Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4730

Used For

Hydrological Water Resources, Petroleum and Petrochemical Industry, Mechanical Engineering, Hydraulic and Pneumatic Control

Leave a MessageThe MPM4730 digital RS485 HART pressure transmitter utilizes piezoresistive technology and specially designed electronics to provide high accuracy of 0.1%FS in a temperature range of -30~80℃. It offers both analog and digital signal outputs, including 4~20mA, RS485-Modbus, and HART protocol. By incorporating digital temperature compensation, non-linearity correction techniques, and advanced production methods, the MPM4730 digital pressure sensor ensures stability, accuracy, and a wider pressure range. This compact, lightweight, intelligent pressure transmitter is ideal for precise measurement of flow pressure.

The pressure instrument is suitable for process control, water & waste treatment, chemical and mechanical equipment, offering versatile solutions.

Feature

• Pressure sensor with RS485 output interface or HART® protocol

• Capable of supporting network applications

• Certificated with CE, RoHS, CCS, and DNV

Specifications

• Range: -1bar…0mbar~100mbar…1000bar

• Accuracy: ±0.1%FS, ±0.25%FS, ±0.5%FS

• Overpressure: ≤2 times FS or 1100bar (minimum value is valid)

• Long-term Stability: ±0.2%FS/year

• Compensated Temperature: -10℃~70℃

• Application Temperature:

-30℃~80℃ (B1, B3)

-20℃~70℃ (B2, cable material: PE, PVC)

-20℃~80℃ (B2, cable material: PUR)

-20℃~60℃ (intrinsic safety type)

• Storage Temperature:

-40℃~85℃ (B1)

-20℃~85℃ (B2, B3)

Image:

The MPM4730 digital RS485 HART pressure transmitter utilizes piezoresistive technology and specially designed electronics to provide high accuracy of 0.1%FS in a temperature range of -30~80℃. It offers both analog and digital signal outputs, including 4~20mA, RS485-Modbus, and HART protocol. By incorporating digital temperature compensation, non-linearity correction techniques, and advanced production methods, the MPM4730 digital pressure sensor ensures stability, accuracy, and a wider pressure range. This compact, lightweight, intelligent pressure transmitter is ideal for precise measurement of flow pressure.

The pressure instrument is suitable for process control, water & waste treatment, chemical and mechanical equipment, offering versatile solutions.

Feature

• Pressure sensor with RS485 output interface or HART® protocol

• Capable of supporting network applications

• Certificated with CE, RoHS, CCS, and DNV

Specifications

• Range: -1bar…0mbar~100mbar…1000bar

• Accuracy: ±0.1%FS, ±0.25%FS, ±0.5%FS

• Overpressure: ≤2 times FS or 1100bar (minimum value is valid)

• Long-term Stability: ±0.2%FS/year

• Compensated Temperature: -10℃~70℃

• Application Temperature:

-30℃~80℃ (B1, B3)

-20℃~70℃ (B2, cable material: PE, PVC)

-20℃~80℃ (B2, cable material: PUR)

-20℃~60℃ (intrinsic safety type)

• Storage Temperature:

-40℃~85℃ (B1)

-20℃~85℃ (B2, B3)

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

Perfect coffee needs pressure. Water and steam pressure monitoring of the coffee machine ensures safe and high-quality coffee production. Accurately measuring pressure is required during the coffee bean extraction, hot water delivery, and cleaning of coffee machines.

more info...

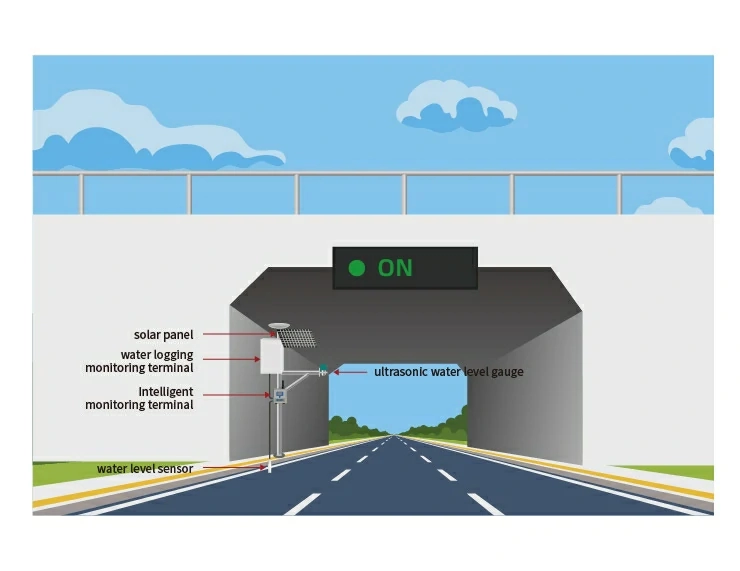

Real-time monitoring the low-ling areas, underpasses and bridge culverts. The current level and alarming messages are automatically displayed on the screen, such as “Passage”, “Allowing”, and “No entering”. The alarm will be triggered when the level is too high, aiming to ensure the personnel's safety.

more info...

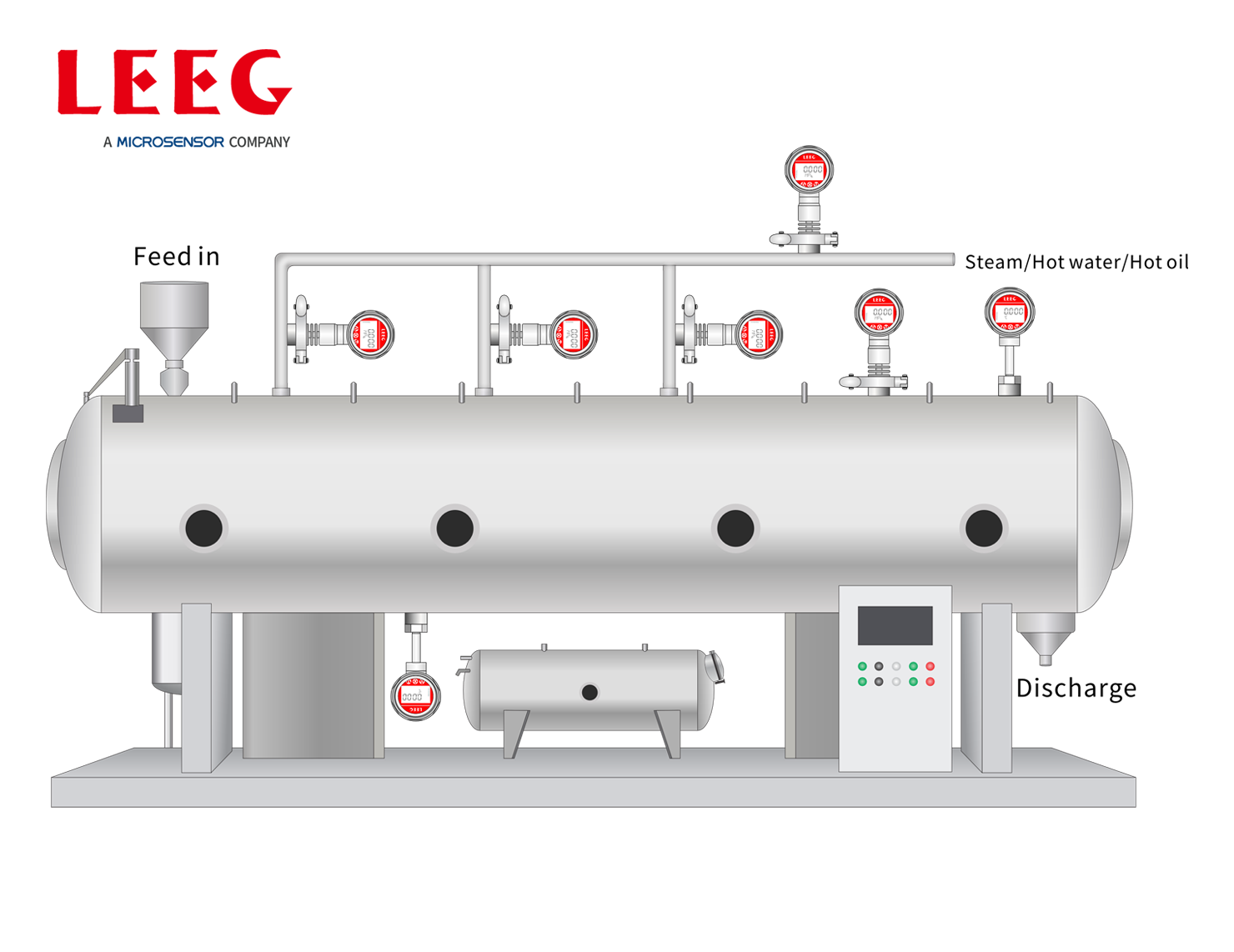

Dryers are often used to dry medicines or extract active ingredients from traditional Chinese medicines, which are easily decomposed in high temperature environments. Temperature measurement is required in the heating area, cooling area and material outlet of the dryer, and pressure transmitters are used to measure the pressure of air or gas to help adjust the air flow speed and fan operation status, or measure the pressure of steam, hot water, and hot oil pipelines.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...