Application Introduction

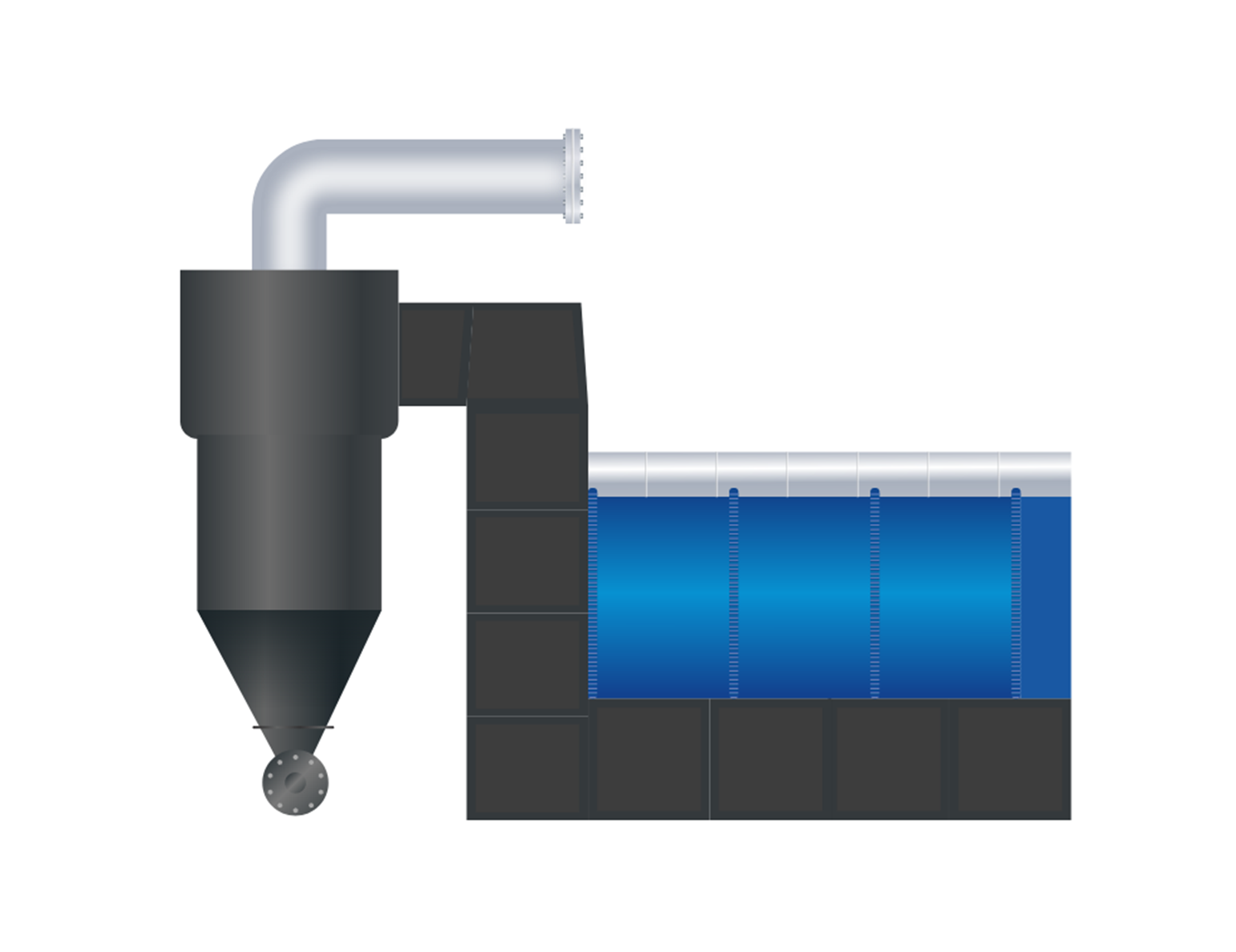

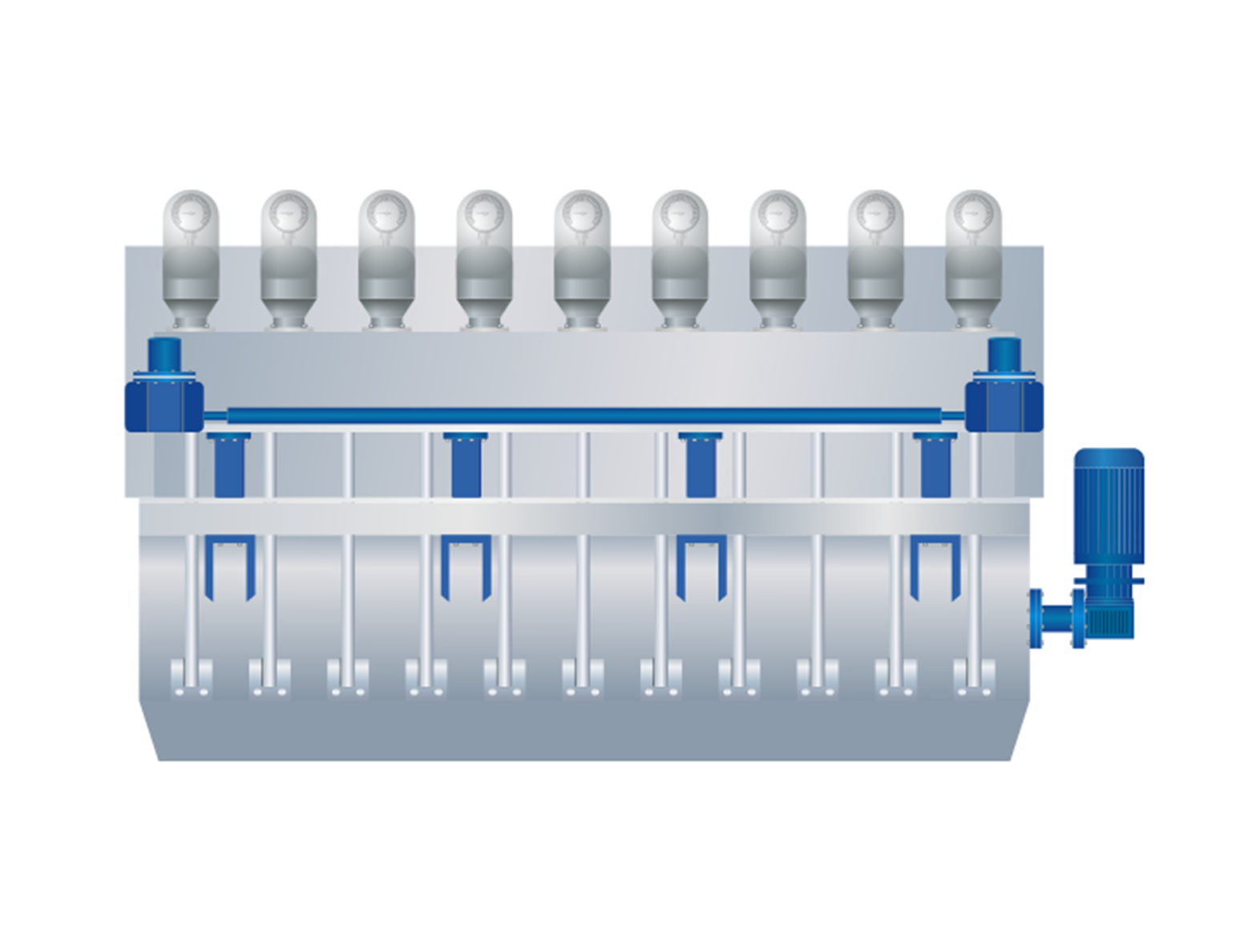

To eliminate any remaining moisture in the paper web, the paper machine's drying section uses rollers heated by steam. The inner cylinder surface develops a condensate coating as the steam loses heat, which affects the heat transfer to the paper. Continuous siphoning is required to remove this condensate. Pressure measurements at the cylinder inlet and outlet monitor the appropriate heat transfer level to the paper.

Contact Engineer

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD