High Pressure Range Pressure Sensor

Φ16.8x12mm

0bar~2bar…1000bar

-10~80℃ Compensated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM281PT

Used For

Industrial Process Control, Hydraulic System and Switches, Refrigeration Equipment and Air Conditioning Systems, Medical Oxygen Pressure Measurement

Leave a MessageMPM281PT pressure and temperature sensor is a sensitive element for integrated pressure and temperature measurement. The highly reliable diffused silicon pressure-sensitive chip and PT100 temperature measuring element meet the needs of various industrial occasions. The consistency of each batch of products under strict pressure and temperature characteristic test. The long-term temperature stability error of the atmospheric pressure sensor is ≤0.05%/year and the temperature accuracy can reach ±0.5°C. The integration of temperature & pressure can be applied in many scenarios, such as industrial process control, oil and gas transportation monitoring, etc.

Features

• Temperature and pressure integration

• Stainless steel 316L shell, diameter Ф19mm

• Highly integrated structure

• High stability and high precision imported diffused silicon chip

Image:

MPM281PT pressure and temperature sensor is a sensitive element for integrated pressure and temperature measurement. The highly reliable diffused silicon pressure-sensitive chip and PT100 temperature measuring element meet the needs of various industrial occasions. The consistency of each batch of products under strict pressure and temperature characteristic test. The long-term temperature stability error of the atmospheric pressure sensor is ≤0.05%/year and the temperature accuracy can reach ±0.5°C. The integration of temperature & pressure can be applied in many scenarios, such as industrial process control, oil and gas transportation monitoring, etc.

Features

• Temperature and pressure integration

• Stainless steel 316L shell, diameter Ф19mm

• Highly integrated structure

• High stability and high precision imported diffused silicon chip

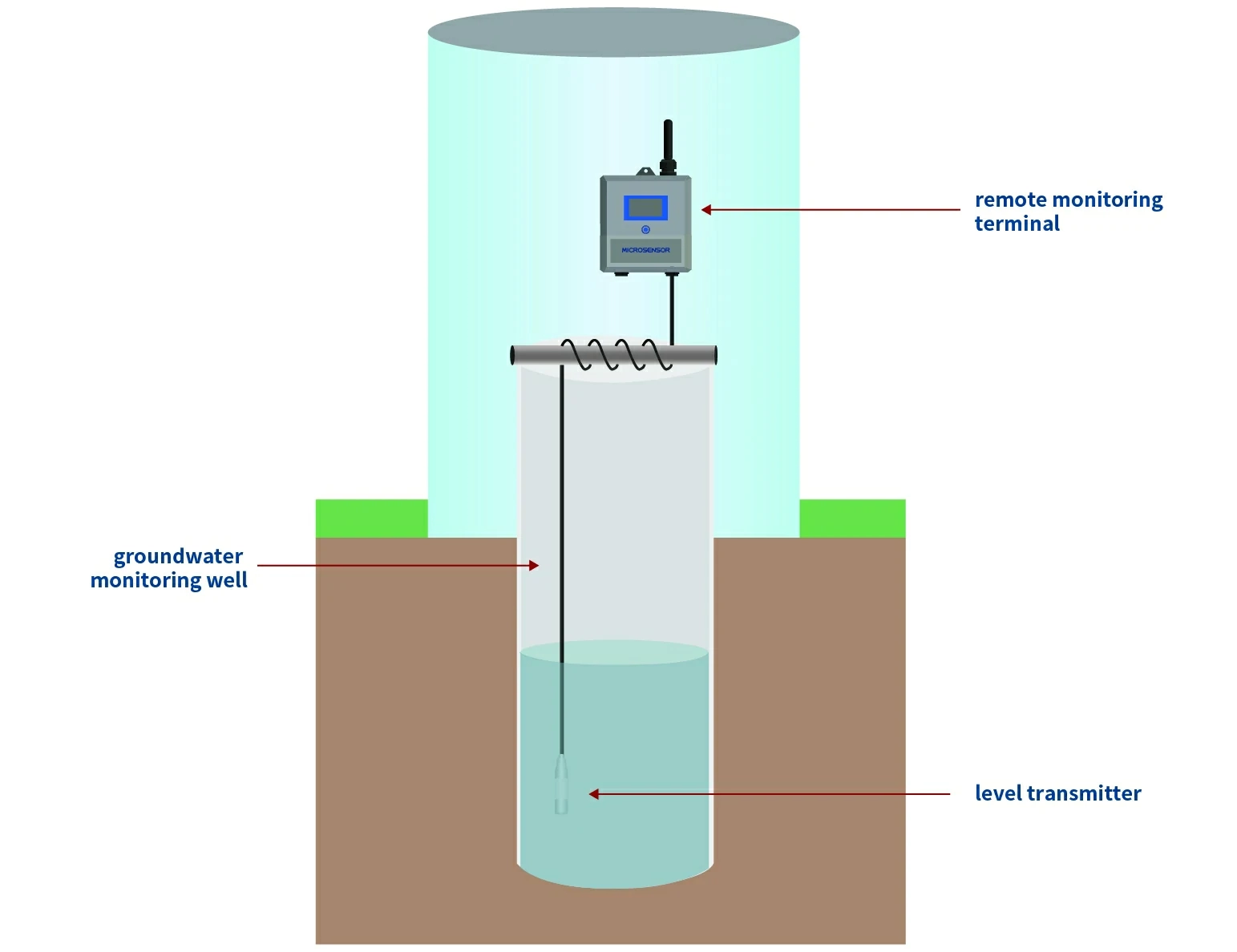

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

Rotary gas meter is the critical equipment in the system of urban gas gate station. As the basis of gas billing, rotary gas meter can accurately calculate the flow of natural gas. It is equipped with pressure transmitter with high accuracy, so as to guarantee the flow accuracy.

more info...

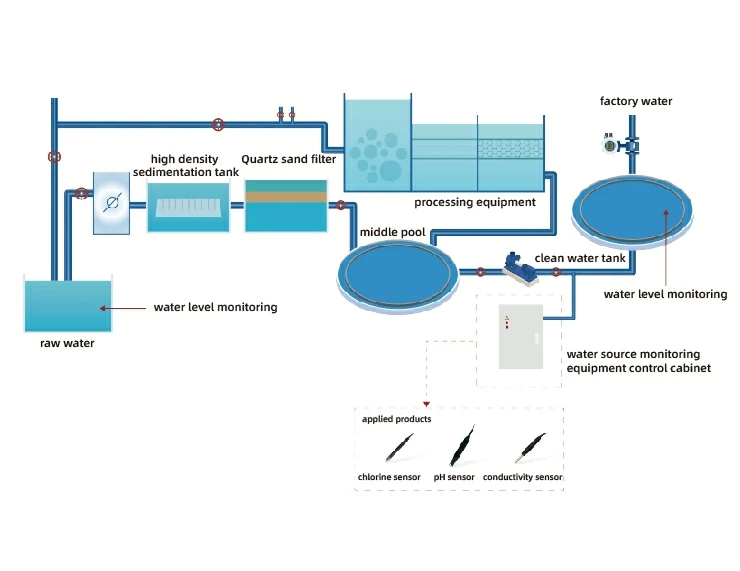

Pressure, flow, and level measuring instruments are deployed in water tanks, pipelines, and water inlets/outlets. This helps to manage the macro-control of production data in the water plant. Measuring instruments ensure smooth operation and normal production.

more info...

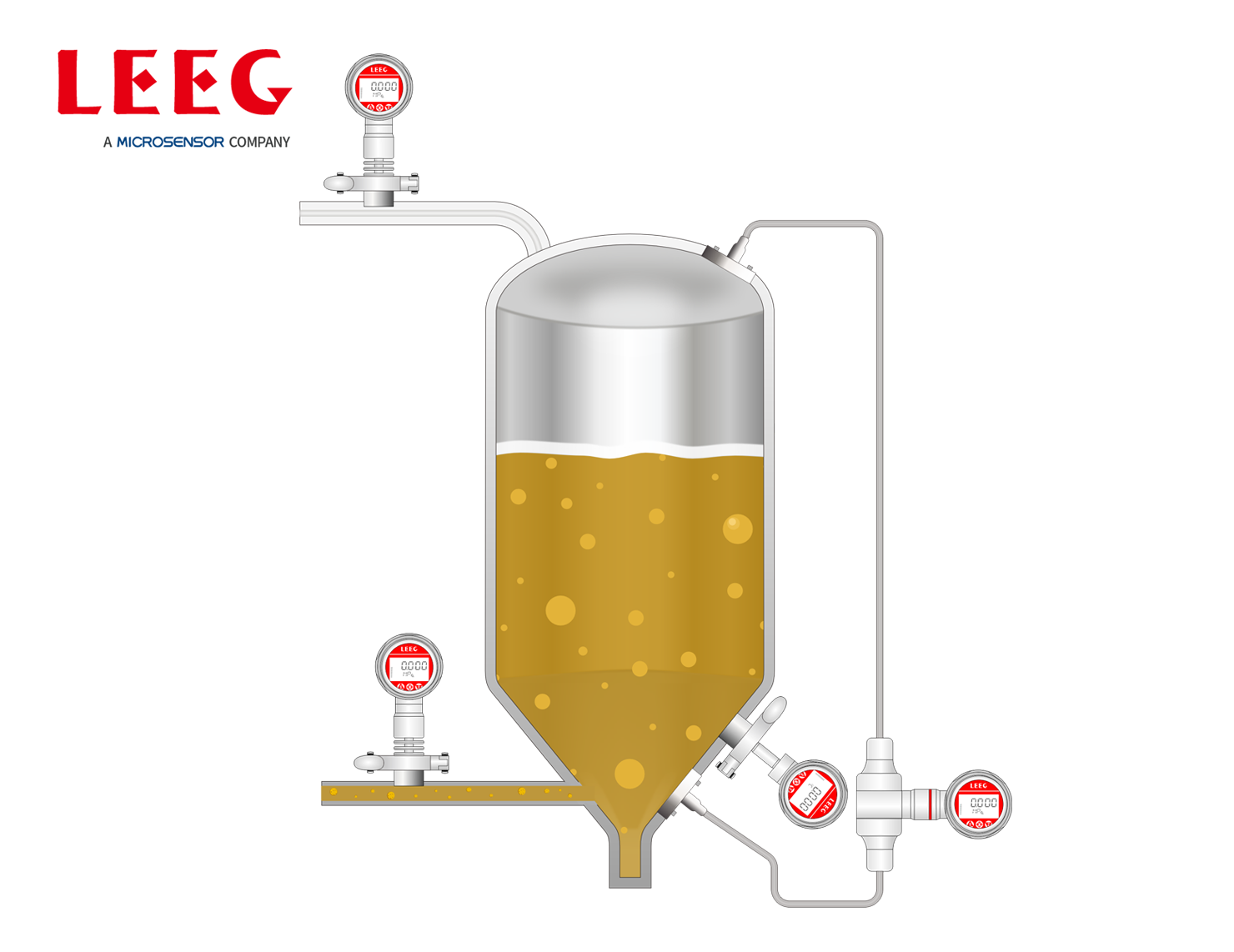

When the malt juice cools to the appropriate temperature, adding yeast initiates the fermentation process. During this process, yeast converts maltose dissolved in the malt juice into carbon dioxide and alcohol. To ensure a smooth fermentation process, it is necessary to measure the temperature and liquid level of the fermentation tank, as well as the carbon dioxide in the recovery pipe and the pressure in the yeast pipe.

more info...