Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

M20

Used For

General Industry Measurement & Control, Pump & Compressor, Hydraulic Pressure & Pneumatic Device

Leave a MessageMicro Sensor M20 pressure transmitter is designed for general industry use which requires high accuracy, good reliability and stability. It is designed with precision, featuring a highly integrated electrical structure and full digital temperature compensation and calibration. M20 is certificated with international certifications under outstanding reliability like CE, RoHS, UL and REACH, etc. M20 4-20mA pressure sensor can measure mediums of air, water, mixed oil, or other fluid that can be compatible with wetted parts and tailor-made is available.

The pressure transmitter contributes to process optimization, quality control, and safety in manufacturing and automation, petrochemical and chemical processes, power generation, and the oil & gas industry.

Feature

• Small Size

• Measurement in general industrial occasions

• CE, RoHS, UL certifications

• Compatible with various media

• Flexible options meet specific application requirements

Image:

Micro Sensor M20 pressure transmitter is designed for general industry use which requires high accuracy, good reliability and stability. It is designed with precision, featuring a highly integrated electrical structure and full digital temperature compensation and calibration. M20 is certificated with international certifications under outstanding reliability like CE, RoHS, UL and REACH, etc. M20 4-20mA pressure sensor can measure mediums of air, water, mixed oil, or other fluid that can be compatible with wetted parts and tailor-made is available.

The pressure transmitter contributes to process optimization, quality control, and safety in manufacturing and automation, petrochemical and chemical processes, power generation, and the oil & gas industry.

Feature

• Small Size

• Measurement in general industrial occasions

• CE, RoHS, UL certifications

• Compatible with various media

• Flexible options meet specific application requirements

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

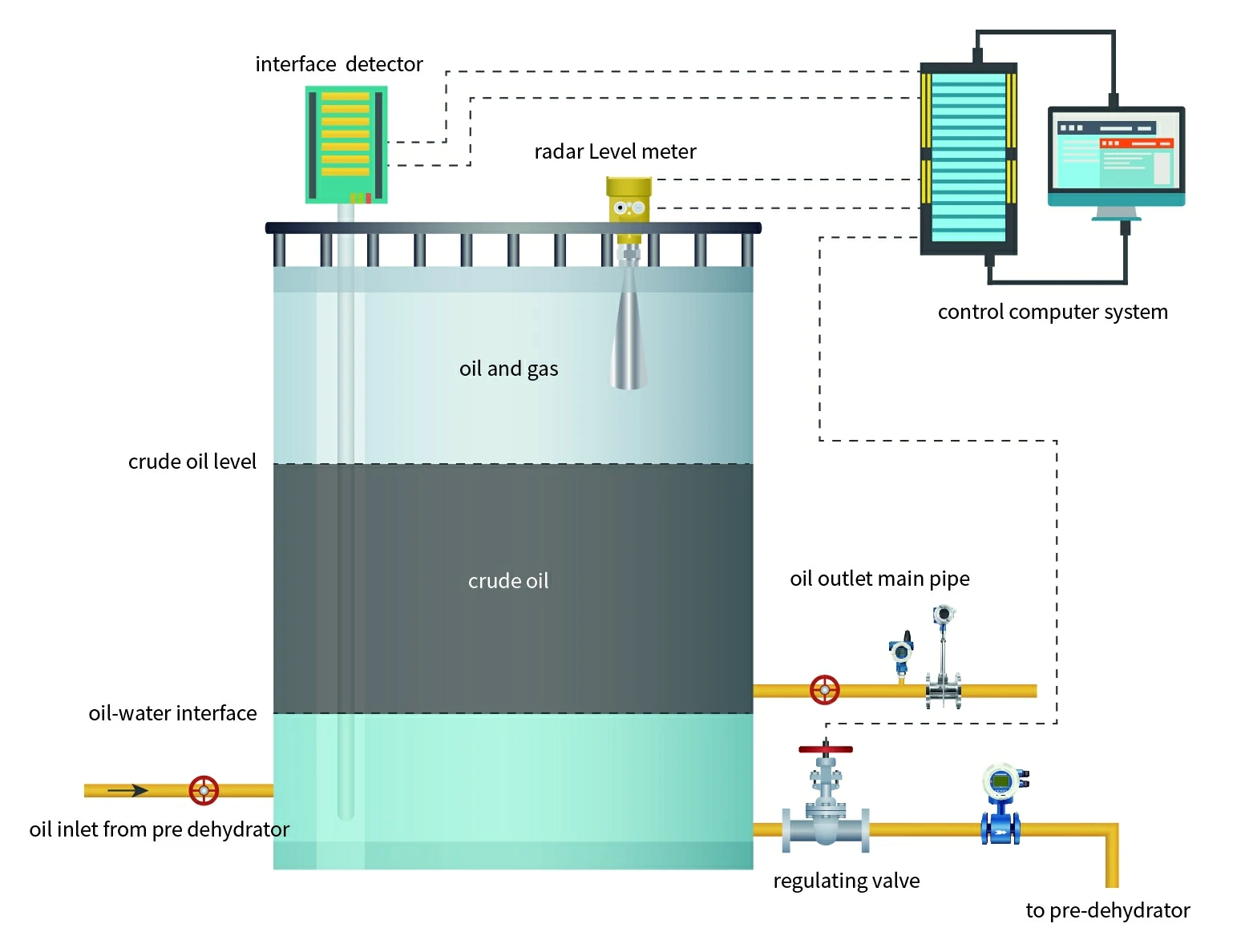

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...

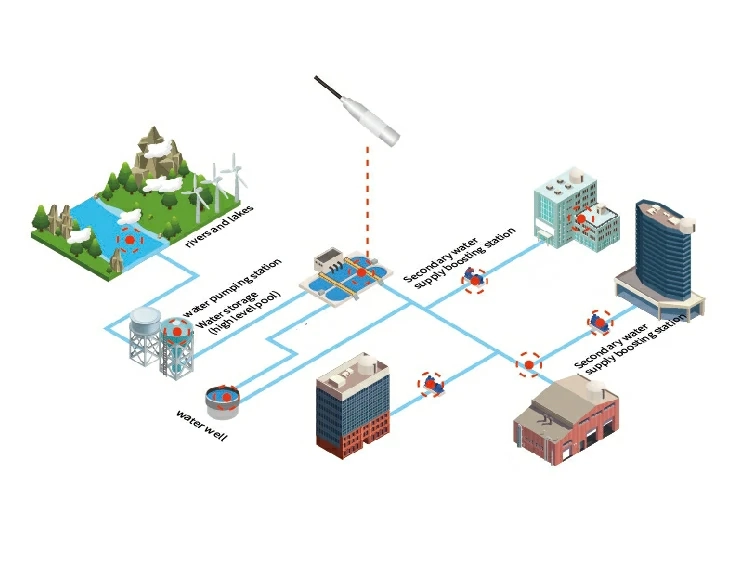

Monitoring the pressure, flow and other specifications of the entire pipe network by installing the monitoring device in water supply pipe network well contributes to scientifically scheduling water supply and ensuring the stable operation of the water supply system.

more info...

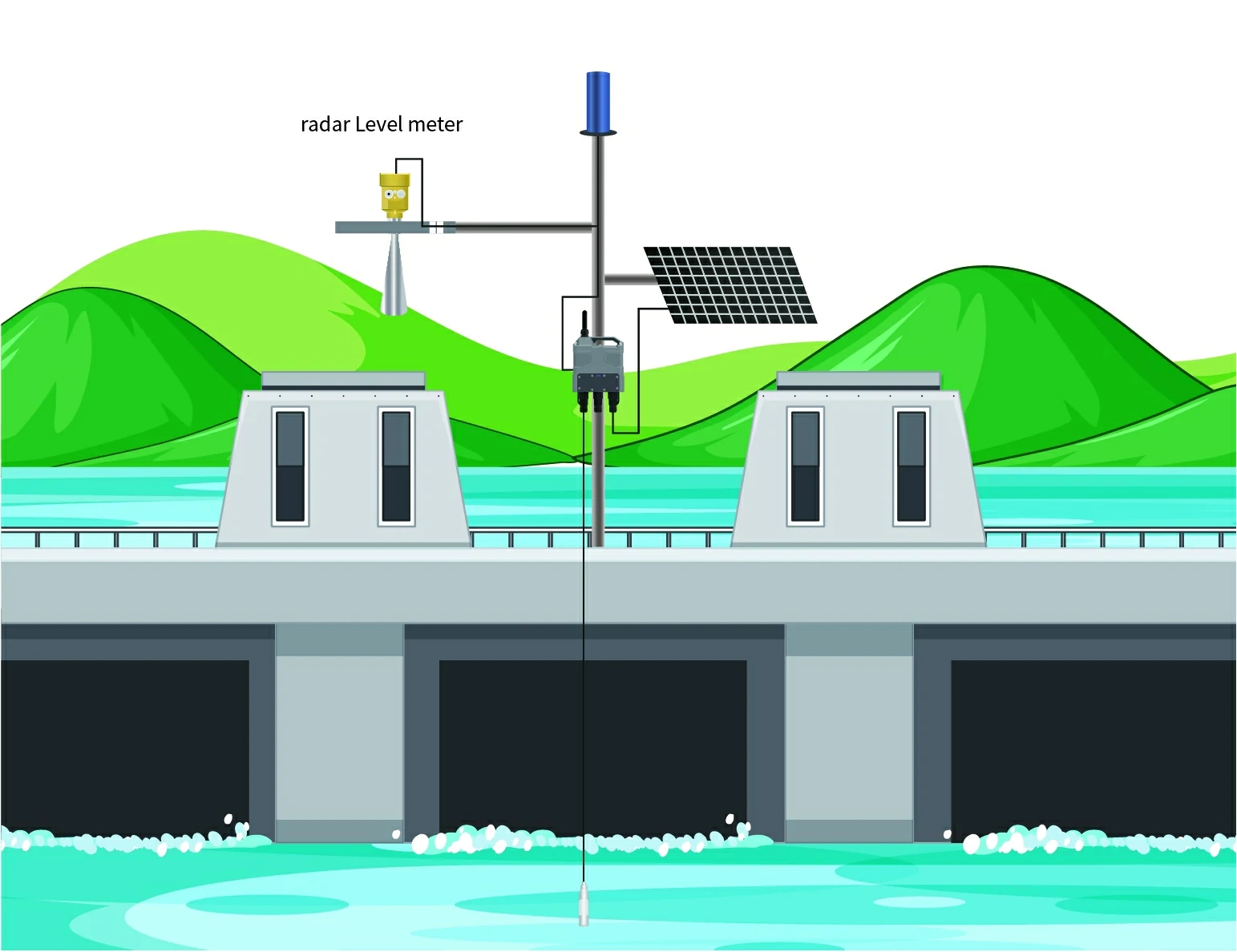

Real-time collection of reservoir water level, rainfall, and other information at dam monitoring points. Based on the changes in water level and the maximum capacity of the dam, calculations are made, and warnings and alarms are issued when the water level rises above the alert value.

more info...

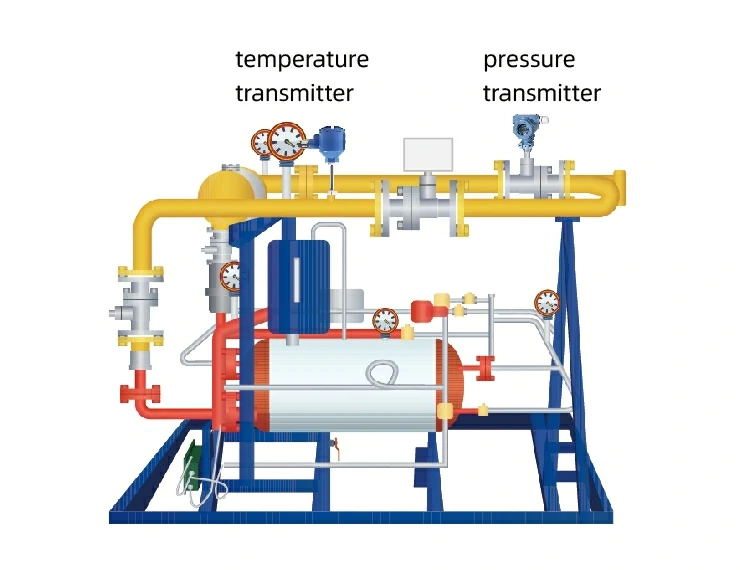

Gas skid equipment is a critical component in gas distribution systems. Equipped pressure and temperature transmitters can monitor parameters in real time. Then, the data is transmitted remotely to a central control room. The engineer or operator detects abnormal situations in time. It ensures the normal operation of the equipment and system.

more info...