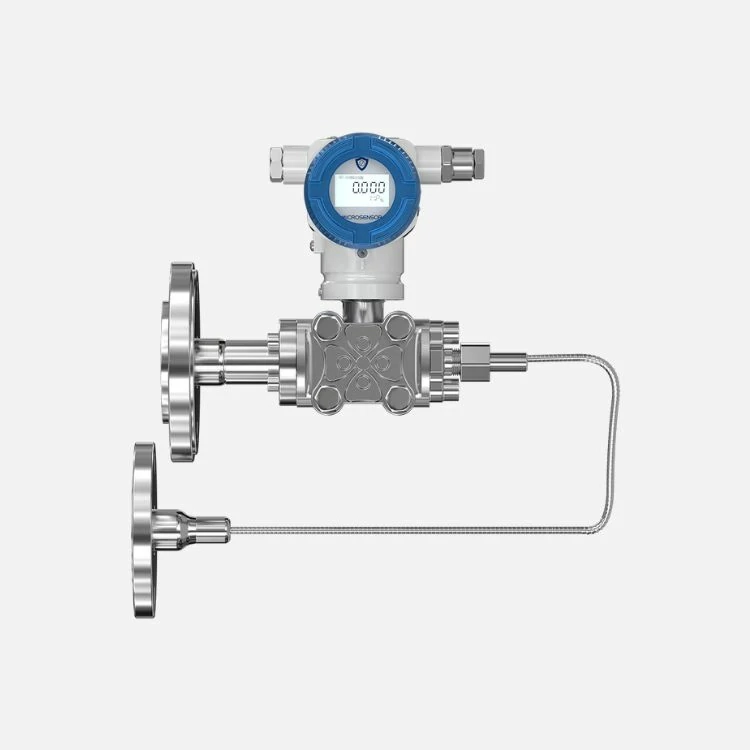

Smart Differential Pressure Transmitter With Remote Diaphragm Seal

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MDM7000DP

Used For

Oil and Gas, Food Processing, Pulp and Paper, Chemical Industry, Marine

Leave a MessageThe MDM7000DP Smart Differential Pressure Transmitter is an advanced and reliable solution for process industries. With its advanced monocrystalline silicon piezoresistance technology and high-strength housing, this transmitter offers outstanding accuracy and stability.

The accuracy of the MDM7000DP smart DP pressure transmitter is ±0.05% and ±0.075%URL. The transmitter is designed with a maximum turndown ratio of 100:1, which makes it highly flexible for adjusting the measured range. 4mA~20mA DC+HART or MODBUS RS485 signal output allows remote setting, monitoring, and testing. Additionally, the transmitter features a high-performance EMC protection circuit module with robust anti-interference capabilities. The reliable differential pressure transmitter, suitable for flow measurement and pressure measurement, is well-suited for challenging environments.

Feature

• Advanced monocrystalline silicon piezoresistive technology

• High accuracy up to 0.05%FS

• Strong anti-interference ability

• Ideal choice for the process chemical industry

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Image:

The MDM7000DP Smart Differential Pressure Transmitter is an advanced and reliable solution for process industries. With its advanced monocrystalline silicon piezoresistance technology and high-strength housing, this transmitter offers outstanding accuracy and stability.

The accuracy of the MDM7000DP smart DP pressure transmitter is ±0.05% and ±0.075%URL. The transmitter is designed with a maximum turndown ratio of 100:1, which makes it highly flexible for adjusting the measured range. 4mA~20mA DC+HART or MODBUS RS485 signal output allows remote setting, monitoring, and testing. Additionally, the transmitter features a high-performance EMC protection circuit module with robust anti-interference capabilities. The reliable differential pressure transmitter, suitable for flow measurement and pressure measurement, is well-suited for challenging environments.

Feature

• Advanced monocrystalline silicon piezoresistive technology

• High accuracy up to 0.05%FS

• Strong anti-interference ability

• Ideal choice for the process chemical industry

• DNV, ABS, KR, NK, and RS approved for installation on vessels

Accuracy: ±0.75%URL

Range: 0.4bar~2.5bar

Long-term stability: ±0.1% Span/10 years

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP Accuracy:±0.075%, ±0.1%FS, ±0.2%URL

MDM7000-AP Accuracy:±0.1%, ±0.2%URL

MDM7000-GP Range:0.4bar ~400bar

MDM7000-AP Range:0.1bar~100bar

Long-term stability:±0.1% SPAN/10years

Maximum turndown ratio:100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-GP-T Accuracy:±0.1%、±0.2%URL

MDM7000-AP-T Accuracy:±0.1%、±0.2%URL

MDM7000-GP-T Range:0.4bar~100bar

MDM7000-AP-T Range:0.4bar~10bar

DNV, ABS, KR, NK, and RS approved for installation on vessels

MDM7000-DGP Accuracy: ±0.075%, ±0.1%, ±0.2%URL

MDM7000-DAP Accuracy: ±0.1%、±0.2%URL

MDM7000-DGP Range: 60mbar ~400bar

MDM7000-DAP Range: 0.4bar~100bar

Long-term stability: ±0.1% SPAN/10 years

Maximum turndown ratio: 100:1

DNV, ABS, KR, NK, and RS approved for installation on vessels

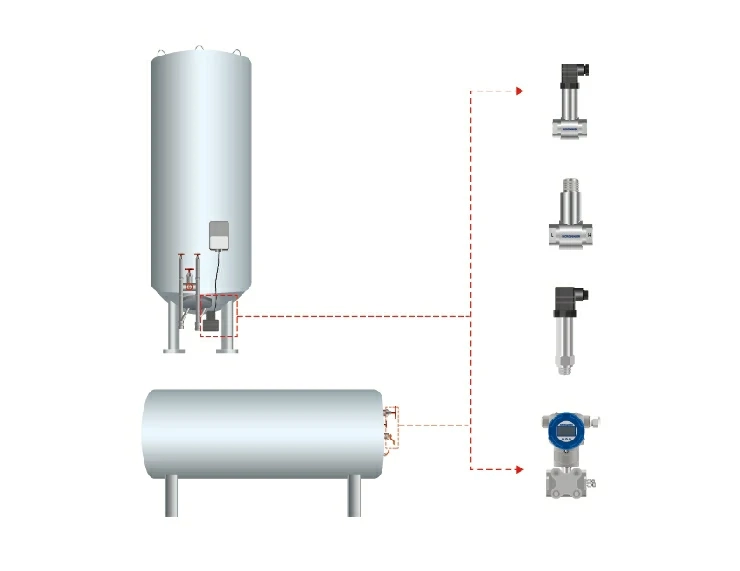

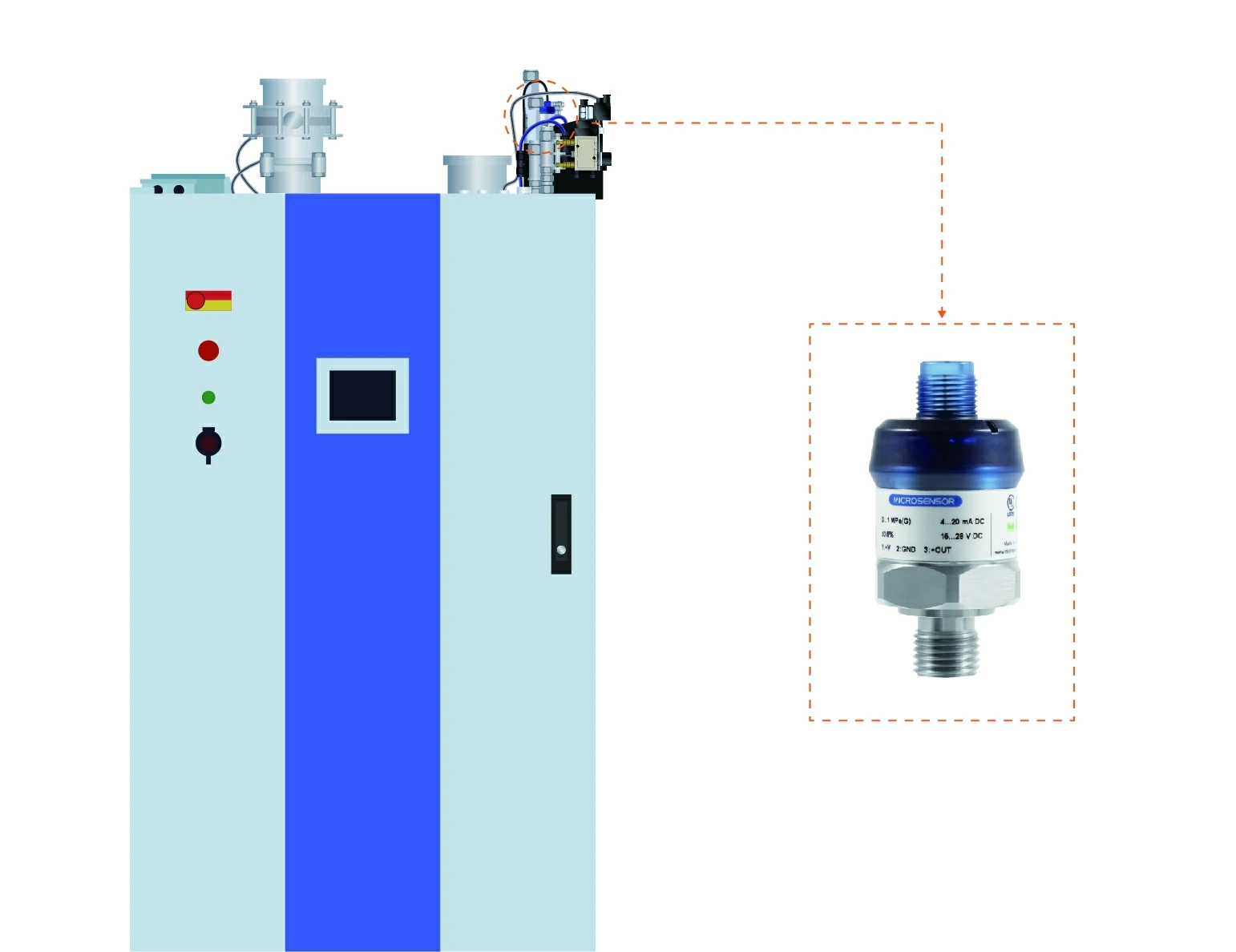

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

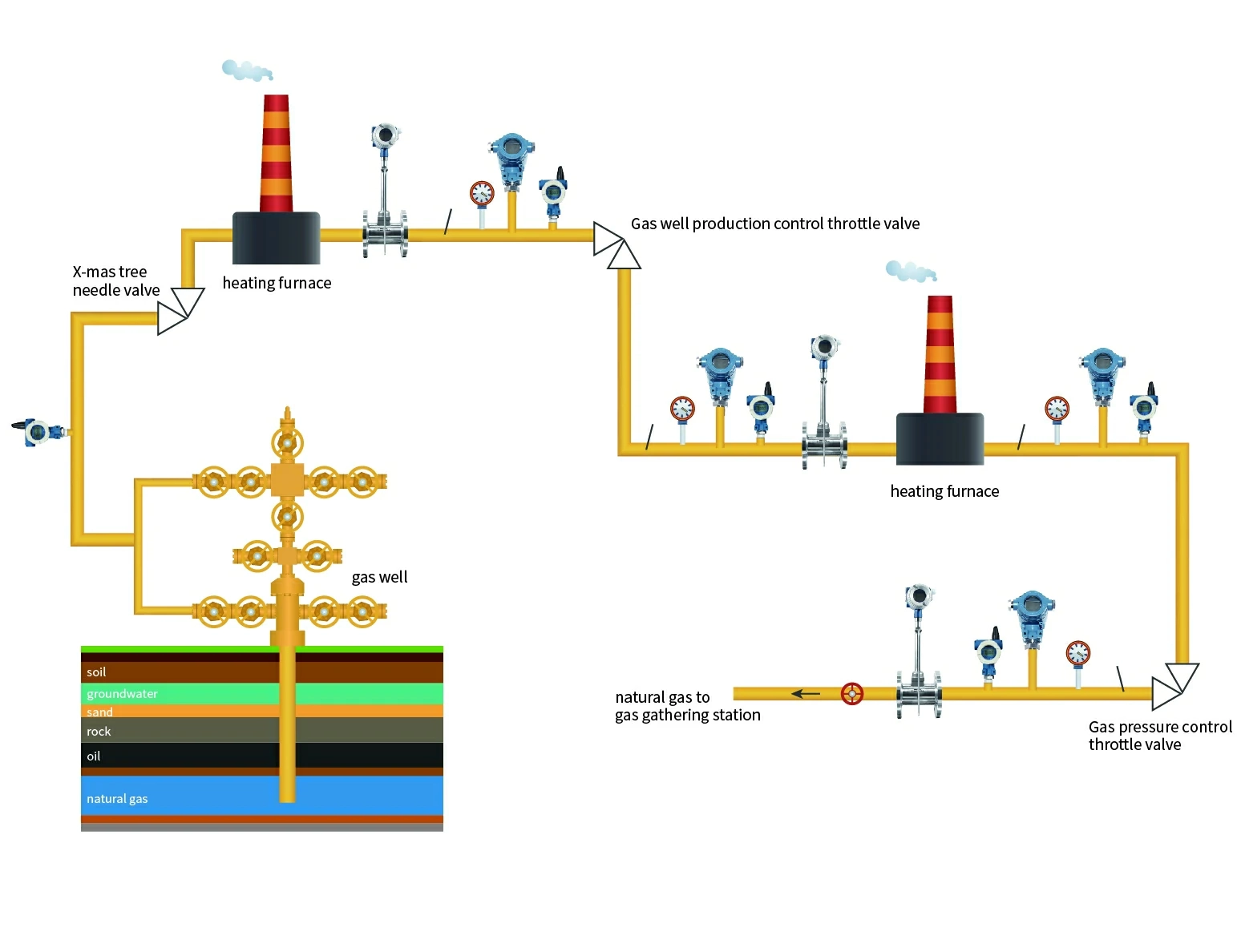

Centralizing the oil and gas produced by scattered oil wells, processing and initial processing, and exporting it after meeting the standards. The process requires multiple steps, including oil and gas separation, crude oil dehydration, and natural gas purification, thus requiring various instruments to measure production parameters.

more info...

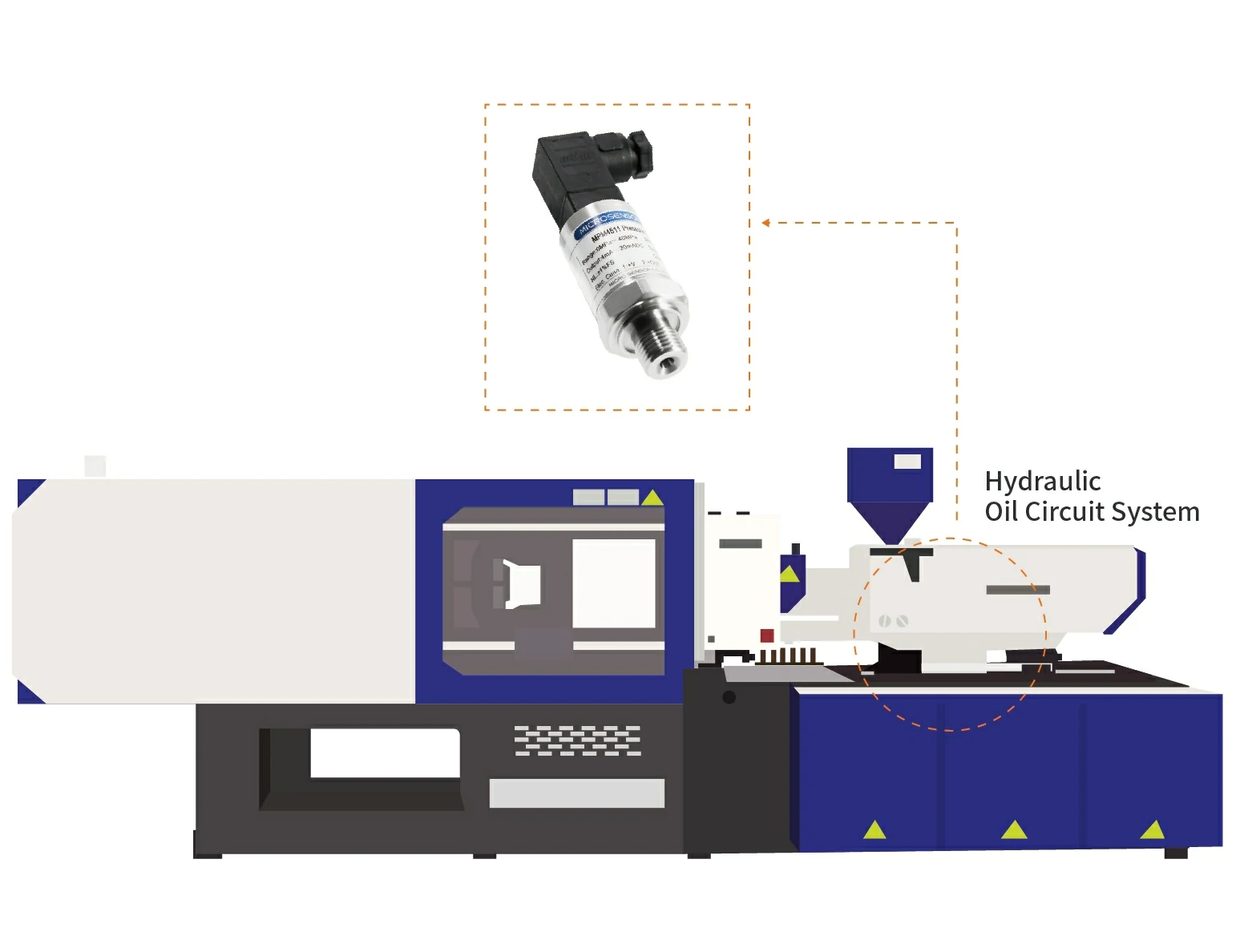

With the pressure transmitter, the pressure value of the hydraulic oil circuit system of the injection molding machine is monitored in real time, so as to provide reliable closed-loop control feedback signals for the stable operation of the hydraulic system.

more info...

The plasma in a plasma cleaning machine is a state of matter, usually composed of process gases. Therefore, specially designed pressure transmitters must be installed in the relevant gas circuits of the plasma cleaning system to monitor and provide feedback on production data.

more info...