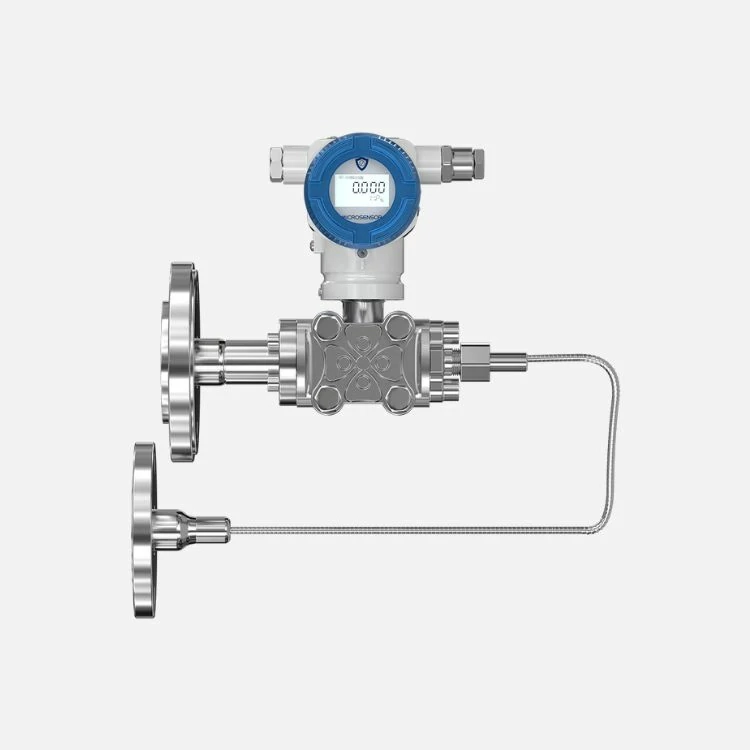

Smart Differential Pressure Transmitter With Remote Diaphragm Seal

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MDM7000-GP-T/AP-T

Used For

Oil and Gas Industry, Food Processing, Pulp and Paper, Power and Energy, Chemical Industry

Leave a MessageMDM7000-GP-T/AP-T intelligent pressure absolute/gauge pressure transmitter is a highly accurate product to measure the level/surface, density, and flow of liquids, gases, mixtures, etc. The product is explosion-proof certified for safe operation in hazardous environments.

Features

• High precision: ±0.1% , ±0.2%URL

• Long-term stability: ±0.1% SPAN/10 years

• 4~20mA DC, HART communication protocol, and industrial bus protocol such as RS485-Modbus

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Image:

MDM7000-GP-T/AP-T intelligent pressure absolute/gauge pressure transmitter is a highly accurate product to measure the level/surface, density, and flow of liquids, gases, mixtures, etc. The product is explosion-proof certified for safe operation in hazardous environments.

Features

• High precision: ±0.1% , ±0.2%URL

• Long-term stability: ±0.1% SPAN/10 years

• 4~20mA DC, HART communication protocol, and industrial bus protocol such as RS485-Modbus

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP Accuracy:±0.075%, ±0.1%FS, ±0.2%URL

MDM7000-AP Accuracy:±0.1%, ±0.2%URL

MDM7000-GP Range:0.4bar ~400bar

MDM7000-AP Range:0.1bar~100bar

Long-term stability:±0.1% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.075%URL

Range: 0.4bar~2.5bar

Output Signal: 4mA~20mA DC, HART

DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.05%, ±0.075%URL

Range: 20mbar~100bar

Long-term stability: ±0.1% Span/10 years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

Pressure transmitters, level transmitters, and mass flow meters are installed in fuel tanks to provide real-time monitoring of fuel levels and pressure. Users can track current location and fuel consumption, access historical vessel data, calculate voyage distance and total fuel usage, and analyze operational efficiency.

more info...

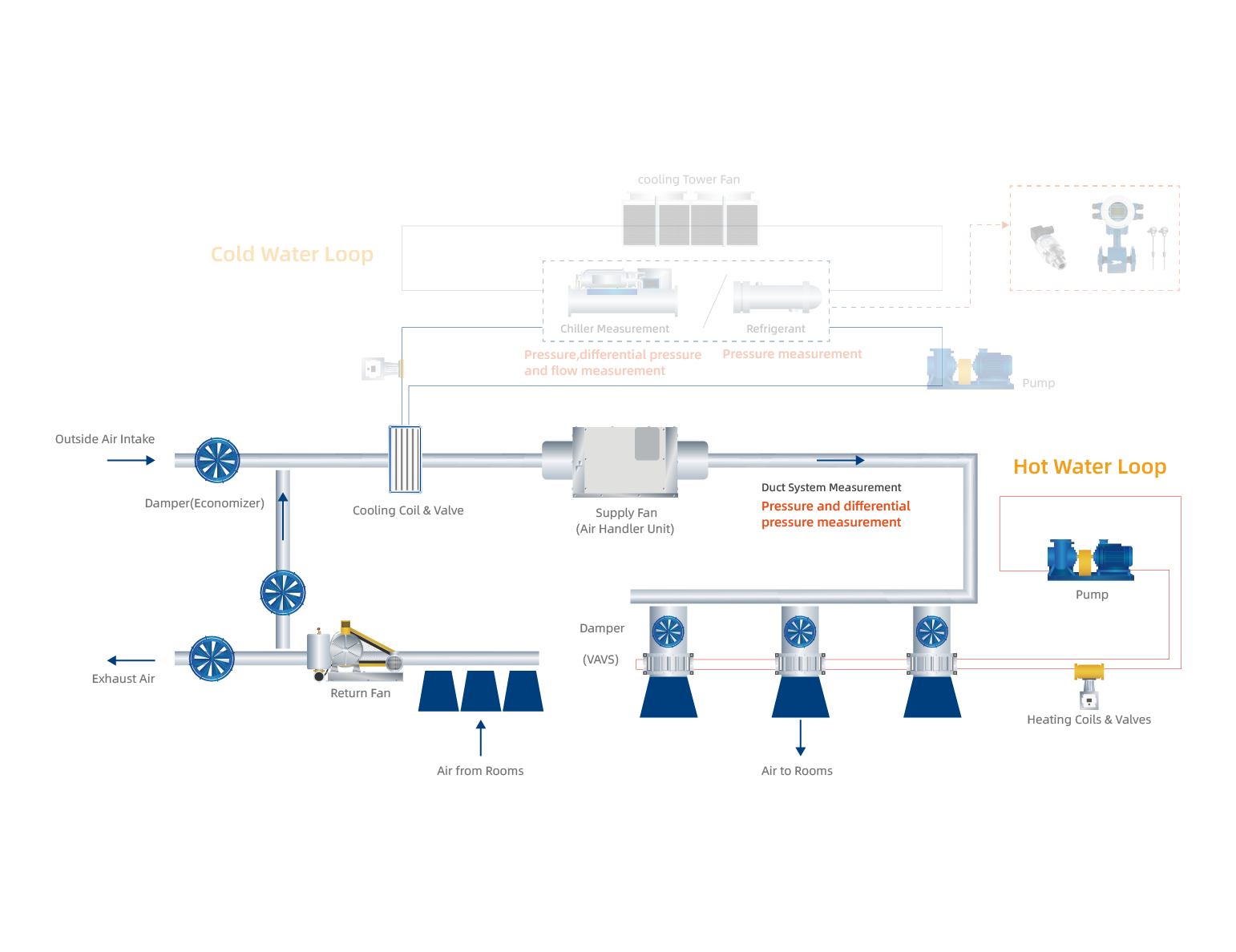

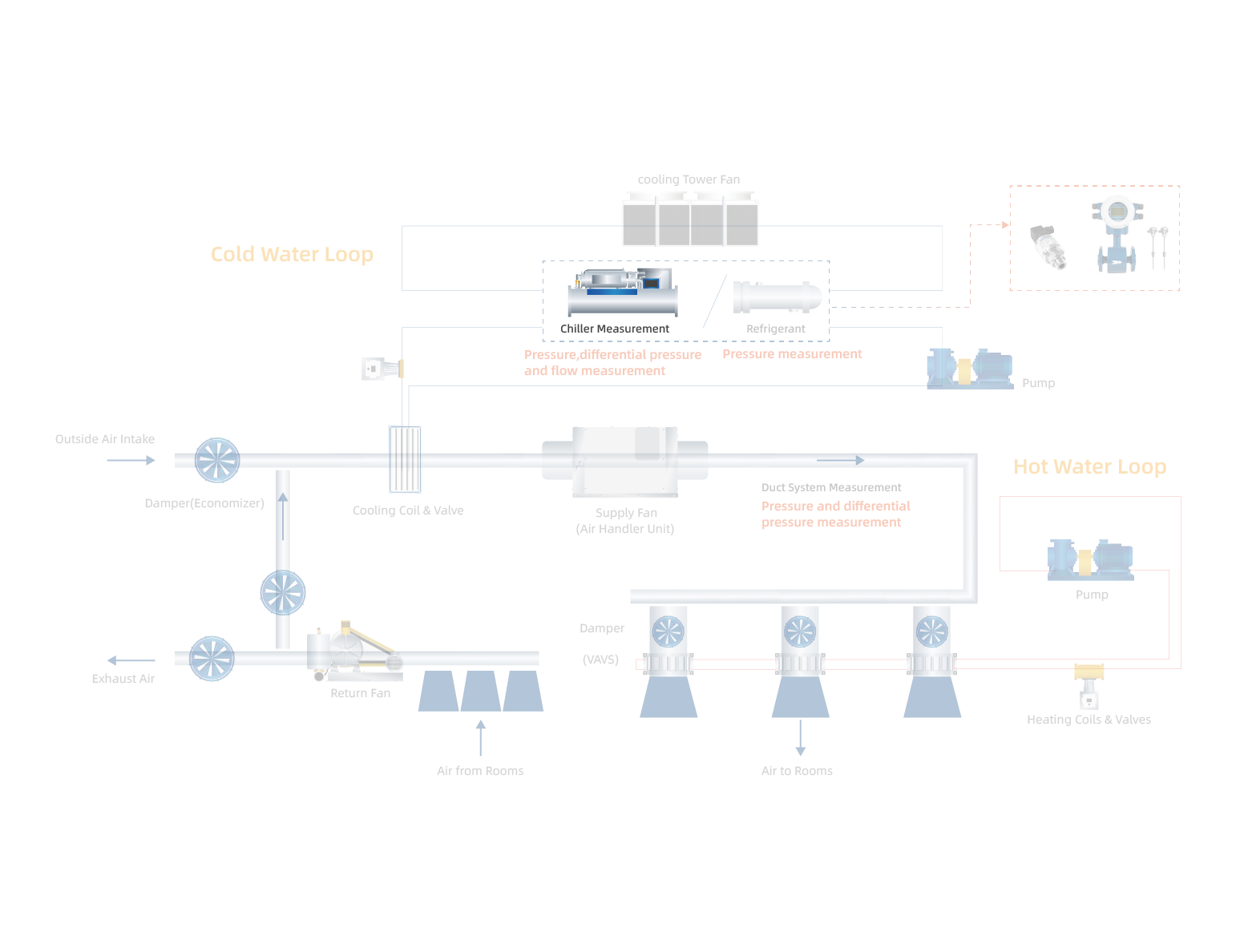

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...

In the HVAC chiller systems, measuring heat and pressure is vital for optimal performance. Pressure transmitters ensure the refrigerant operates within safe limits, while flow meters and temperature sensors calculate heat exchange efficiency. Accurate measurements enhance system reliability, and efficiency, and prevent potential failures.

more info...

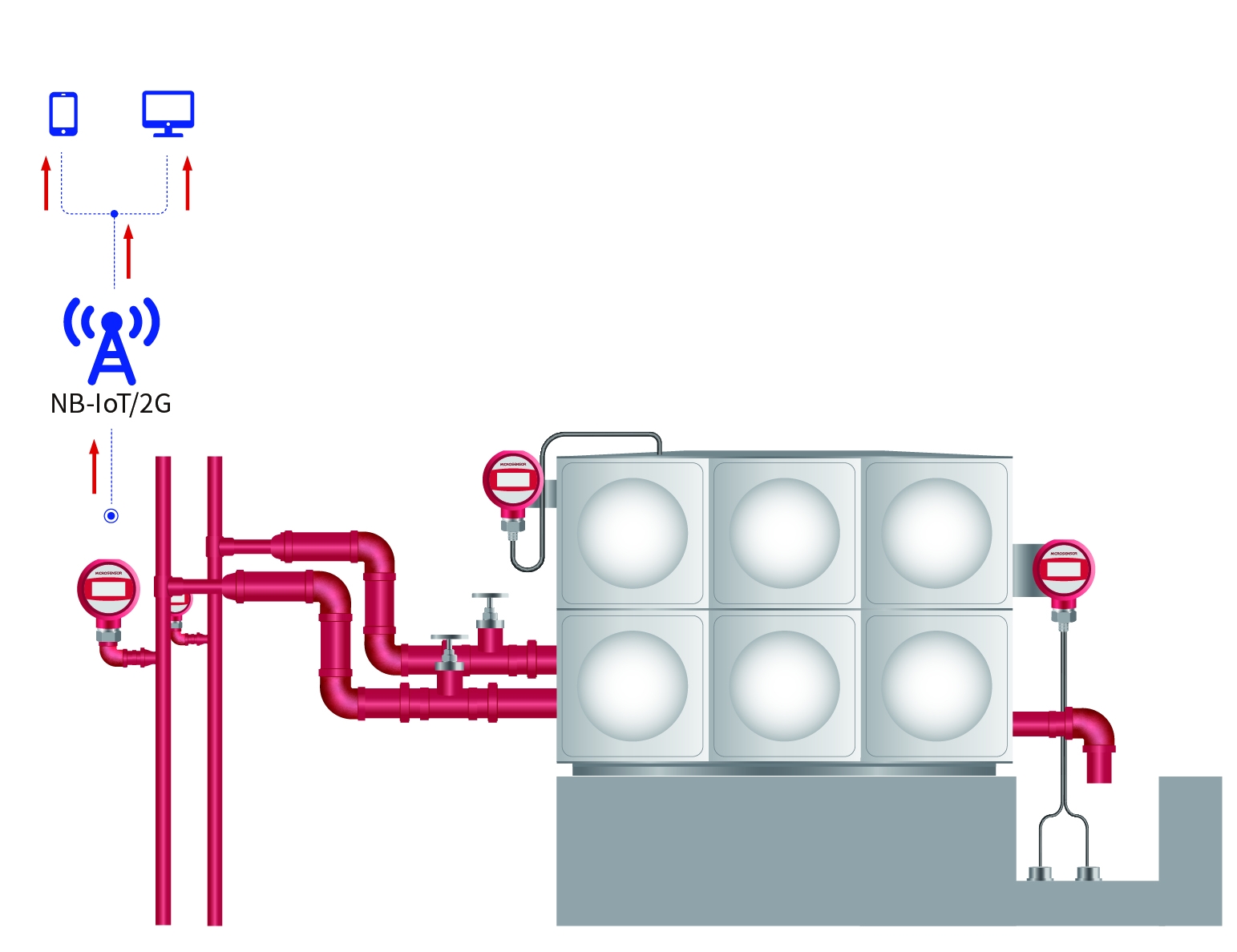

The normal operation of fire-fighting water pipeline plays an important role in safeguarding citizens' personal and property safety. Monitoring instruments are installed at each monitoring point of the fire protection pipeline to monitor pressure and level data in real time, so that when an error occurs, faults are located in time and alarms are given to facilitate staff maintenance and processing.

more info...