Working Principle

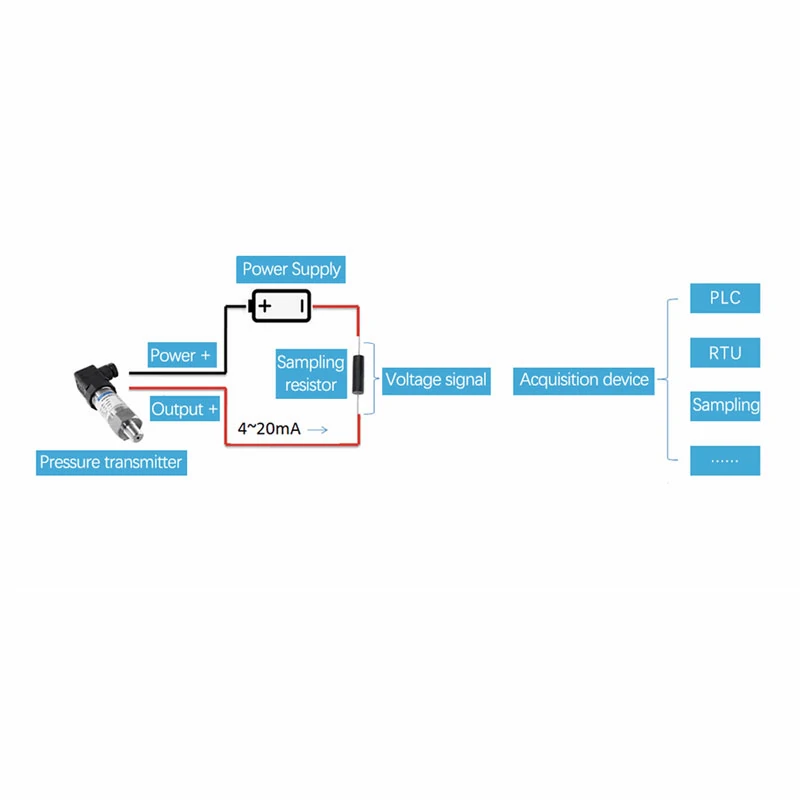

(Figure 1)

The typical usage of the two-wire 4-20mA pressure transmitter used by most customers is as shown in Figure 1. After the pressure transmitter is powered on, the loop current is proportional to the pressure. The collected pressure generates a 4-20mA signal. The current flows through the sampling resistor (typically 100Ω, 250Ω) in series with the loop. It is converted into a voltage signal for use by the back-end acquisition system. Typically, the sampling resistor is integrated into the acquisition device.

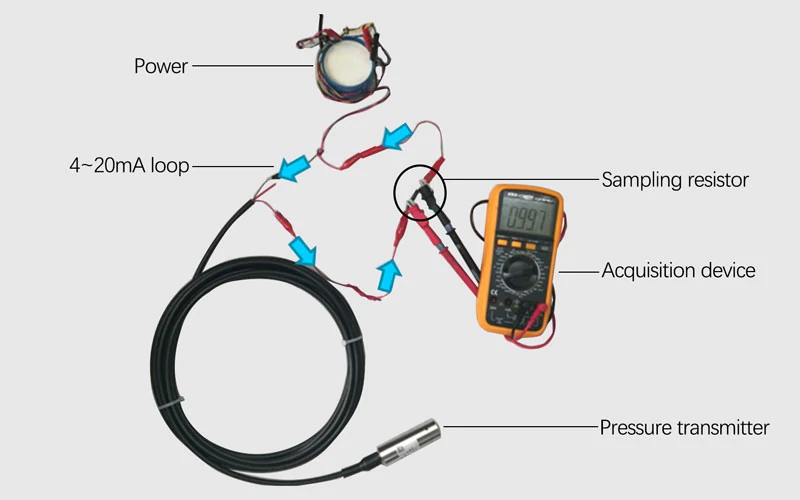

(Figure 2)

Figure 2 is a simulation diagram of the actual application. The blue arrow indicates 4-20mA current. A multimeter is used as the collection device. The sampling resistor is 250 ohms, the zero current is 4mA, and the collection voltage is about 0.997V (0.004mA×250 ohms=1V). )

Faults and Solutions

Common Fault 1:

The pressure signal is not collected and the value is abnormal.

This problem has many reasons, such as collection equipment problems, wiring errors or product quality problems. To solve this problem, please first ensure that the transmitter usually works after powering on.

Solution

A. Check Wiring:

Check the wiring according to the label on the transmitter housing or the manual. The black wire is generally the power supply for our products, and the red wire is the positive output.

If you find that the wires are reversed, don't worry about damage. Conventional products have an anti-reverse connection design. Please rewire the cable to solve the problem.

b. Measure Voltage:

After checking the wiring, adjust the multimeter to the voltage value and measure the voltage between the positive and negative outputs of the transmitter. The voltage value should be within the transmitter supply voltage range, which can be found on the product label or instruction manual.

If the measured voltage value is incorrect, please check whether the device is normal.

c: Measure Loop Current:

Disconnect the "positive output" of the transmitter, adjust the multimeter to the current range and insert it into the current loop to test the loop current value. Generally, the unpressurized state is about 4mA (the lower limit of the gauge pressure transmitter range is 0).

When performing the above tests, pay attention to the settings of the current and voltage ranges of the multimeter. Refer to the settings of the two multimeters above

After the above three steps, since the multimeter test is normal, if the loop current value is still not about 4mA (0.5% FS accuracy, 3.92~4.08mA), it can first be judged as a product failure. Please get in touch with the after-sales department for further analysis.

Common Fault 2:

The transmitter test is inaccurate, out of tolerance, and there is no change in pressure, etc.

Solution

(1) It is recommended to place the product statically in the air and check whether the power supply voltage is normal. Place the product vertically and test whether the circuit current of 4mA is accurate. For products with 0.5% FS accuracy, the zero current should be between 3.92 and 4.08mA.

(2) If the product has zero current and is normal, it is recommended to check whether the equipment is normal, whether the stop valve is open, whether the pressure pipe is blocked, etc.

(3) Check the pressure-sensing diaphragm of the transmitter. If the diaphragm is damaged, the transmitter can only be returned to the factory for repair.

(4) If the above method cannot solve the problem, don't hesitate to contact the after-sales department for further analysis.

Besides, we summarised 4 typical troubleshooting about 4~20mADC pressure transmitters to help customers solve the problems quickly on-site as below.

1. No Display, No Output

Check and Test | Solutions |

Check if the power supply is reversed. | Put it in the correct way. |

Check the power supply of the pressure sensor if it is 24VDC. | Make sure the pressure transmitter is power supplied ≥12V(intelligent type)≥15V(general type). If there is no power supply, check if the circuit is open and detect the secondary instrument/PLC sampling resistance (input impedance should be ≤250Ω). |

If it is a displayable pressure transmitter, check if the indicator is damaged (you can short the two wires of the indicator first. If it is normal after a short circuit, it means the indicator is damaged). | Replace the indicator. |

Connect the ammeter to the 24V power circuit and check if the current is normal. | If it is normal, the pressure transmitter is normal. In this case, check if other instruments in the circuit are normal. |

Check if the wiring is loose or not. | Make it tightened and well connected. |

Check if the power supply is correctly connected to the power input terminal. | Connect to the power supply terminal correctly according to the power supply requirements. |

2. The Pressure transmitter output is ≥20mA.

Check and Test | Solutions |

Check if the pressure transmitter power supply is normal. | If it is less than 12VDC, check whether there is a large load in the circuit. The load capacity of the pressure transmitter should be in accordance with RL ≤(transmitter supply voltage -12V)/( 0.02A) Ω. |

Check whether the actual pressure exceeds full range limits. | Change a pressure transmitter with an appropriate range. |

Check whether the pressure sensor is damaged. Severe overload sometimes damages isolated diaphragm. | Return the pressure transmitter to the factory for maintenance. |

Check whether the power supply wiring is correct. | Put it in an incorrect way. |

3. The pressure transmitter output is ≤4mA.

Check and Test | Solutions |

Check if the pressure transmitter power supply is normal. | If it is less than 12VDC, check whether there is a large load in the circuit. The load capacity of the pressure transmitter should be in accordance with RL≤ (transmitter supply voltage -12V) / ( 0.02A) Ω. |

Check whether the wiring is loose or not which causes the contact resistance to increase. It is equivalent to the load increase. | Connect the wire and tighten it, the load is in accordance with RL≤ (transmitter supply voltage-12V) /(0.02A) Ω. |

Check whether the actual pressure exceeds the selected range of the pressure transmitter. | Change a pressure transmitter with an appropriate range. |

Check whether the pressure sensor is damaged. Severe overload sometimes damages the isolated diaphragm | Return the pressure transmitter to the factory for maintenance |

4. Wrong display/output signal with the error.

Check and Test | Solutions |

Check if the pressure transmitter power supply is normal. | If it is less than 12VDC, check whether there is a large load in the circuit. The load capacity of the pressure transmitter should be in accordance with RL ≤ (transmitter supply voltage -12V)/( 0.02A) Ω. |

Check if the reference pressure value is correct. | Replace the same type of pressure transmitter. If the error is consistent, check the reference pressure meter. If the meter's accuracy is low, you need to change the instrument with higher precision. |

Check if the range of the secondary meter is consistent with the range of the pressure transmitter. | Adjust the range of the secondary instrument to make sure it is consistent with the range of the pressure transmitter. |

The capacity of the pressure transmitter load should be in accordance with RL≤ (transmitter supply voltage -12V)/(0.02A) Ω. | If it is not, take measures according to its different conditions: such as raising the power supply voltage (but must be lower than 36VDC), reducing the load, etc. |

Check if the corresponding device housing is reliably grounded. | If not, make it reliably grounded. |

Check whether the strong and weak electricity is separately arranged onsite. | Make sure the wiring is scientific and reasonable, avoiding interference for pressure transmitter signal instability/error. |

The pressure sensor diaphragm is easily deformed. Overload and hard objects may damage the isolated diaphragm. | Return the pressure transmitter to the factory for maintenance. |

Check the pipeline When the pipeline has impurities, the measurement accuracy will be affected. | Clean the impurities and add a filter screen before the pressure port. |

Contact Us

Micro Sensor provides product solutions for practical industrial applications, please contact us via sales@microsensor.cn and we are dedicated to serving you with custom design products and solutions!

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD