Piezoresistive Pressure Sensor

Φ19x11.5mm

0bar~0.35bar…1000bar

Constant Voltage Supply

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM288DI

Used For

Industrial Process Control, Smart Pressure Gauges, Medical Devices and IoT

Leave a MessageThe MPM288DI digital output pressure sensor outputs an I²C signal. The mature pressure chip production process and special conditioning chip make the product performance stable and reliable. Supply current in low power mode is <100nA. Therefore, MPM288DI is suitable for environments with high power consumption requirements.

Feature

• Cost-effective and compact

• Dual 24-bit ADC

• Full stainless steel 316L

Image:

The MPM288DI digital output pressure sensor outputs an I²C signal. The mature pressure chip production process and special conditioning chip make the product performance stable and reliable. Supply current in low power mode is <100nA. Therefore, MPM288DI is suitable for environments with high power consumption requirements.

Feature

• Cost-effective and compact

• Dual 24-bit ADC

• Full stainless steel 316L

Φ19x11.5mm

Pressure range -1bar…0bar~0.07bar… 1000bar

Silicone/Fluorocarbon oil filling options

Φ19×11.5mm

Pressure range: 0bar~0.35bar…1000bar

Gauge, absolute, sealed gauge

Φ19mm standard OEM pressure sensor

Pressure range: 0 ~ 0.07bar…35bar

Long-term stability: ± 0.1%FS/Year

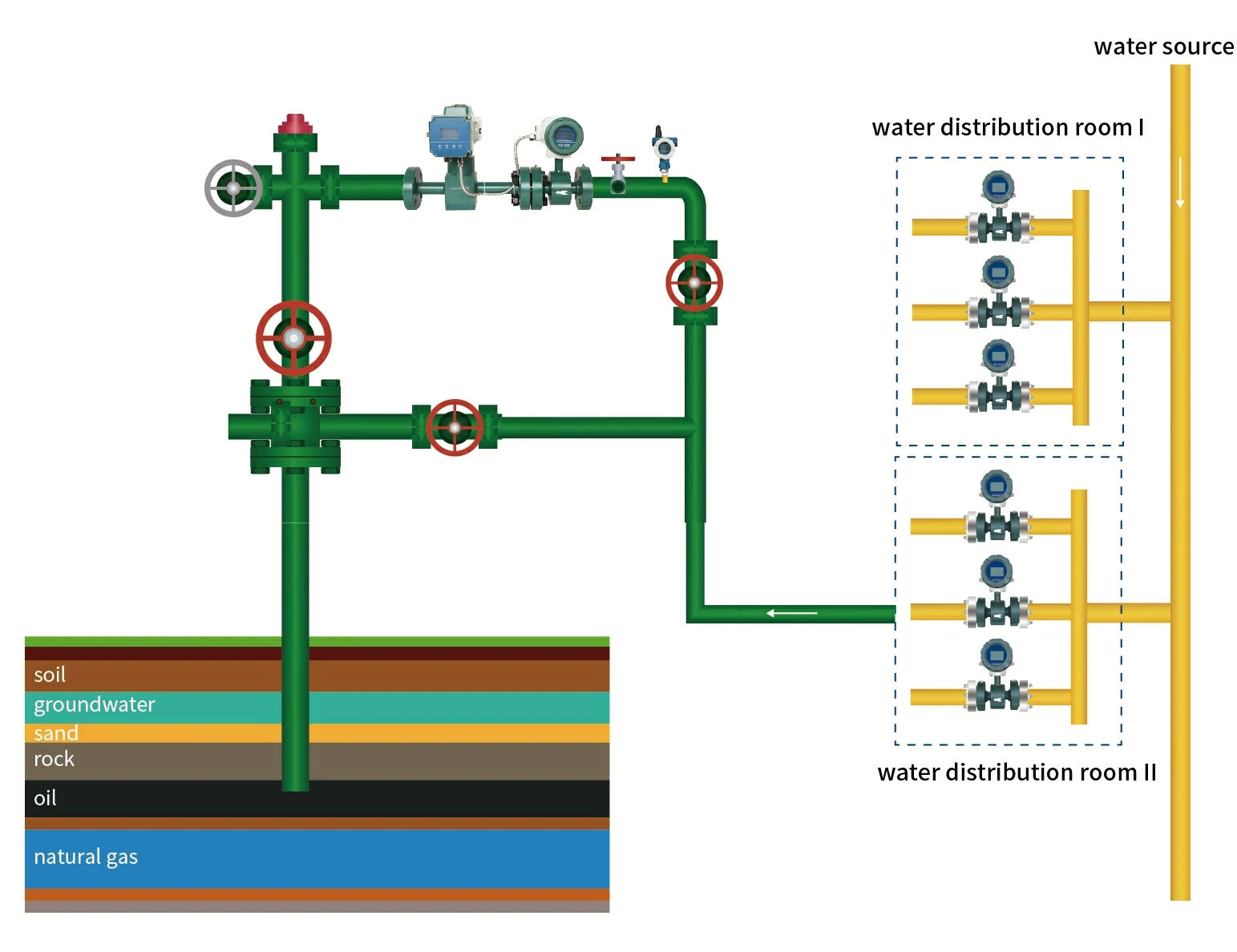

Install instruments like electromagnetic flowmeters, temperature/pressure transmitters, flow controllers in the pressure pumps, water injection pipelines, and water injection wells to monitor the water injection volume, pressure, and level changes in real time so that the pressure and volume of the well-injected water can be controlled.

more info...

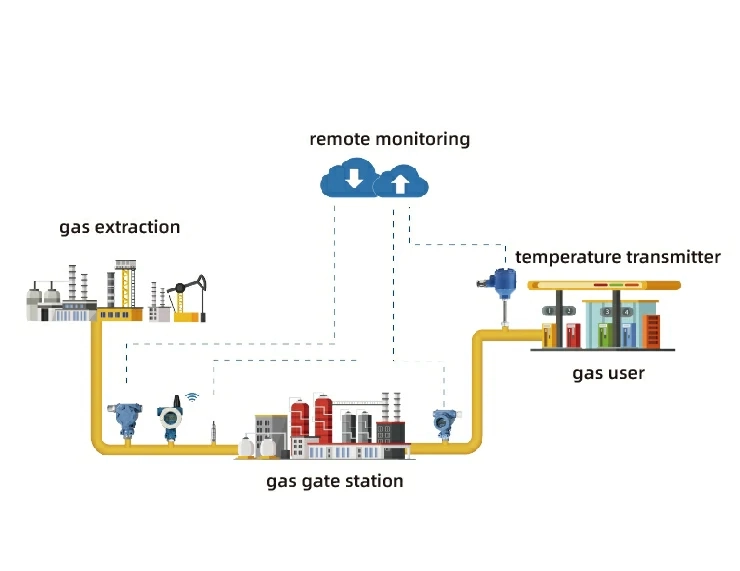

Natural gas undergoes a long process of transportation pipeline transmission, filtration, odorization, and pressure regulation from extraction to end-user consumption. In this process, monitoring the pressure and temperature within the pipeline is critical to ensuring the proper operation of the system.

more info...

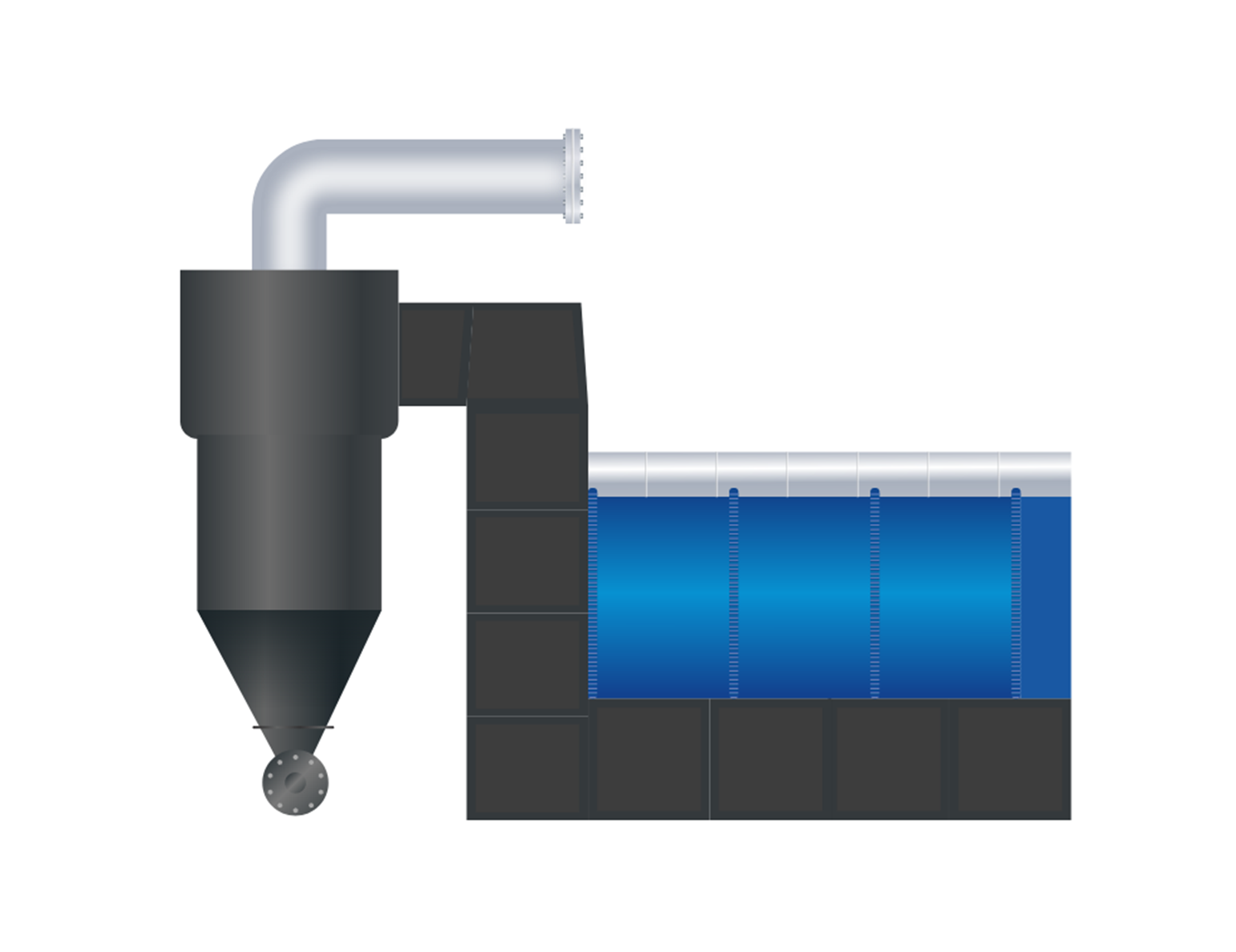

To eliminate any remaining moisture in the paper web, the paper machine's drying section uses rollers heated by steam. The inner cylinder surface develops a condensate coating as the steam loses heat, which affects the heat transfer to the paper. Continuous siphoning is required to remove this condensate. Pressure measurements at the cylinder inlet and outlet monitor the appropriate heat transfer level to the paper.

more info...

Inkjet printers are common equipment in the packaging and printing industry. Utilizing continuous inkjet technology, real-time pressure monitoring and early warning are necessary to ensure continuous and stable ink ejection, guaranteeing print quality.

more info...