Piezoresistive Pressure Sensor

Φ19x11.5mm

0bar~0.35bar…1000bar

Constant Voltage Supply

MPM281Pro

Used For

Medical Instruments, Indusrial Process Control, Air Refrigeration or Compressors, Pressure Transmitters, Hydraulic System and Switch

Leave a MessageMPM281Pro is a medium isolation pressure sensor with high accuracy. It uses a highly stable diffusion silicon chip and is housed in a 316L stainless steel structure with a diameter of Ф19mm. This product is also equipped with an external laser trimming compensation board, which can accurate adjust the temperature error and zero output. Besides, the gain resistance can be fine-tuned to achieve a ne tFS output signal of 3.012V ±1%.

The product is widely used in applications where pressure measurement is critical. As a vacuum pressure sensor, it enhances the accurate monitoring in the field of vacuum measurement. In these applications, it is able to deliver excellent performance and stability to meet the high demands of customers. Click here to get more types of pressure sensors.

Features

• Measurement range: 0bar~0.07bar…35bar

• Nonlinearity: ±0.1%FS

• Gauge, Absolute

• Constant current power supply

• Wide compensated temperature range of -20℃ ~85℃

• Long-term stability: ± 0.1%FS/Year

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: Gray Ribbon with plug(UL2651-6P,26AWG,2451HM-6P)

• Common mode voltage output: 50% input (typ.)

• Input impedance: 2kΩ ~ 8kΩ

• Output impedance: 3kΩ ~ 6kΩ

• Response time (10%~90%): <1ms

• Insulation resistance: 100MΩ@100V DC

• Overload: 2 times FS or 1100bar(min. value is valid)

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Vent tube: Stainless steel 316L

• Outline: Ribbon cable

• O-ring: EPDM (ethylene propylene diene monomer)

• Net weight: Approx 16g

Image:

MPM281Pro is a medium isolation pressure sensor with high accuracy. It uses a highly stable diffusion silicon chip and is housed in a 316L stainless steel structure with a diameter of Ф19mm. This product is also equipped with an external laser trimming compensation board, which can accurate adjust the temperature error and zero output. Besides, the gain resistance can be fine-tuned to achieve a ne tFS output signal of 3.012V ±1%.

The product is widely used in applications where pressure measurement is critical. As a vacuum pressure sensor, it enhances the accurate monitoring in the field of vacuum measurement. In these applications, it is able to deliver excellent performance and stability to meet the high demands of customers. Click here to get more types of pressure sensors.

Features

• Measurement range: 0bar~0.07bar…35bar

• Nonlinearity: ±0.1%FS

• Gauge, Absolute

• Constant current power supply

• Wide compensated temperature range of -20℃ ~85℃

• Long-term stability: ± 0.1%FS/Year

Electrical Performance

• Power supply: ≤2.0mA DC

• Electrical connection: Gray Ribbon with plug(UL2651-6P,26AWG,2451HM-6P)

• Common mode voltage output: 50% input (typ.)

• Input impedance: 2kΩ ~ 8kΩ

• Output impedance: 3kΩ ~ 6kΩ

• Response time (10%~90%): <1ms

• Insulation resistance: 100MΩ@100V DC

• Overload: 2 times FS or 1100bar(min. value is valid)

Construction Performance

• Diaphragm: Stainless steel 316L

• Housing: Stainless steel 316L

• Vent tube: Stainless steel 316L

• Outline: Ribbon cable

• O-ring: EPDM (ethylene propylene diene monomer)

• Net weight: Approx 16g

Range: -1bar…-0.35bar ~ 0bar ~0.35bar…700bar

No need for re-calibration for users, high precision

Customizable dimensions

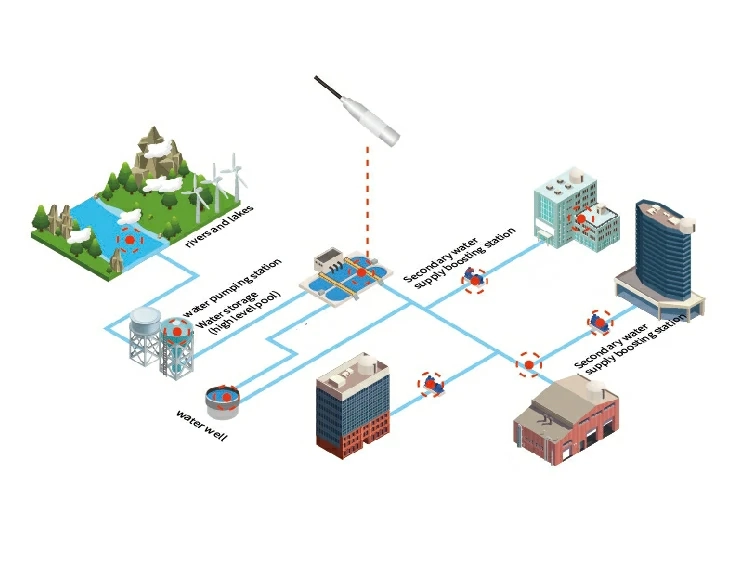

Monitoring the pressure, flow and other specifications of the entire pipe network by installing the monitoring device in water supply pipe network well contributes to scientifically scheduling water supply and ensuring the stable operation of the water supply system.

more info...

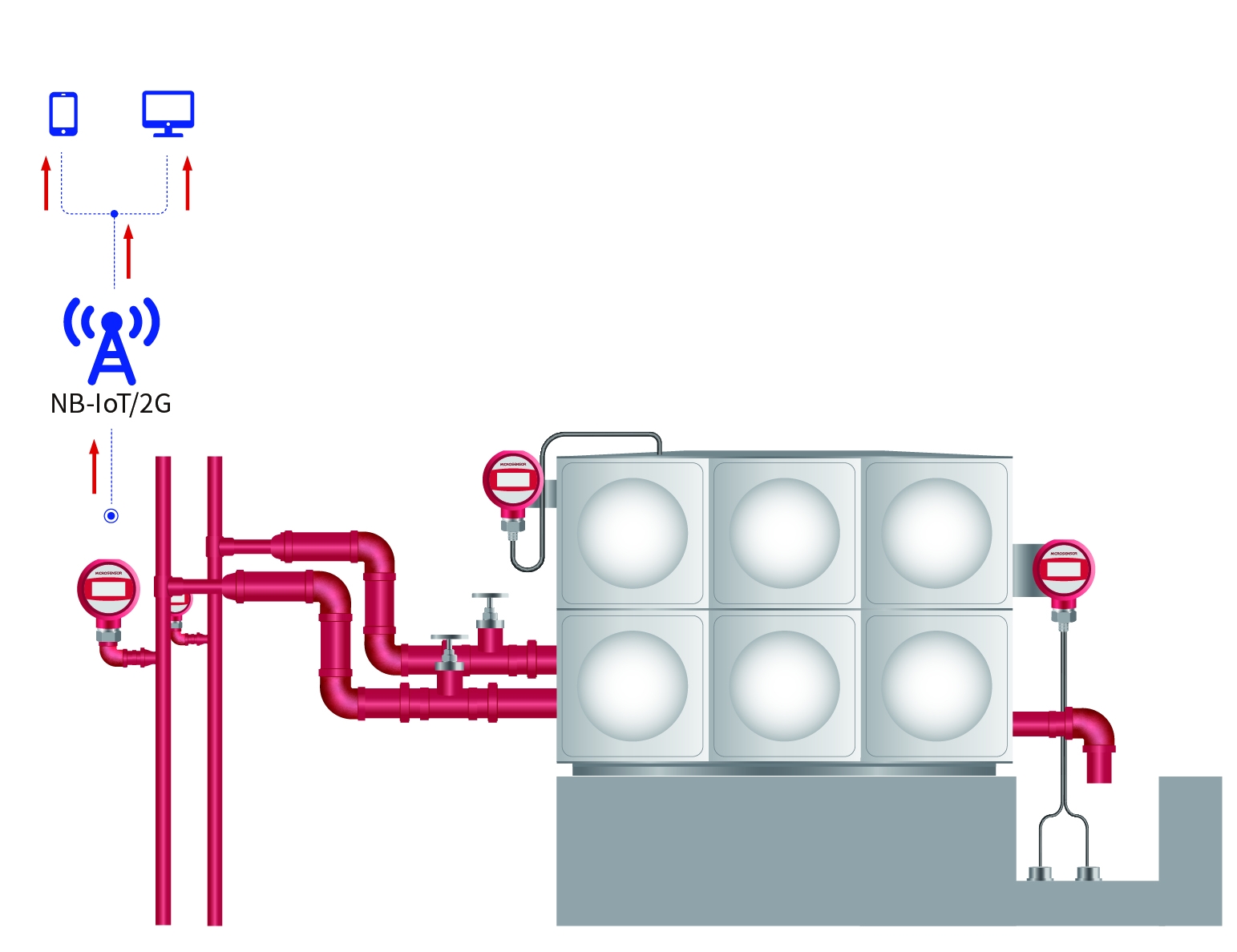

The normal operation of fire-fighting water pipeline plays an important role in safeguarding citizens' personal and property safety. Monitoring instruments are installed at each monitoring point of the fire protection pipeline to monitor pressure and level data in real time, so that when an error occurs, faults are located in time and alarms are given to facilitate staff maintenance and processing.

more info...

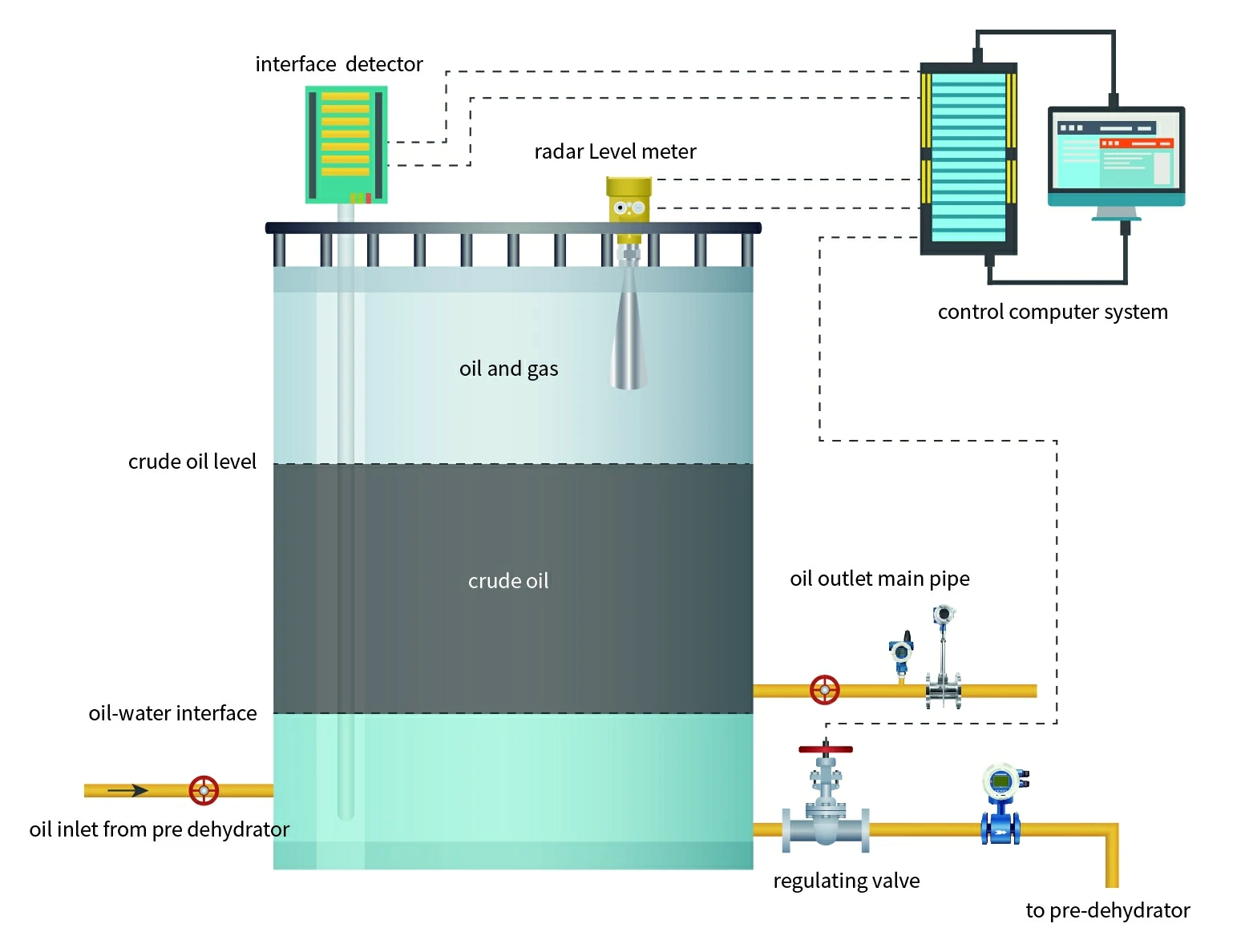

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...

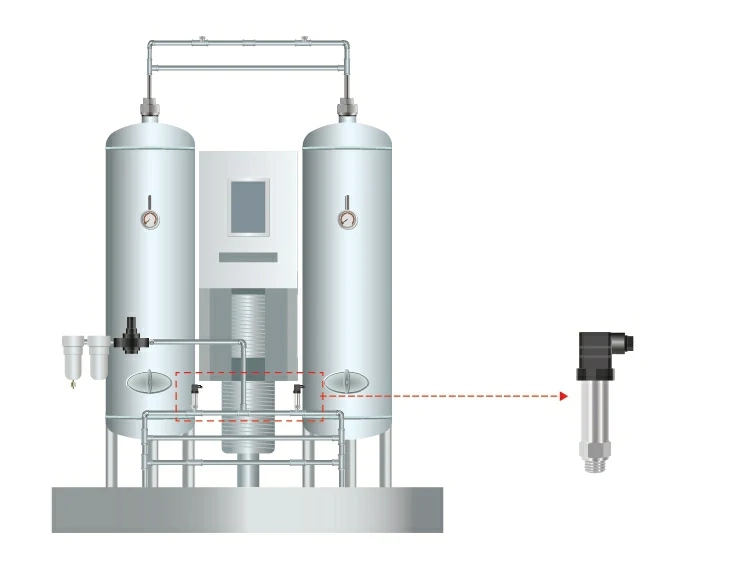

Nitrogen/oxygen generators are widely utilized in electronic equipment, medical devices, air conditioning refrigeration, and food & beverage industries. Pressure transmitters, being vital components of nitrogen/oxygen generators. They monitor the pressure within the container and throughout the variable pressure adsorption process.

more info...