ATEX Pressure Transmitter

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4511A

Used For

Aerial Work Platform Hydraulic System, Hydraulic and Pneumatic System, Pumps or Compressors, HVAC, Hydraulic Servo Control System for Injection Molding Machine

Leave a MessageMPM4511A Hydraulic Pressure Transmitter is specially used in the construction machinery industry. MPM4511A uses glass micro-fused technology. The stainless steel integrated structure and damping structure can effectively resist the instantaneous pressure shock that may occur in the hydraulic system. MPM4511A hydraulic pressure sensor is particularly suitable for use in harsh environments and high work intensity.

Feature

• Measurement Accuracy: ±0.5%FS (25℃)

• Long-term Stability: ±0.25%FS/year

• High Overload, Excellent Anti-Interference

• Compact Structure, Multiple Structures Available

Image:

MPM4511A Hydraulic Pressure Transmitter is specially used in the construction machinery industry. MPM4511A uses glass micro-fused technology. The stainless steel integrated structure and damping structure can effectively resist the instantaneous pressure shock that may occur in the hydraulic system. MPM4511A hydraulic pressure sensor is particularly suitable for use in harsh environments and high work intensity.

Feature

• Measurement Accuracy: ±0.5%FS (25℃)

• Long-term Stability: ±0.25%FS/year

• High Overload, Excellent Anti-Interference

• Compact Structure, Multiple Structures Available

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

Heavy Duty & Shock Resistance

16Bar~1000Bar

Accuracy:±1%FS

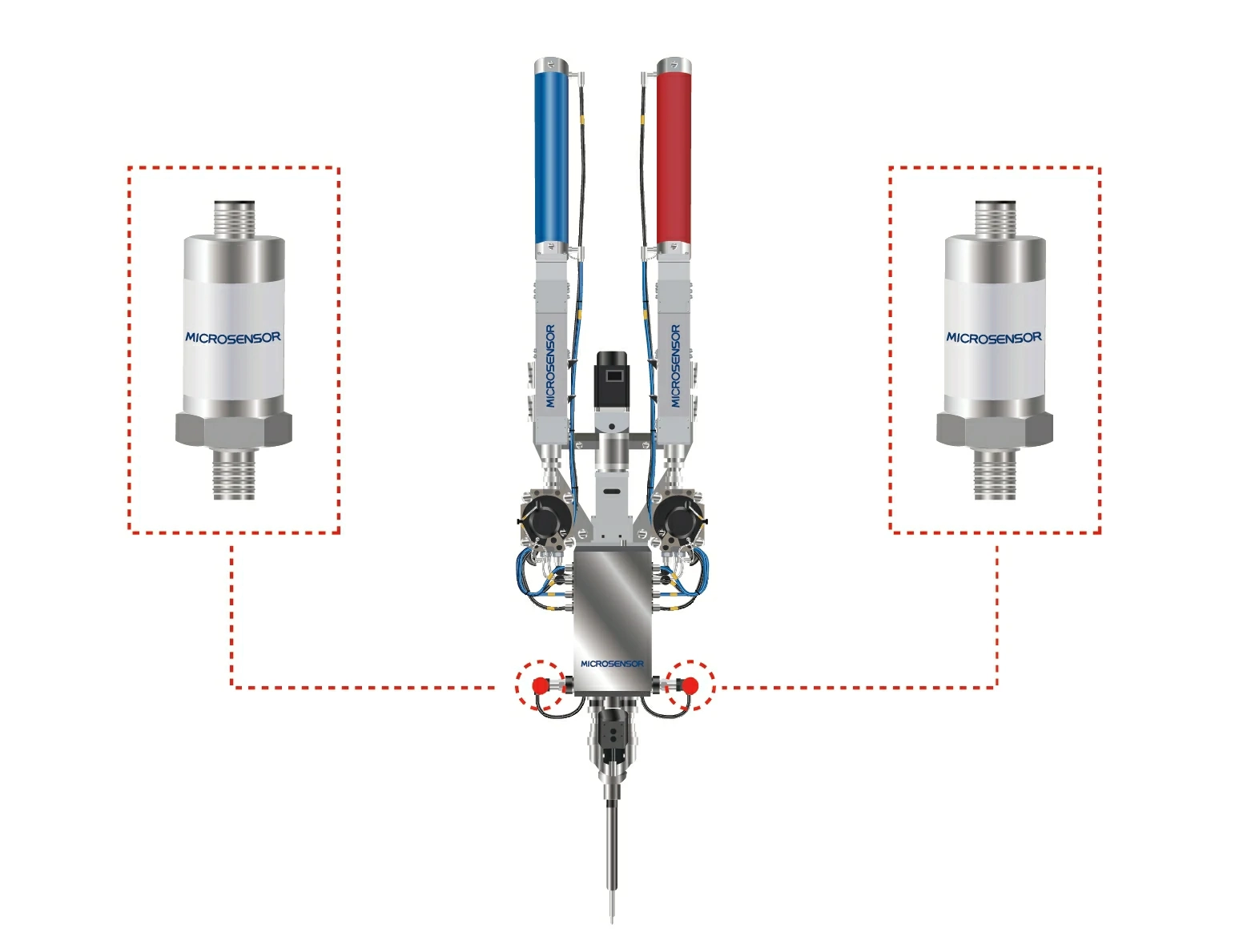

Dispensing machine is used to control adhesive, paint and other liquids. It requires compressed air to be fed into the glue bottle for proper operation. The role of the pressure transmitter is to monitor the pressure at the air inlet to ensure that the dispenser works properly.

more info...

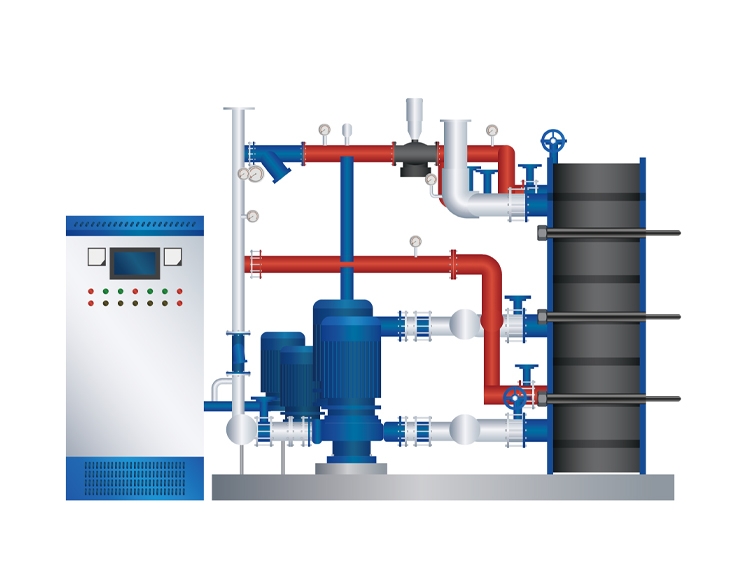

The marine temperature control system uses a refrigerant circulating between the condenser and evaporator to achieve cooling, heating, and dehumidification.

more info...

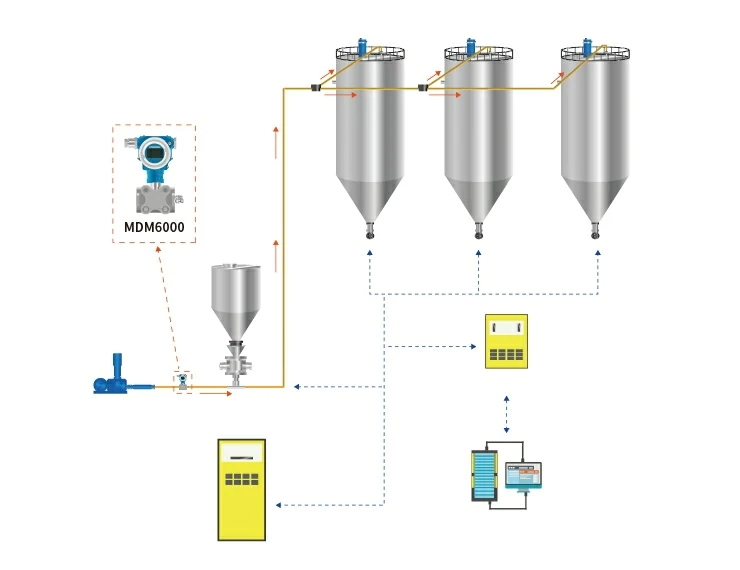

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...

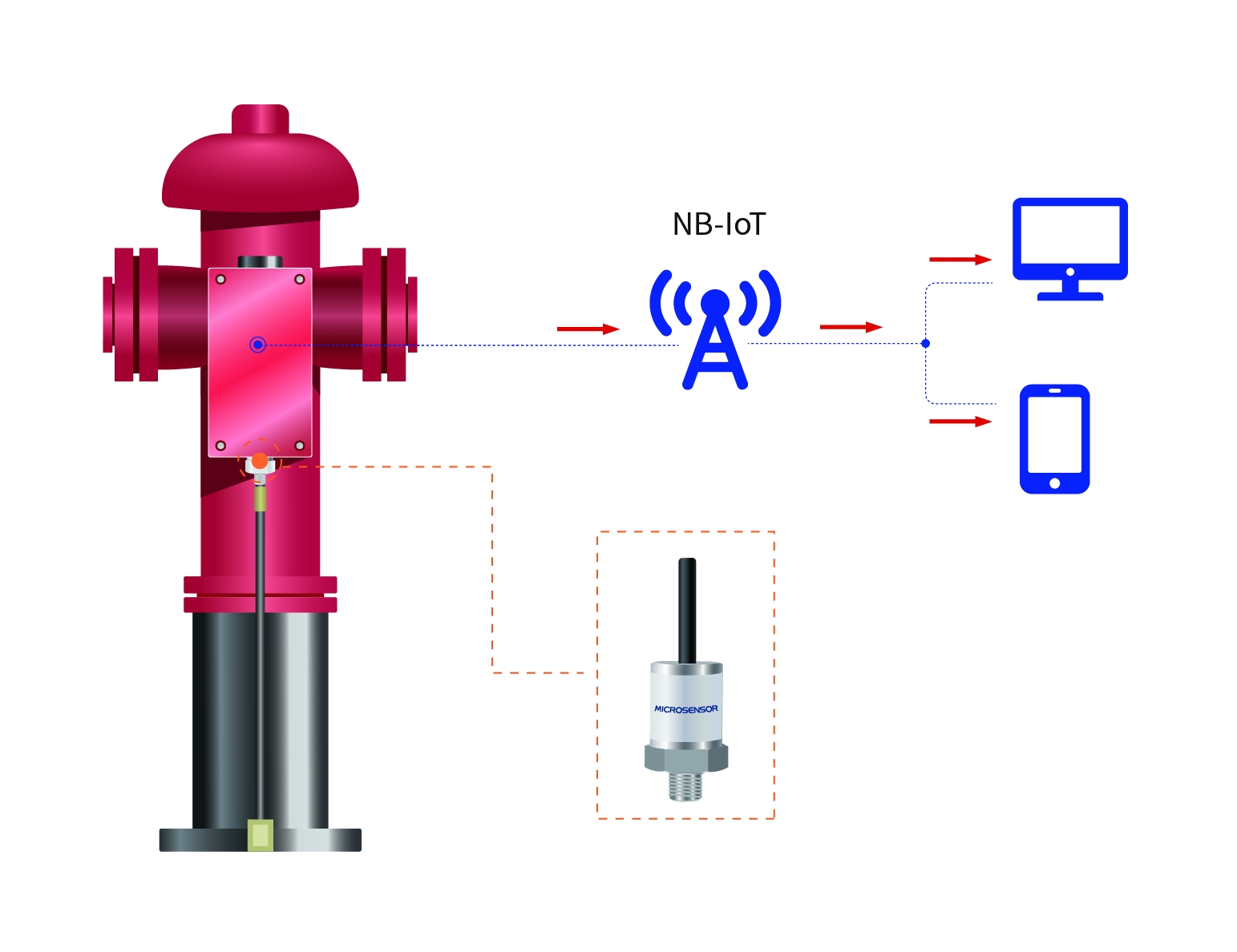

The micro-fused pressure transmitters can be used in hydrants to monitor the internal pressure of hydrants in real time, and send the data to the cloud platform for statistical analysis through wireless monitoring terminals and wireless networks. When an error occurs, it can locate the fault position and sends the alarm in time.

more info...