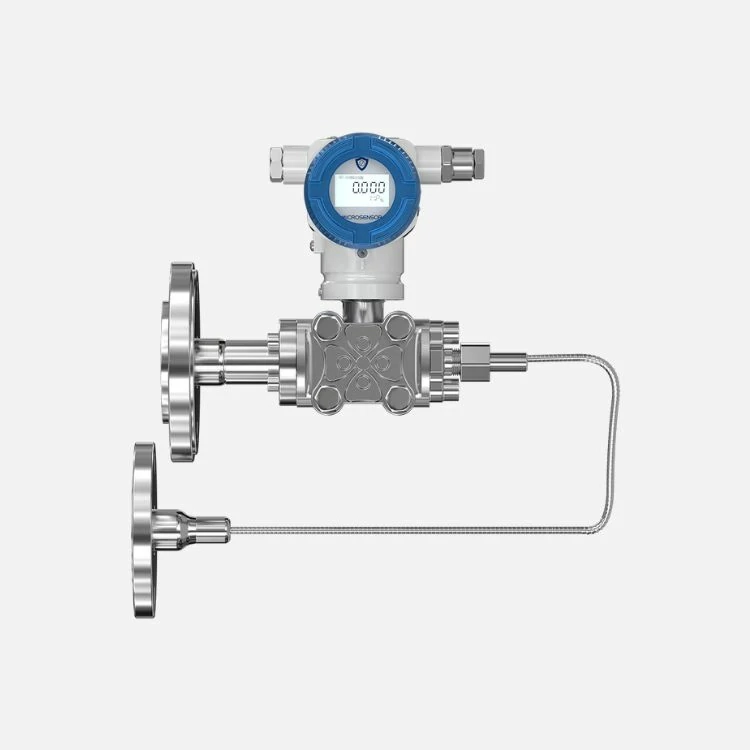

Smart Differential Pressure Transmitter With Remote Diaphragm Seal

Accuracy:±0.2% URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.2% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP/AP

Used For

Chemical, Oil and Gas, Pulp and Paper, Electric Power, Metallurgy, Energy, Food and Beverage, Medical and Health, General Process Industries

Leave a MessageMDM7000-GP/AP Smart Gauge/Absolute Pressure Transmitter has high precision and excellent long-term stability. The advanced monocrystalline piezoresistive technology enables the MDM7000-GP/AP to achieve an accuracy of 0.075%FS. The MDM7000-GP/AP offers a range of 0.4bar to 400bar (MDM7000-GP) or 0.4bar to 100bar (MDM7000-AP). The product has excellent anti-interference ability, high-frequency response ability and anti-overload ability. Digital signal processing and communication methods enable remote setup, monitoring and testing for easy production process control and maintenance.

It provides an accurate and reliable pressure measurement solution for industrial applications. MDM7000-GP/AP diaphragm pressure transmitter is a reliable pressure monitoring device for industrial process control system and chemical industry. The features of high accuracy, rugged construction and smart make the MDM7000 Series an excellent choice for any industry requiring precise pressure measurement and control.

Features

• Accuracy up to 0.075%FS

• Long-term stability: ±0.2% SPAN/10 years

• High voltage overload protection, strong anti-interference ability

• DNV, ABS, KR, NK, and RS approved for installation on vessels

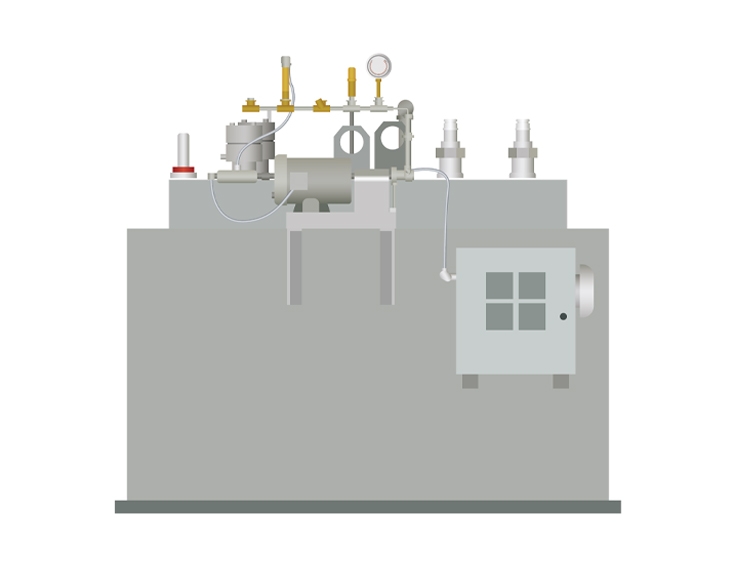

Image:

MDM7000-GP/AP Smart Gauge/Absolute Pressure Transmitter has high precision and excellent long-term stability. The advanced monocrystalline piezoresistive technology enables the MDM7000-GP/AP to achieve an accuracy of 0.075%FS. The MDM7000-GP/AP offers a range of 0.4bar to 400bar (MDM7000-GP) or 0.4bar to 100bar (MDM7000-AP). The product has excellent anti-interference ability, high-frequency response ability and anti-overload ability. Digital signal processing and communication methods enable remote setup, monitoring and testing for easy production process control and maintenance.

It provides an accurate and reliable pressure measurement solution for industrial applications. MDM7000-GP/AP diaphragm pressure transmitter is a reliable pressure monitoring device for industrial process control system and chemical industry. The features of high accuracy, rugged construction and smart make the MDM7000 Series an excellent choice for any industry requiring precise pressure measurement and control.

Features

• Accuracy up to 0.075%FS

• Long-term stability: ±0.2% SPAN/10 years

• High voltage overload protection, strong anti-interference ability

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy:±0.2% URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.2% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP Accuracy:±0.075%, ±0.1%FS, ±0.2% URL

MDM7000-AP Accuracy:±0.1%, ±0.2% URL

MDM7000-GP Range:0.4bar ~400bar

MDM7000-AP Range:0.4bar~100bar

Long-term stability:±0.2% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP-T Accuracy:±0.1%、±0.2% URL

MDM7000-AP-T Accuracy:±0.1%、±0.2% URL

MDM7000-GP-T Range:0.4bar~100bar

MDM7000-AP-T Range:0.4bar~10bar

DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.075%,±0.05%,±0.1%URL

Range: 20mbar~100bar

Long-term stability: ±0.2% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

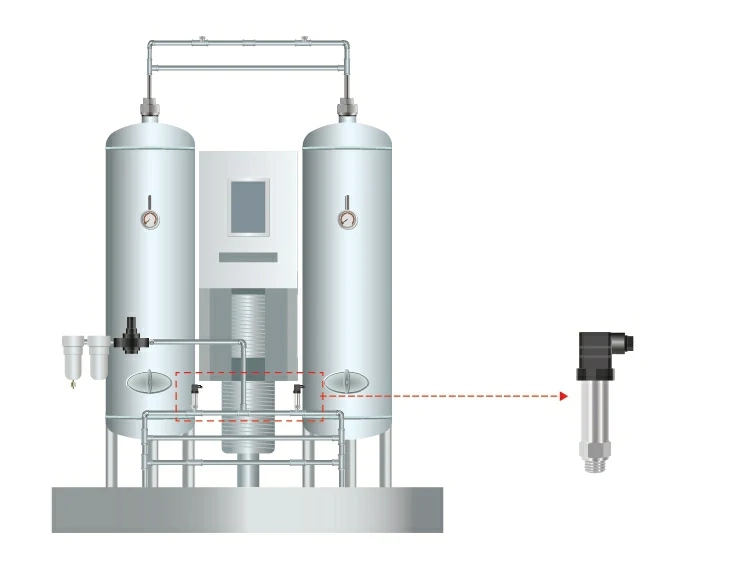

Nitrogen/oxygen generators are widely utilized in electronic equipment, medical devices, air conditioning refrigeration, and food & beverage industries. Pressure transmitters, being vital components of nitrogen/oxygen generators. They monitor the pressure within the container and throughout the variable pressure adsorption process.

more info...

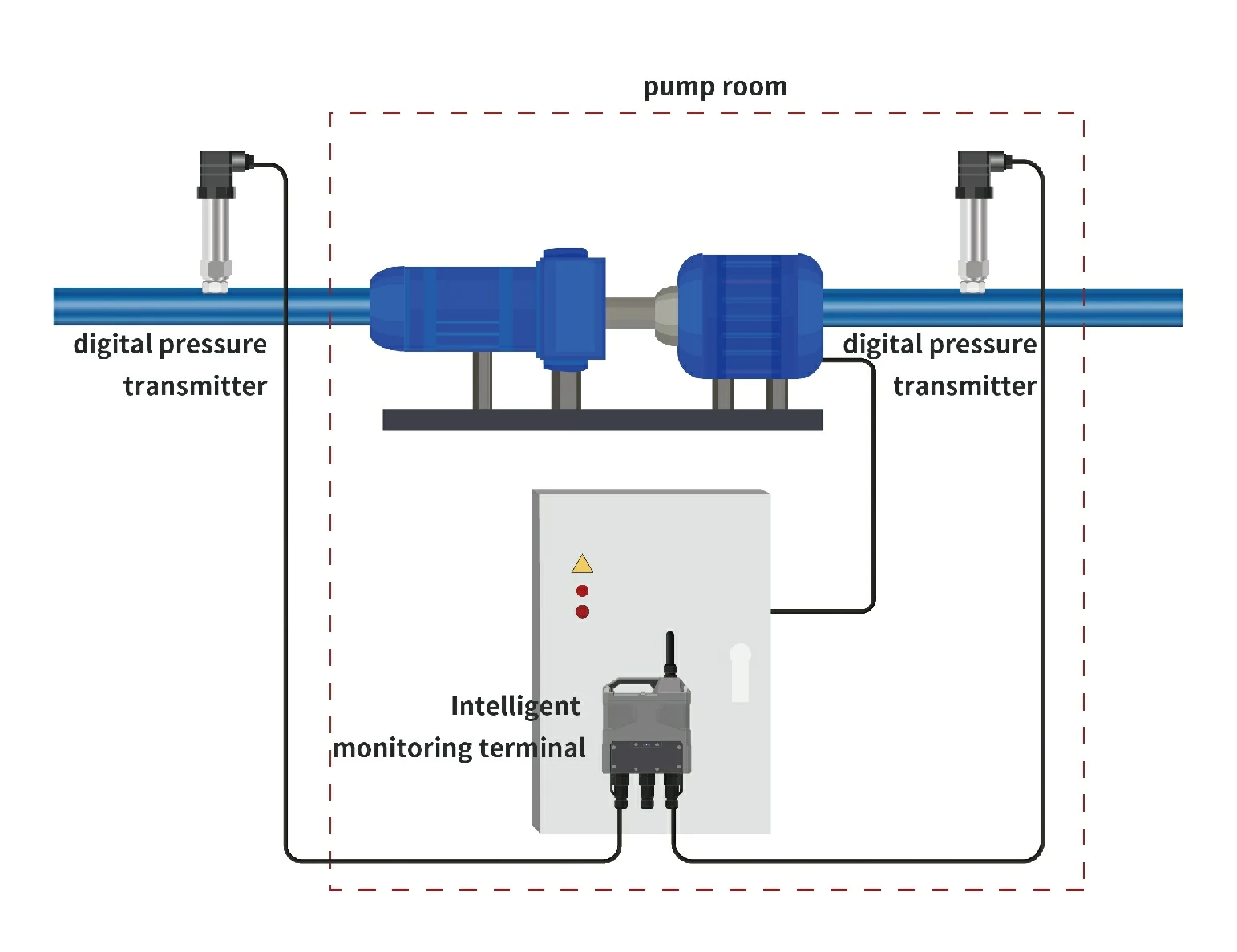

Various monitoring instruments are installed in the water storage tanks, pools, and pipelines of the water supply pump station to monitor the operation of the facilities in real-time. Through advanced cloud computing and big data technology, production data is integrated for timely alarms and early warnings.

more info...

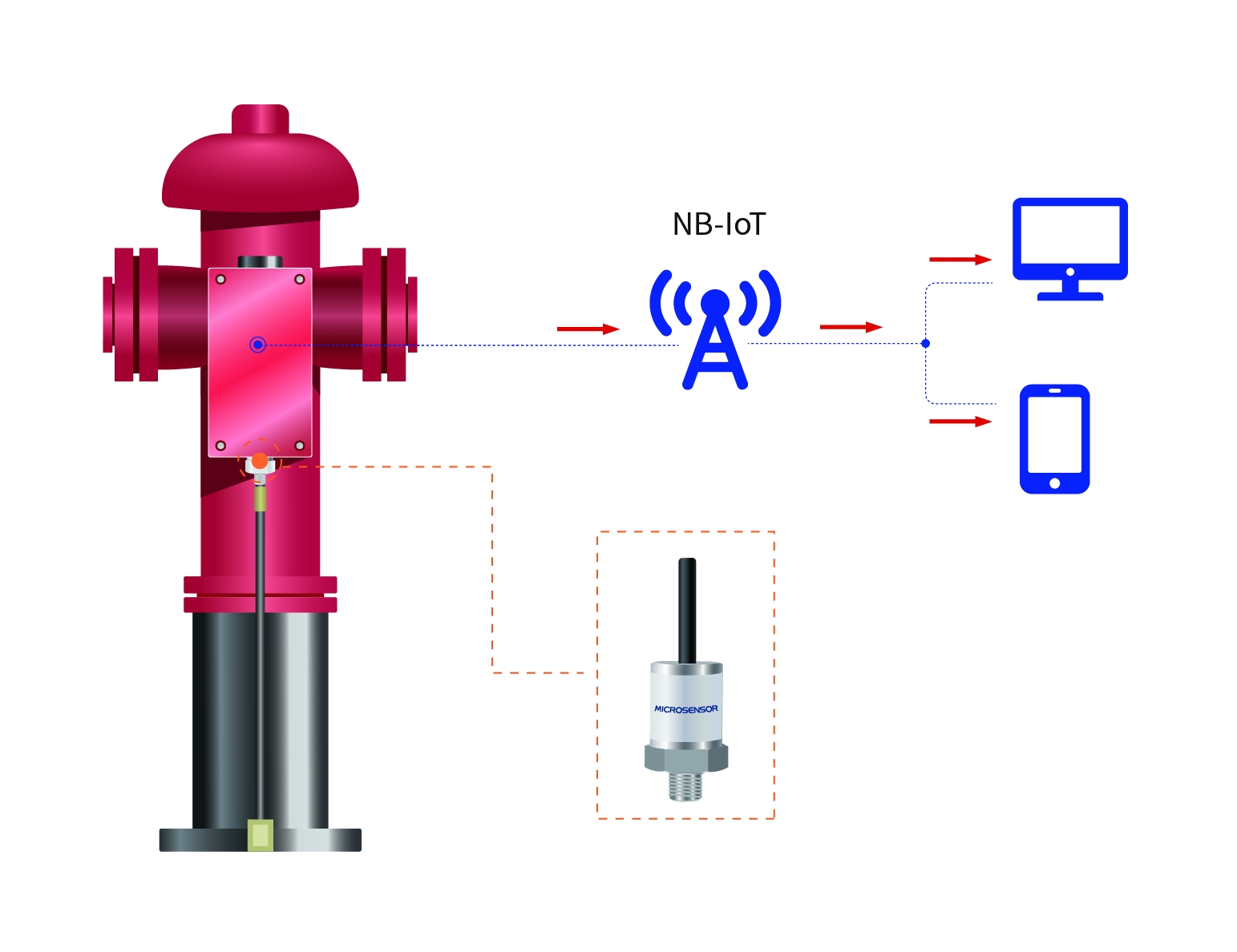

The micro-fused pressure transmitters can be used in hydrants to monitor the internal pressure of hydrants in real time, and send the data to the cloud platform for statistical analysis through wireless monitoring terminals and wireless networks. When an error occurs, it can locate the fault position and sends the alarm in time.

more info...

To ensure the fuel supply of the main engine, the separated heavy oil is first pumped to the settling tank, where the oil is heated and separated in the heating coil, and then purified by the oil separator before entering the daily tank through high-level overflow. The daily tank is directly connected to the main engine, boiler or other equipment, and the oil can be heated and used at any time.

more info...