New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

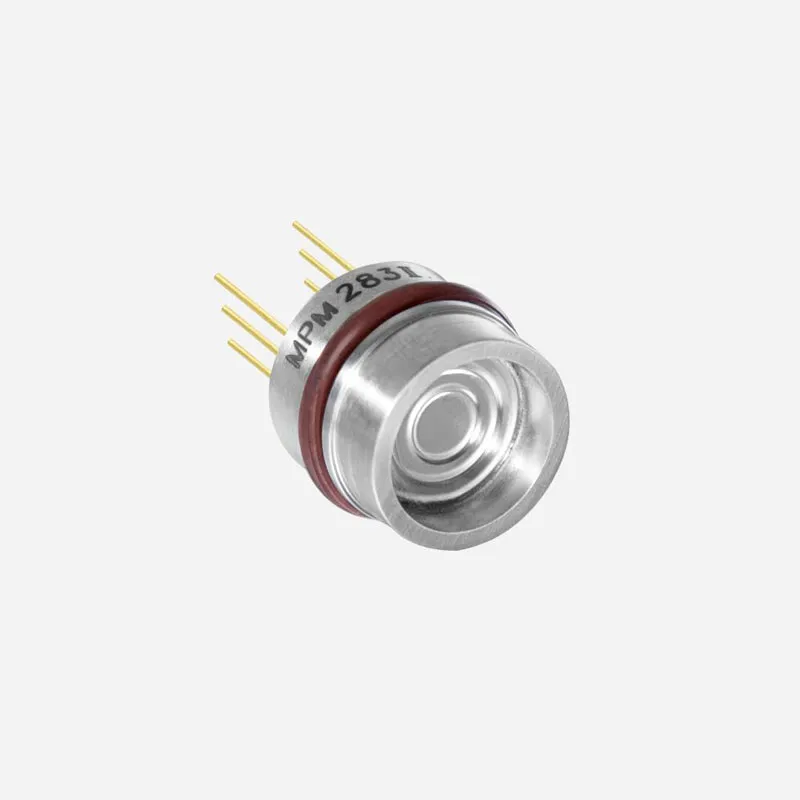

Basic Piezoresistive Pressure Sensors

Micro Sensors presents our piezoresistive pressure sensors, specifically designed for enhanced compatibility with liquid fluids pressure measurement. These fluid pressure sensors deliver a temperature-compensated, wide-range mV-output signal. With pressure ranges spanning from 70 to 1000 bar and from 1 to 1450 psi, our versatile membrane pressure sensors can be customized to meet unique material requirements, constructions, pressure port specifications

The feature of higher sensitivity, smaller temperature error, and better long-term stability makes pressure sensing element reliable and stable. The gold-plated diaphragm of MPM280Au is designed for hydrogen measurement. MPM281Pro is a high-accuracy, medium-isolated for high-demand pressure measurement. Digital I²C output MPM288DI measures pressure in conditions with strict power consumption requirements.

Small Size Pressure Sensors

Small size pressure sensors are ideal for applications with stringent dimensional requirements. The advantages of these pressure sensors include their small diameters and reduced heights, providing a compact size that saves space and meets the installation requirements of narrow spaces. Micro Sensor pressure sensors boast diameters ranging from Φ12.6mm to Φ19mm and heights as low as 6.5mm. Our compact-size mini pressure sensors are perfect for measuring the pressure of media compatible with stainless steel and Viton, particularly in working environments with limited installation space.

MPM283II allows easy integration into tight spaces or small devices with a wide measuring range of up to 1000 bar. Φ15mm oil-filled MPM285 is compatible with many media.

Anti-corrosive Pressure Sensors

Anti-corrosive pressure sensors are specifically designed for measuring pressure in corrosive liquids, fluids, and gases. Industries such as chemical processing, oil and gas, marine, and wastewater treatment often exposure to corrosive substances. Anti-corrosive pressure elements withstand a certain level of corrosive effects. With diaphragm materials such as Tantalum, Titanium, Hastelloy C, and stainless steel 316L, these sensors are well-suited for measuring pressure in challenging environments like seawater or corrosive media, including acid etching, stress corrosion, alkalis, chlorides, chlorine compounds, nitric acid, and sulfuric acid, among others.

Differential Pressure Sensors

Differential pressure elements typically consist of two pressure ports and two sensing elements that measure the pressure difference between the two ports. They are available in various configurations and are compatible with different media types, making them versatile for a broad range of applications. The differential pressure sensor ranges from 350 mbar to 35 bar. Featuring optional external resistors for temperature compensation and an all-welded structure, it is suitable for various fluid media. These water differential pressure sensors and differential air pressure sensors are widely used in industrial process control and other related fields for accurate differential pressure measurement.

What is a Pressure Seneor?

The elements or instruments measure the liquids or gas pressure. Pressure sensors convert the actual pressure into electronic signals that can be easily read. In addition to directly measuring pressure, these sensors can also infer other metrics such as the flow of fluids/gases, velocity, water levels, and even altitude. Known by a variety of names - including pressure transducers, pressure transmitters, pressure senders, pressure indicators, pressure gauges, and manometers - these versatile devices are integral to numerous sectors, from aerospace and healthcare to the petrochemical industry.

History of Pressure Sensor Development

The development of MEMS chips significantly influences the development of pressure sensors. It is essentially semiconductor sensors. C.S. Smith discovered the piezoresistive effect of silicon and germanium in 1954. This effect meant that when an external force is applied to a semiconductor material, its resistance would change significantly. Based on this principle, a strain resistor was glued to a metal film to convert the force signal into an electrical signal, thus enabling pressure measurement.

This marked the birth of piezoresistive pressure sensors. Subsequently, along with the development of silicon diffusion technology, each anisotropic corrosion technology, and micro-processing technology after the 1980s, gradually brought the pressure sensor to the micron level and the large-volume development stage.

Piezoresistive Pressure Sensors Working Principle

• Piezoresistive Effect

Piezoresistive pressure sensors operate based on the piezoresistive effect. When pressure is applied to the diaphragm, it deforms, causing mechanical strain in the piezoresistive elements. The strain leads to a change in the resistance of the piezoresistive elements. This change in resistance is proportional to the applied pressure.

• Wheatstone Bridge Configuration

Wheatstone bridge circuit measures the change in resistance. The Wheatstone bridge consists of four resistors, with the piezoresistive elements acting as two of the resistors. When pressure is applied, the resistance change in the piezoresistive elements unbalances the bridge circuit, inducing a voltage output proportional to the pressure.

• Signal Processing

The output voltage from the Wheatstone bridge is then processed by signal conditioning circuits. The amplified and converted signal can be displayed as pressure readings on a display or transmitted to a control system for further action.

How to Choose A Suitable Pressure Sensor?

Choosing a suitable pressure sensor requires determining the following factors:

• Pressure Type: Pressure type can be divided into gauge pressure (G), sealed gauge pressure (SG), absolute pressure (A), and differential pressure (D). The main difference is that different pressure points are used as reference points for the sensor's zero point. Application requirements and environmental conditions are important considered factors.

• Pressure Range: Make sure the pressure range provided covers the pressures likely to occur in the working application. It's suggested that the normal working pressure should be near the middle of the selected measurement range. On the one hand, this can maximize accuracy and reduce errors. On the other hand, possible accidental pressure changes will not cause the sensing element to be overloaded and damaged.

• Size: The installation environment determines the size of pressure elements, such pipes diameter, equipment size, etc. If you cannot determine the size of the installation space, it will cause installation problems for the pressure element. Micro Sensor provides ф19mm, ф17mm, ф15mm, ф12.6mm and other optional diameters. The height is also optional for different applications, such as 6.5mm and 11.5mm. Customized sizes are also available upon customer request.

• Operating Temperature: The working temperature range refers to the pressure sensor that can work without failure at a certain temperature. Some pressure elements' operating temperature range can reach -40~125℃.

• Special Working Conditions: Special working conditions are mainly the requirements of the installation environment. If there are factors such as high temperature, high pressure, corrosive media in the environment, you need to choose a pressure sensor with corresponding materials and protective measures. According to special working conditions, Micro Sensor will analyze the actual needs of customers and provide the most suitable customized product solutions.

Production Processes of Pressure Sensors

The main production processes of a pressure sensor are gluing, binding, diaphragm welding, oil filling, sealing, pressure impact, aging, temperature compensation, resistance adjustment, and inspection.

The quality of sensors is not only influenced by their properties, but also by their production process. The R&D and manufacturing of industrial pressure sensors of Micro Sensor is originally from the 1970s, with our production line showing the development of China's sensor technology. Over the years, the production line has been expanded and upgraded several times, representing the great progress of the industry.

At present, Micro Sensor has its advanced manufacturing site, realizing digitization, automation, and flexibility, and manufacturing series star products, including customized MPM280 Series, high-performance MPM281 Series, and general MPM288 Series, which conform to the highest quality criteria to meet the client's satisfaction.

Advantages of MICROSENSOR Piezoresistive Pressure Sensor

• Automation Manufacturing Equipment

The fully automatic production process better ensures comprehensive performance. The automated production line ensures stability and consistency and meets customers' order needs in different batches. Micro Sensor uses advanced automatic production equipment in key processes such as bonding, diaphragm welding, oil filling, sealing, and compensation.

• Mature Production Technology

The level of manufacturing technology has a crucial impact on product performance. As a pressure sensor manufacturer with decades of production experience, Micro Sensor ensures the accuracy and reliability of pressure elements through the following process technologies:

1. Pressure Cycling and Aging: The two processes mainly solve the product's long-term stability problem. All products are aged and tested through a simulated pressure and temperature environment.

2. Automatic Compensation Test System: Temperature compensation mainly solves the temperature drift of the silicon chip. Compensation testing reduces or offsets the drift in the output signal of a piezoresistive pressure sensor as a function of temperature. It confirms whether product meets performance indicators. All pressure sensors implement output performance testing by multi-temperature point under advanced testing equipment and systems.

3. Laser Trimming: The laser cutting process trims the resistance value to the preset value. Precise etching compensates for the resistance of the corresponding resistor on the ceramic plate. This makes it consistent within the error range with the resistance value provided by the compensation test.

• Advanced Products

1. Higher Sensitivity

Sensitivity can express the degree of amplification of the input signal by the sensor in practical applications. The piezoresistive pressure sensor can be more sensitive and accurate when detecting small changes in pressure. Micro Sensor's higher sensitivity pressure sensor provides more reliable and stable measurement.

2. Smaller Temperature Error

Silicon piezoresistive pressure sensors are temperature-sensitive. At present, Micro Sensor's silicon piezoresistive sensors have fully adopted laser trimming technology and related algorithms. A dedicated processing chip or application circuit performs temperature compensation under software operation. This allows silicon piezoresistive sensors to achieve smaller temperature errors and better stability.

3. Better Long-Term Stability

The main factors affecting long-term stability are its structure, manufacturing process, and environmental adaptability. Micro Sensor's sensors undergo pressure and fatigue tests in strict accordance with process requirements during the production process. The output values of the tested sensors are essentially unaffected even by changes in external temperature and pressure.

4. Customized Configuration Options

Micro Sensor offers customization options for pressure type, measurement range, materials, diameter size, etc. Customized pressure elements allow customers to tailor specifications to suit specific application requirements.

Resources

-

Reliable Measurement Solutions for Marine VOCs Monitoring

As IMO emission regulations continue to tighten, VOC control has become a standard requirement in marine environmental protection systems. Ensuring safe, stable, and compliant operation of VOC treatment units—such as RTO systems, adso...

-

Electromagnetic Flowmeters in Plumbing Flow Test Benches

Flow testing is a fundamental and critical step in the factory inspection of plumbing products, including faucets, angle valves, mixing valves, and fittings. Accurate and repeatable flow measurements directly impact product performance...

-

MDM7000 Series Pressure Transmitters Obtain IECEx Flameproof Certification

In industries such as oil and gas, chemical processing, LNG, and marine engineering, pressure instrumentation must deliver not only accurate measurement but also proven safety and long-term stability in demanding and potentially explos...

-

Micro Sensor Concludes Its 8th Technology Conference

As digitalization and intelligent manufacturing continue to advance, technical capabilities have become a key driver of long-term growth in the measurement and control industry. In 2025, Micro Sensor held its 8th Technology Conference,...

-

Pressure, Flow, and Temperature Solutions for Straw-to-Sugar Production

Driven by China’s “dual-carbon” strategy and the growing circular economy, straw-based sugar production has emerged as a key pathway for turning agricultural residues into valuable resources. By converting crop straw into sugar solu...

-

MDM7000 Series Pressure Transmitters: ATEX-Certified for Hazardous Areas

In hazardous areas, instrumentation is a critical part of the safety chain. In oil & gas, chemical, and storage & transport industries, pressure measurement instruments must operate reliably under high temperatures, high pressures, and...

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD