Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM489

Used For

Oil and Gas Industry, Hydrolpgy and Water Resources, Petroleum and Petrochemical Industry

Leave a MessageWith the piezoresistive pressure sensor technology, MPM489 gives outstanding linearity, repeatability, and hysteresis. With the robust circuit design, the MPM489 ATEX pressure transmitter features good resistance to EMI, and protection for instantaneous high pressure and surge interference of thunder, noise, sharp pulse, etc, which makes it work reliably and stably in a rough environment.

The MPM489 is an explosion-proof pressure transmitter designed for general industrial applications. It contains a piezoresistive sensing element of excellent stability and reliability, and a dedicated circuit that is housed in a high-strength stainless steel housing. Featuring an integrated structure, standard outputs, multiple process connections, and electrical connections, the product is an ideal solution for automation control applications that require precise measurement.

MPM489 pressure transmitter ranges -1bar…0mbar ~ 100mbar…1000bar with analog output signals such as 2-wire 4mA~20mA DC, 3-wire 0/1V~5/10V DC and 0.5V~2.5/4.5V DC.. Featuring 0.25%FS accuracy and an ATEX explosion-proof version available, the MPM489 is applicable in harsh environments and hazardous areas.

Features

• Explosion-proof type, Ex d IIC T6 Gb

• ATEX type, II 1 G Ex ia IIC T4 Ga

• CE, RoHS, CCS, ABS, and DNV approved

Image:

With the piezoresistive pressure sensor technology, MPM489 gives outstanding linearity, repeatability, and hysteresis. With the robust circuit design, the MPM489 ATEX pressure transmitter features good resistance to EMI, and protection for instantaneous high pressure and surge interference of thunder, noise, sharp pulse, etc, which makes it work reliably and stably in a rough environment.

The MPM489 is an explosion-proof pressure transmitter designed for general industrial applications. It contains a piezoresistive sensing element of excellent stability and reliability, and a dedicated circuit that is housed in a high-strength stainless steel housing. Featuring an integrated structure, standard outputs, multiple process connections, and electrical connections, the product is an ideal solution for automation control applications that require precise measurement.

MPM489 pressure transmitter ranges -1bar…0mbar ~ 100mbar…1000bar with analog output signals such as 2-wire 4mA~20mA DC, 3-wire 0/1V~5/10V DC and 0.5V~2.5/4.5V DC.. Featuring 0.25%FS accuracy and an ATEX explosion-proof version available, the MPM489 is applicable in harsh environments and hazardous areas.

Features

• Explosion-proof type, Ex d IIC T6 Gb

• ATEX type, II 1 G Ex ia IIC T4 Ga

• CE, RoHS, CCS, ABS, and DNV approved

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

Hydrogen Service Gold Plated Diaphragm

Range: 0mbar ~ 250mbar...70bar

Output Signal: 4~20mA 0/1~5/10V DC 0.5~4.5V DC 0.5~2.5V DC

Applicable for Hydraulic and Pneumatic

0bar~16bar …350bar

Accuracy:±0.5%FS

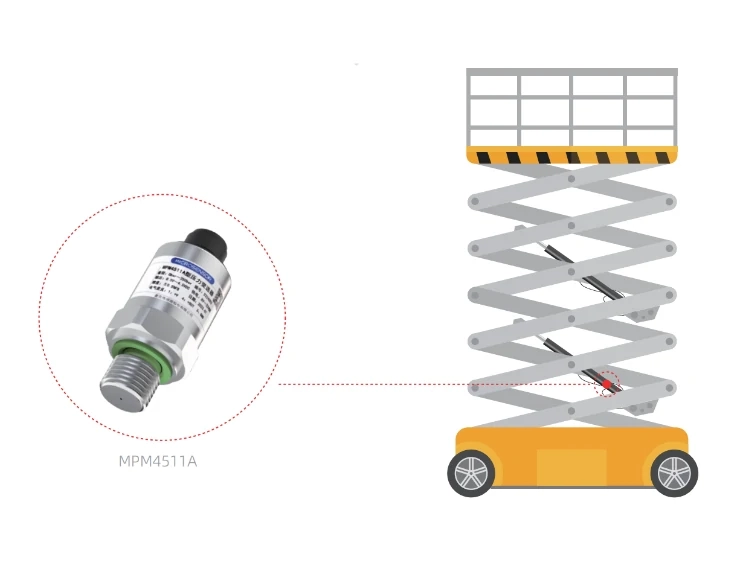

Aerial work platforms utilize hydraulic equipment for platform elevation to achieve high-altitude operations. In some fields, pressure transmitters are required to enable monitoring of operating conditions and fault diagnosis capabilities.

more info...

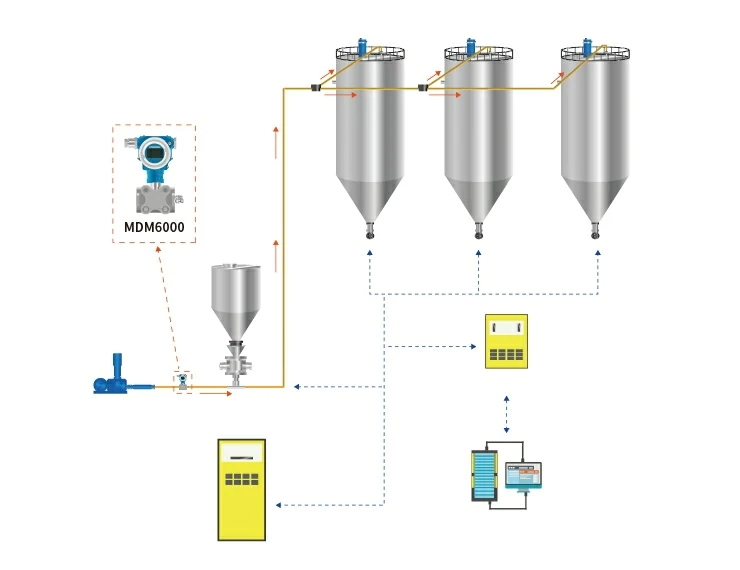

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...

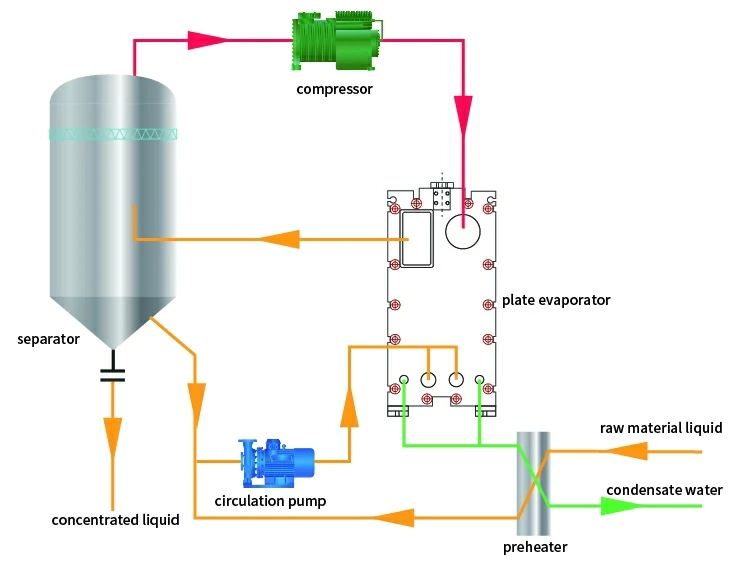

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

more info...

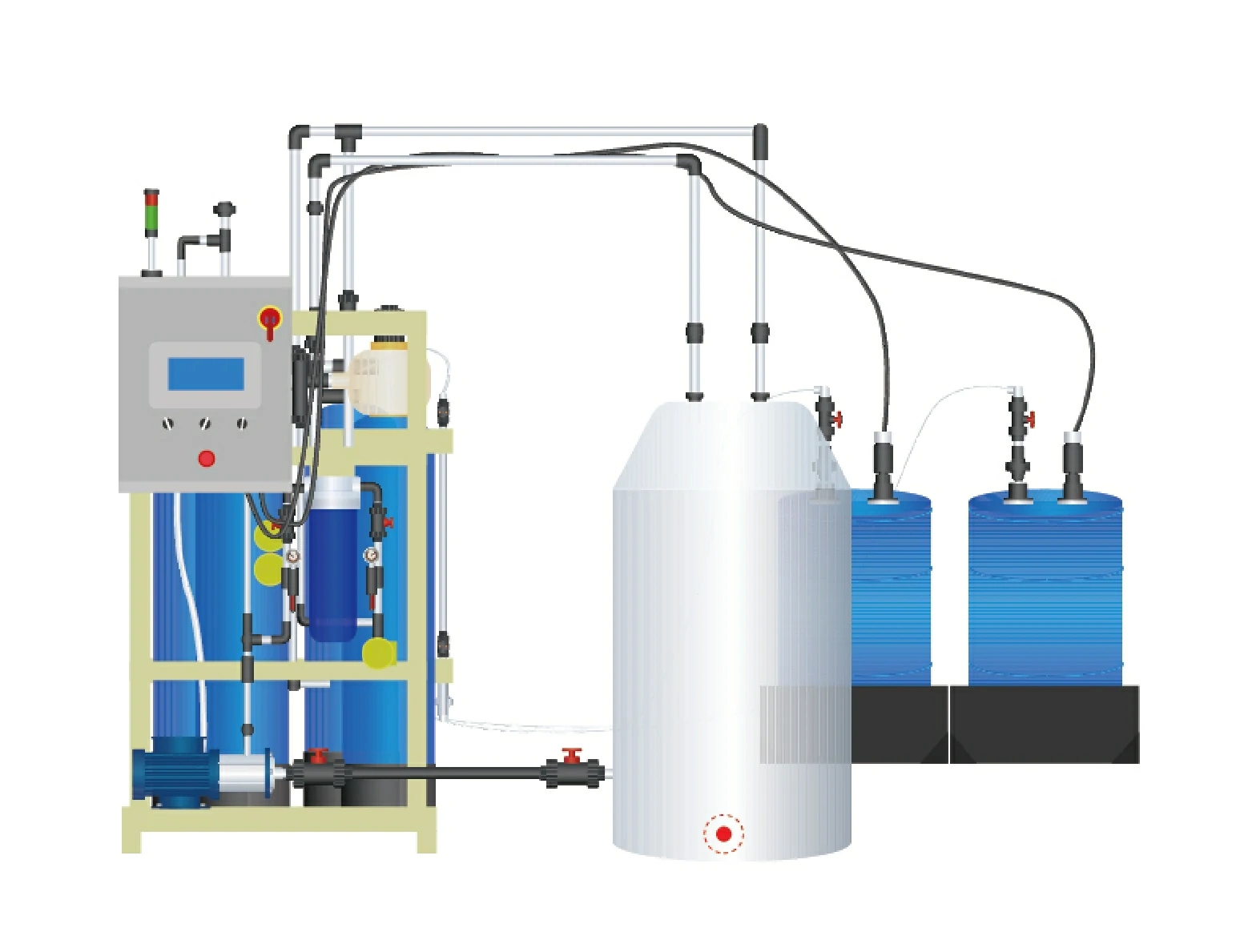

Deionized water is commonly used in industrial manufacturing cleaning processes. The target pressure values should be achieved during the production. It is necessary to monitor the pressure of the inlet and outlet. Only no blockages or leaks ensure normal operation of the production process.

more info...