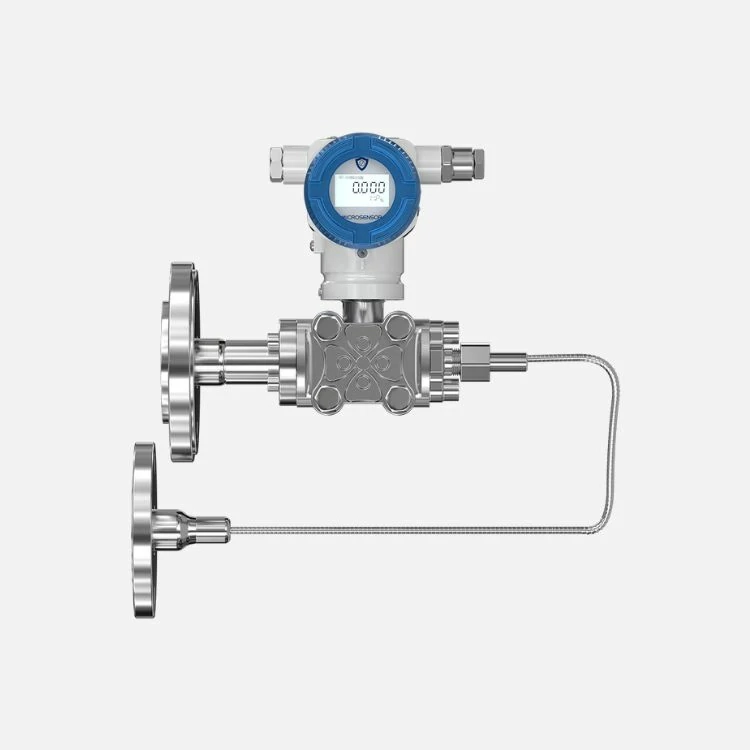

Smart Differential Pressure Transmitter With Remote Diaphragm Seal

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MDM7000-DGP/DAP

Used For

Oil and Gas Industry, Food Processing Industry, Chemical Industry, Marine Industry

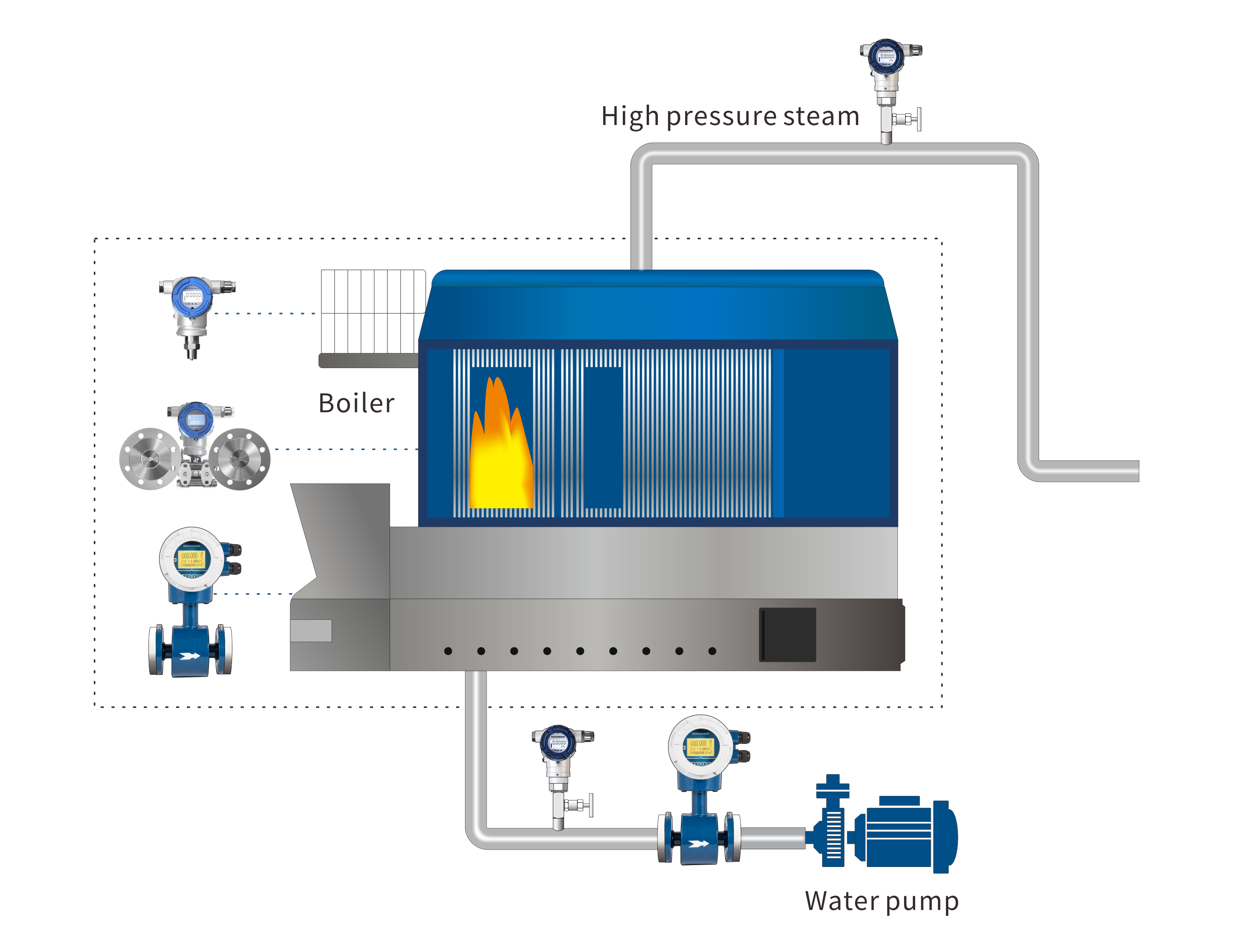

Leave a MessageThe MDM7000-DGP/DAP Intelligent Differential Pressure Mounted Gauge / Absolute Pressure Transmitter is designed to meet the high demands of the process industry. The monocrystalline silicon piezoresistive technology ensures stable performance with an accuracy of 0.075%FS and a maximum ratio of 100:1, which is ideal for flexible adjustment of the measurement range. The pressure signal can be converted to a 4mA~20mA DC analogue current signal output for remote setup, monitoring and other functions via communication devices. The precision pressure transducer is essential for measuring the level, density, pressure and flow of liquids, gases or vapors.

As the smart pressure transmitter, the MDM7000-DGP/DAP adopts a high-performance EMC protection circuit module with high anti-interference capability. It also offers excellent long-term stability (±0.2% SPAN/5 years). Its ruggedness and wide range of applications make it applicable for the process industry.

Features

• Adopts high performance EMC protection

• Circuit module with strong anti-interference ability

• Excellent long-term stability: ±0.1% SPAN/10 years

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Image:

The MDM7000-DGP/DAP Intelligent Differential Pressure Mounted Gauge / Absolute Pressure Transmitter is designed to meet the high demands of the process industry. The monocrystalline silicon piezoresistive technology ensures stable performance with an accuracy of 0.075%FS and a maximum ratio of 100:1, which is ideal for flexible adjustment of the measurement range. The pressure signal can be converted to a 4mA~20mA DC analogue current signal output for remote setup, monitoring and other functions via communication devices. The precision pressure transducer is essential for measuring the level, density, pressure and flow of liquids, gases or vapors.

As the smart pressure transmitter, the MDM7000-DGP/DAP adopts a high-performance EMC protection circuit module with high anti-interference capability. It also offers excellent long-term stability (±0.2% SPAN/5 years). Its ruggedness and wide range of applications make it applicable for the process industry.

Features

• Adopts high performance EMC protection

• Circuit module with strong anti-interference ability

• Excellent long-term stability: ±0.1% SPAN/10 years

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP Accuracy:±0.075%, ±0.1%FS, ±0.2%URL

MDM7000-AP Accuracy:±0.1%, ±0.2%URL

MDM7000-GP Range:0.4bar ~400bar

MDM7000-AP Range:0.1bar~100bar

Long-term stability:±0.1% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.075%URL

Range: 0.4bar~2.5bar

Output Signal: 4mA~20mA DC, HART

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP-T Accuracy:±0.1%、±0.2%URL

MDM7000-AP-T Accuracy:±0.1%、±0.2%URL

MDM7000-GP-T Range:0.4bar~100bar

MDM7000-AP-T Range:0.4bar~10bar

DNV, ABS, KR, NK, and RS approved for installation on vessels

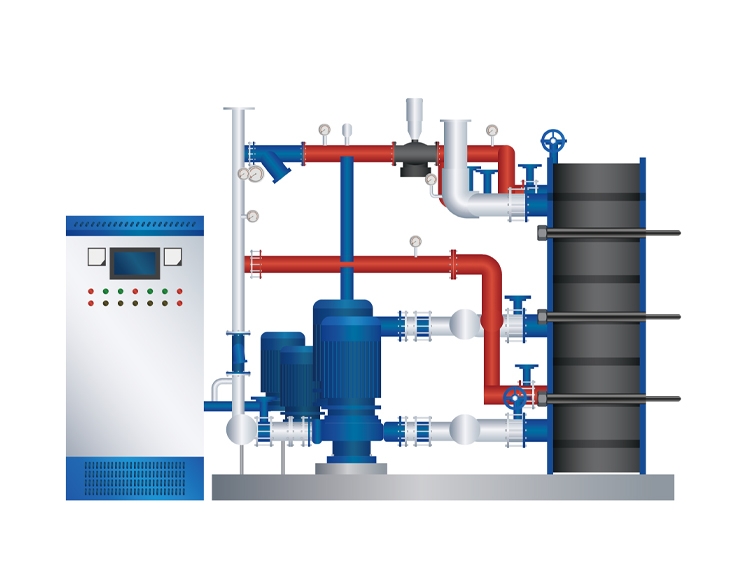

The marine temperature control system uses a refrigerant circulating between the condenser and evaporator to achieve cooling, heating, and dehumidification.

more info...

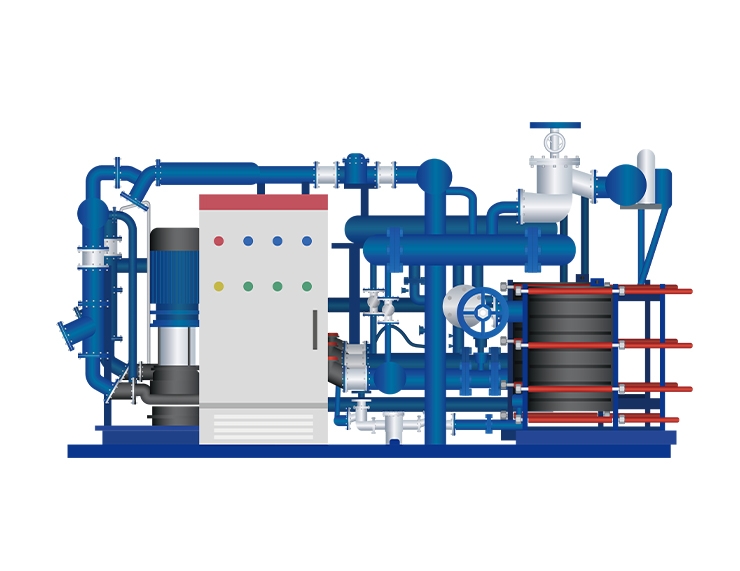

Pressure transmitters, temperature tranmitters and electromagnetic flowmeters are installed in the marine water circulation cooling system to ensure the heat exchange efficiency of the central cooler. By optimizing seawater flow control, energy saving effects are maximized and stable operation of the cooling system is ensured.

more info...

In the electric power industry, especially in power plants and transmission systems, it is very important to accurately monitor and control pressure, level, temperature and flow, because these specifications will directly affect the operating efficiency and safety of the system. Micro Sensor's monitoring instrumentation solutions integrate advanced sensor technology and intelligent control systems, which can provide accurate data and efficient control even in complex environments, and optimize the power production and transmission process.

more info...

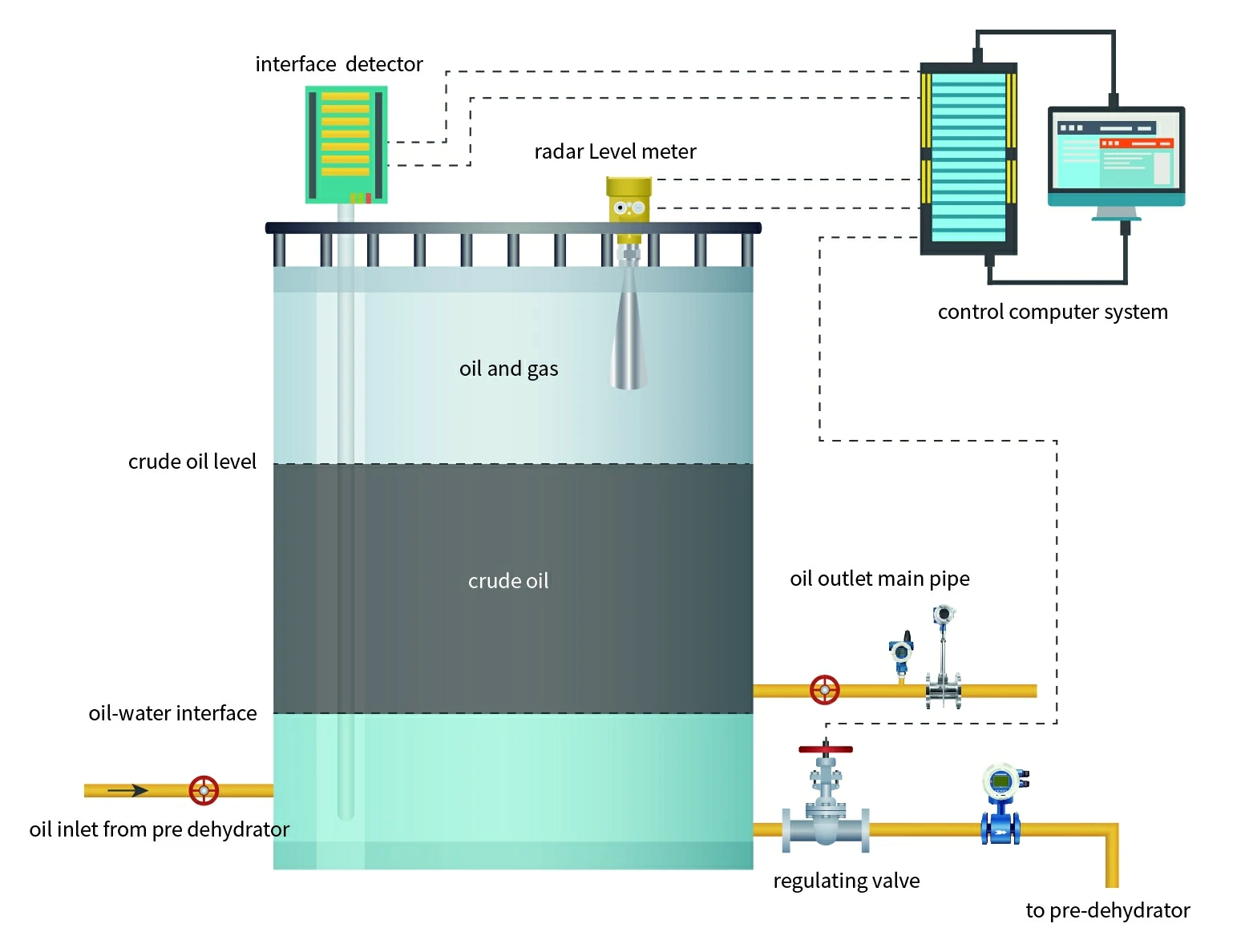

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...