alkali resistance, adapt to harsh environments

Radar Level Meter

· Low frequency radar 6GHz: 0 ~ 35m, high frequency radar 26GHz: 0 ~ 70m, guided wave radar 500MHz-

1.8GHz: 0 ~ 30m

· Non-contact radar, nondestructive testing, environmentally friendly

· The antenna size is small, easy to install

· Reflectivity on inclined solid surfaces, enhanced with a shorter wavelength.

· Smaller measurement blind area, reliable measurement of small tank measurement

· Small beam angle, concentrated capacity, enhanced return capability and interference avoidance

· Highly resistant to corrosion and foam, unaffected

· Virtually unaffected by atmospheric changes such as water vapor, temperature, and pressure

· Electromagnetic wave operation remains unaffected by severe dust environments

· High signal-to-noise ratio, better performance in fluctuating conditions.

· Opt for high frequency for accurate measurements of solid and low dielectric medium

Not only that, Micro Sensor can also provide customized products and professional monitoring solutions according to the actual conditions of different projects. Don't hesitate to contact us via sales@microsensor.cn.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD