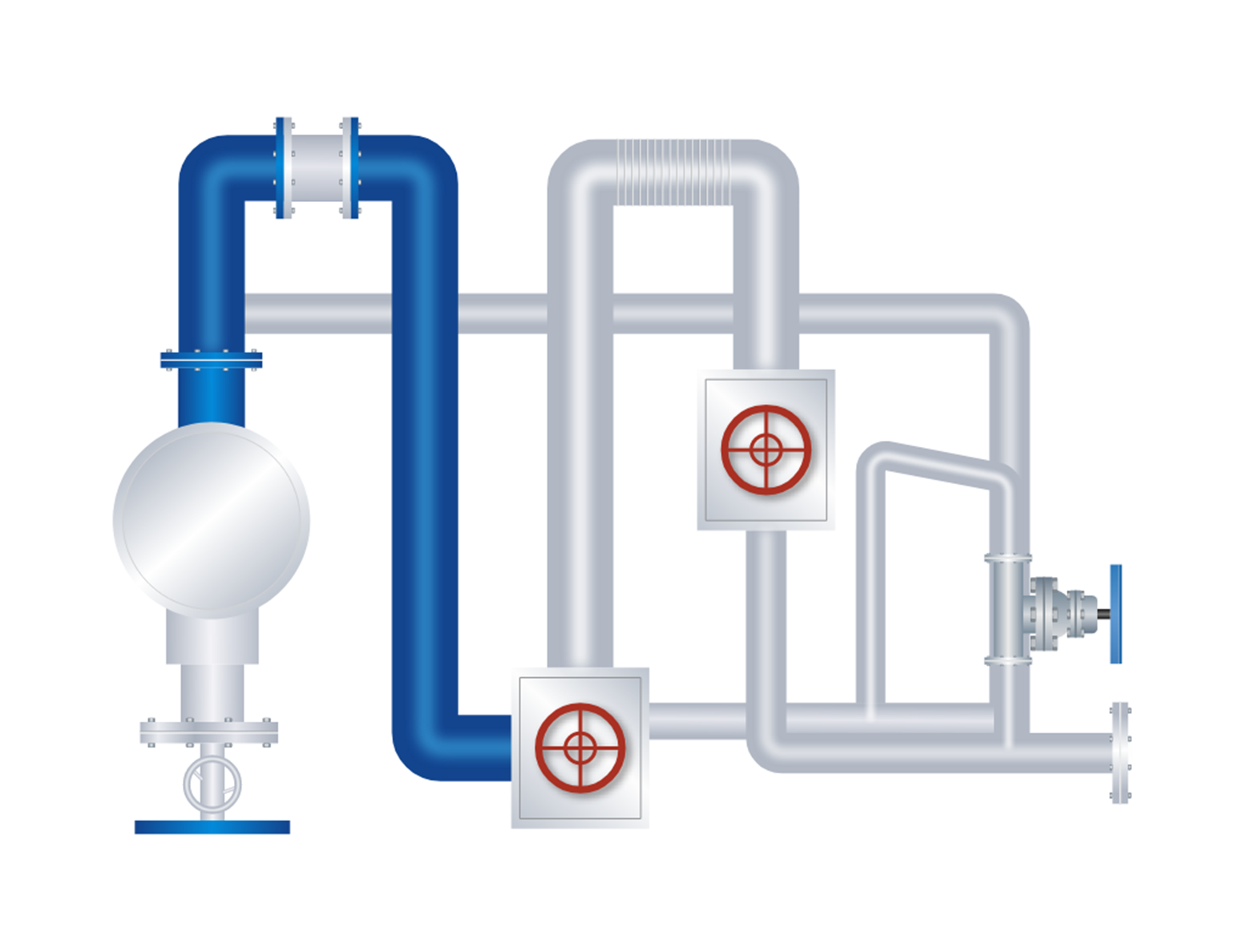

Application Challenges:

1. Instruments must perform reliably in vacuum pumps' high-temperature, high-humidity conditions.

2. To cope with the vacuum pump's frequent pressure variations, instruments must respond quickly and accurately.

3. Corrosion-resistant instrumentation materials and seals can withstand the corrosive slurries and chemicals used in vacuum pumps.

4. The non-homogeneity and high viscosity of slurries complicate measurements, increasing the possibility of flow errors.

Solution Advantages:

1. High-temperature, high-pressure-resistant materials provide stability even in harsh conditions.

2. Accurate sensors with high response speed monitor real-time pressure changes, ensuring system stability.

3. Long-term stability due to corrosion-resistant materials (stainless steel, Hastelloy, Teflon) .

4. Designed with anti-clogging constuction and self-cleaning function, adapting to media with different viscosities and fluidities, and providing accurate flow measurement.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD