Pressure and Temperature Sensor

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

MPM281VC

Used For

fluid gas and liquid pressure measurement

Leave a MessageMPM281VC is a piezoresistive pressure sensor silicon oil-filled. Its stainless steel 316L construction. The pressure sensor has a range of 0bar~0.35 bar…1000bar and gauge sealed gauge and absolute pressure type optional. MPM281VC pressure sensor has general dimensions by exciting with constant voltage 10VDC power supply and outputs a normalized signal 100+/2mV. It is very convenient for customers to make temperature compensation and amplify to a standard analog or digital output.

Samll size meet the requirement of installation with limited space. Custom design is available. It is very convenient for customers to make temperature compensation and amplify to a standard analog or digital output. The gas pressure transducer is suitable for fluid pressure measurement, such as gas, water, oil, etc.

Specification

• Dia: Φ19mm

• Power supply: ≤10V DC

• Pressure range 0bar~0.35bar…1000bar

• Housing: Stainless steel 316L

• Pin: Silicon rubber flexible wires

• O-ring: FKM

Image:

MPM281VC is a piezoresistive pressure sensor silicon oil-filled. Its stainless steel 316L construction. The pressure sensor has a range of 0bar~0.35 bar…1000bar and gauge sealed gauge and absolute pressure type optional. MPM281VC pressure sensor has general dimensions by exciting with constant voltage 10VDC power supply and outputs a normalized signal 100+/2mV. It is very convenient for customers to make temperature compensation and amplify to a standard analog or digital output.

Samll size meet the requirement of installation with limited space. Custom design is available. It is very convenient for customers to make temperature compensation and amplify to a standard analog or digital output. The gas pressure transducer is suitable for fluid pressure measurement, such as gas, water, oil, etc.

Specification

• Dia: Φ19mm

• Power supply: ≤10V DC

• Pressure range 0bar~0.35bar…1000bar

• Housing: Stainless steel 316L

• Pin: Silicon rubber flexible wires

• O-ring: FKM

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

Φ19mm standard OEM pressure sensor

Pressure range: 0 ~ 0.07bar…35bar

Long-term stability: ± 0.1%FS/Year

Range: -1bar…0bar~0.35bar…35bar

Output signal: Digital I²C (pressure, temperature)

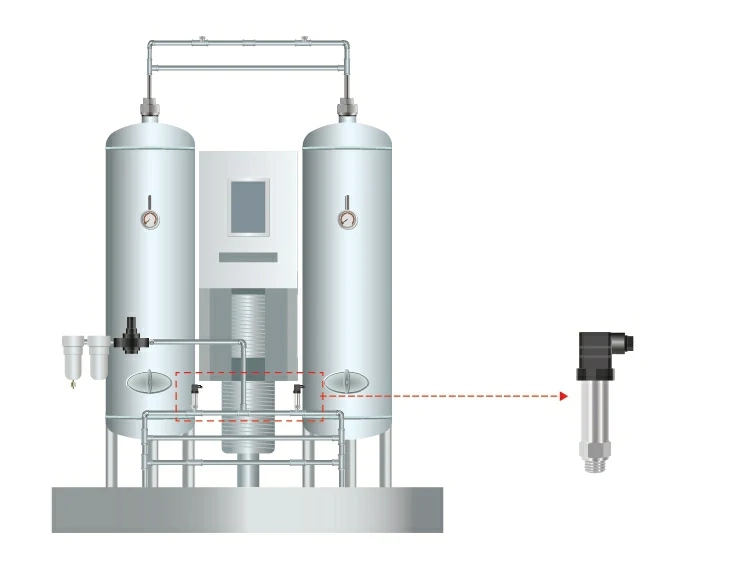

Nitrogen/oxygen generators are widely utilized in electronic equipment, medical devices, air conditioning refrigeration, and food & beverage industries. Pressure transmitters, being vital components of nitrogen/oxygen generators. They monitor the pressure within the container and throughout the variable pressure adsorption process.

more info...

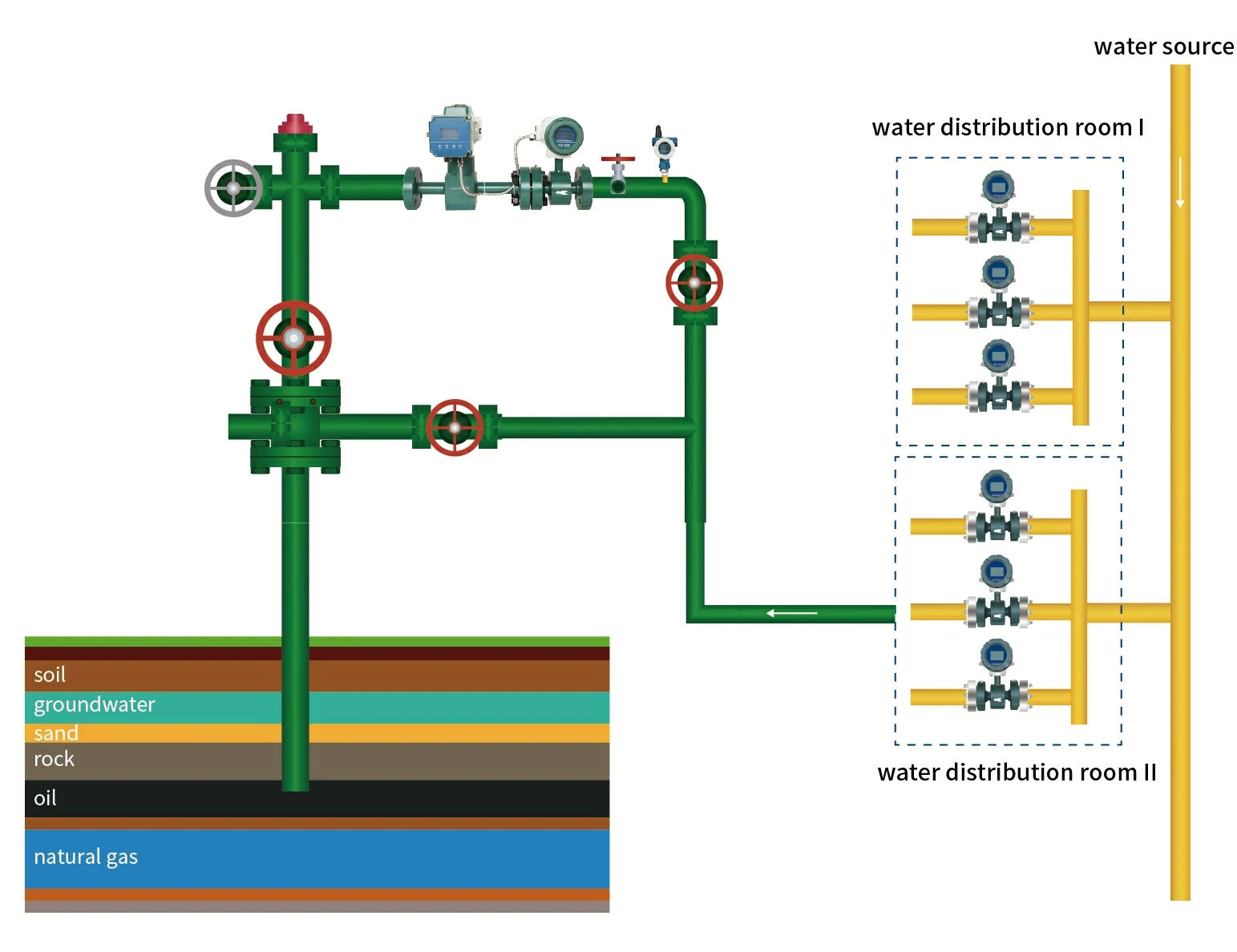

Install instruments like electromagnetic flowmeters, temperature/pressure transmitters, flow controllers in the pressure pumps, water injection pipelines, and water injection wells to monitor the water injection volume, pressure, and level changes in real time so that the pressure and volume of the well-injected water can be controlled.

more info...

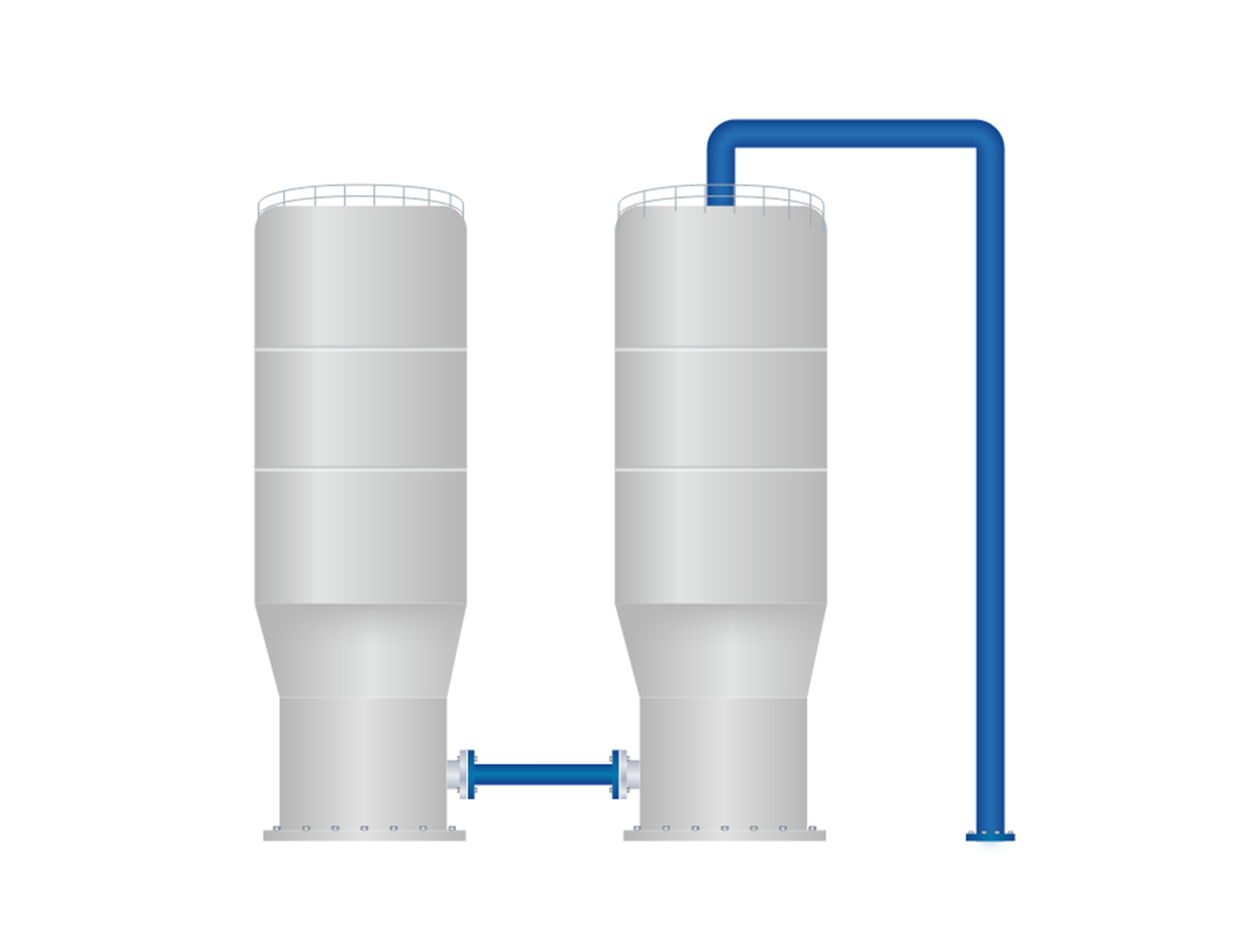

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

more info...