The dual-output pressure transmitter is mainly used in aerial work platforms, elevating personnel fire trucks, intelligent shelving systems, beam transport vehicles, and beam lifting machines. These applications require high safety standards and often involve human operators, making operational safety critical. The dual-output sensors facilitate self-calibration and self-diagnosis during operation, preventing data inaccuracies due to sensor issues, and thereby ensuring the safety of equipment and personnel. The dual-output transmitter contains two independent signal conversion channels. Each channel can convert the input signal into the required complementary reverse output signal. One channel output is used as a measurement, and the other complementary output is used as a comparative fault judgment signal, which meets the PLd safety level in actual application. In addition, it also has safety functions such as startup diagnosis, cycle diagnosis, and sensor short circuit detection, meeting the safety redundancy standard.

Micro Sensor has developed a special MPM4511A dual-output pressure transmitter for aerial work platforms. While ensuring high accuracy, high stability and reliability, it improves the product's vibration and impact resistance.

Features

• Large pressure range: 0~350 bar

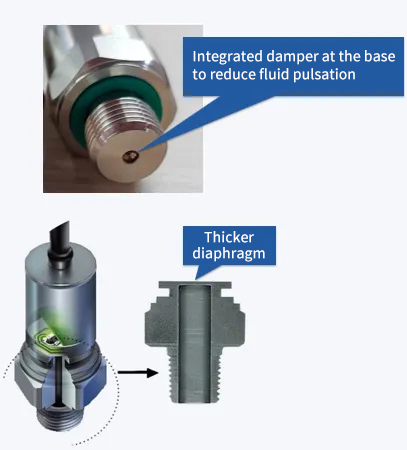

• High overpressure and overload capacity: Strong overload capacity; withstand 2-3 times overpressure.

• Anti-vibration: Anti-vibration ability; remain stable during operation and transportation.

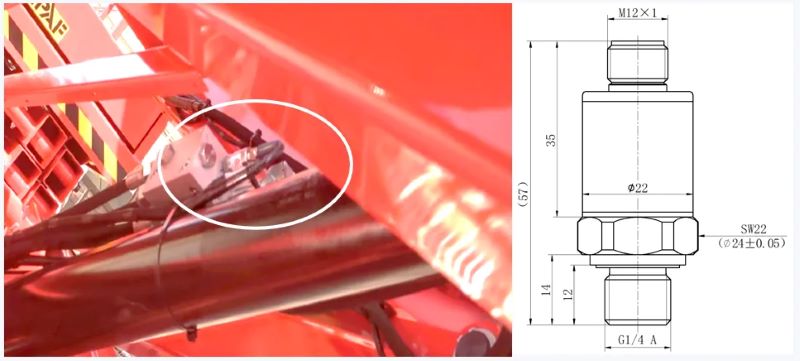

• Small installation space: Small and miniaturized valve block.

• Anti-shock: It can cope with the peak pressure caused by the sudden opening and closing of the valve or the instantaneous change of liquid flow direction

• Anti-electromagnetic interference: No interference from other equipment during operation, such as frequency converter

• Safety (dual output): With the load sensing system, two reverse signals, one as measurement and one as comparison fault judgment signal, meet PL d certification.

Specifications

• Pressure range: 0bar~350bar

• Pressure type: Gauge, sealed gauge pressure

• Output: 4mA~20mA&20mA~4mA; 0.5V~4.5V&4.5V~0.5V DC

• Operating temperature: -40℃~85℃

• Compensation temperature: -10℃~80℃

• Storage temperature: -40℃~125℃

• Accuracy: ±0.5%@25℃; ±1.0%FS@(-10~80)℃; ±2.0%FS@(-40~85)℃

• Long-term stability: ≤±0.25%FS/year (maximum value)

• Medium compatibility: compatible with 17-4PH

• Lifetime: 10 million cycles

• Vibration: 20g, 10Hz~2000Hz

• Shock: half-sine, 100g, 11ms

• Pressure port: G1/4A; M14×1.5; integrated damper

• Electrical connection: M12 connector (IP67)

• Electrical specifications (supply voltage): 9VDC~33VDC;

• Certificates: EN 13849-1 PL d Functional safety certification; CE; RoHS

• IP rating: IP67

• Insulation resistance: 250V/100MΩ

• EMC rating: EN IEC 61326-1:2021; Radiated immunity: 100V/m (80-1000MHz) ISO 11452-2

Applications

Hydraulic System for Aerial Work Platforms. Pressure transmitters are applied on the extending cylinder (also known as the lifting cylinder), providing cylinder pressure data to the safety assurance system. This enables the detection of changes in the working bucket's weight and helps prevent situations such as tipping due to overloading.

The MPM4511A pressure transmitter can be utilized not only in aerial work equipment but also in other hydraulic systems where high safety performance standards are required.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD