Industry Background

Shipping is the primary mode of global trade, accounting for over 80% of the world's trade volume. As international trade continues to grow, the scale of the shipping market is also expanding.

With the application of new materials, new energy, and intelligent technology, the performance of vessels has seen significant advancements. The integration of low-carbon, clean energy sources in lieu of traditional fuels has reduced the environmental impact of vessel emissions. This, in turn, has imposed more stringent demands on pressure transmitters for the monitoring of pressure and level in various vessel operational systems.

· Vibration, High Humidity and High Salt Environment Resistance

· Flammable and Explosive Hazards

· Corrosive Media Measurement

· Strict Type Approval Certificate Requirements

Application Systems

Shipbuilding is at the heart of the maritime industry. Typically, vessels are equipped with extensive control systems, such as fuel supply system, ballast water management system, and vessel exhaust gas desulfurization and denitrification system. Based on operational requirements, there is a professional measurement need for pipeline pressure and cargo hold levels.

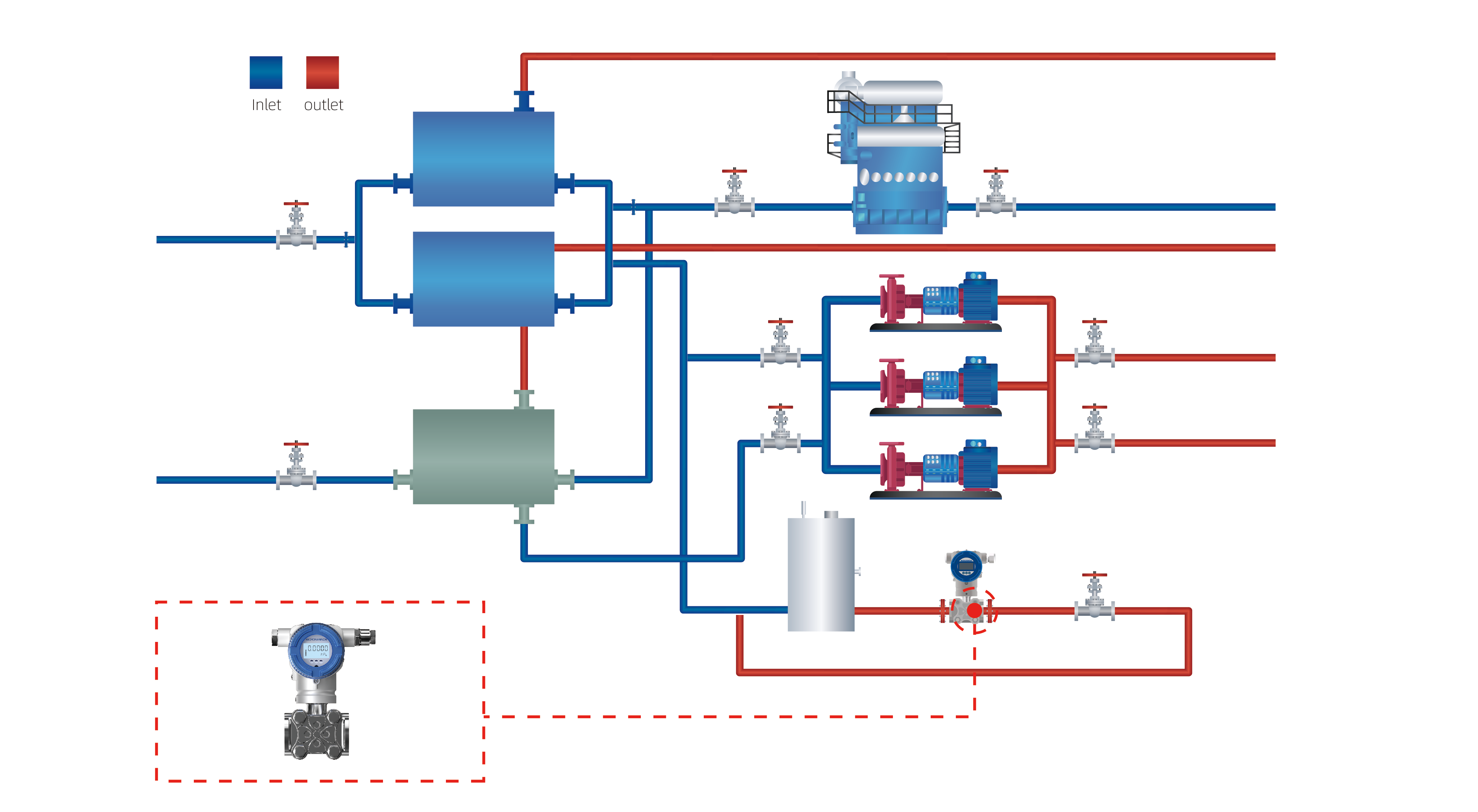

Fuel Supply System

· System Overview

The marine LNG fuel gas supply system vaporizes, heats, and pressurizes the stored liquefied natural gas onboard, providing timely and metered supply to the main engine or other gas-consuming equipment on the vessel. The fuel tank monitoring system monitors the pressure, temperature, and level of the fuel tank to ensure the overall safety management of the gas fuel system. In the LNG refueling station, the filling and vapor return pipelines require the installation of pressure transmitters and temperature gauges to provide real-time monitoring of the pressure within the pipelines. Within the LNG vaporization/heating system, the vaporizer, along with the gas buffer tank, booster pump, safety valve, low-temperature shut-off valve, pressure transmitters, and temperature gauges, are integrated into a gas-tight enclosure to form the vaporizer skid.

· Application Solutions

In the challenging conditions of ship navigation, where vibrations from equipment operation may occur, it is crucial to precisely measure the fuel consumption in the fuel supply system. The Micro Sensor smart pressure transmitter utilizes second-generation monocrystalline silicon compound sensor technology and advanced MCU neural network algorithms. It undergoes network compensation with multiple temperature and pressure points to mitigate the impact of vibrations to less than 0.1%, ensuring accurate measurements within ±0.075% F.S. Also, when combined with Micro Sensor-designed mounting brackets, the detrimental effects of vibrations on pipeline pressure measurements are significantly reduced.

Potential fuel leakage issues in fuel tanks and pipelines necessitate a safe and explosion-proof pressure sensor for real-time pressure monitoring. Micro Sensor smart pressure sensor fully complies with domestic and international explosion-proof standards, and has obtained the Chinese certificates PCEC and NEPSI, as well as international certificates such as ATEX, IECEx, and CSA.

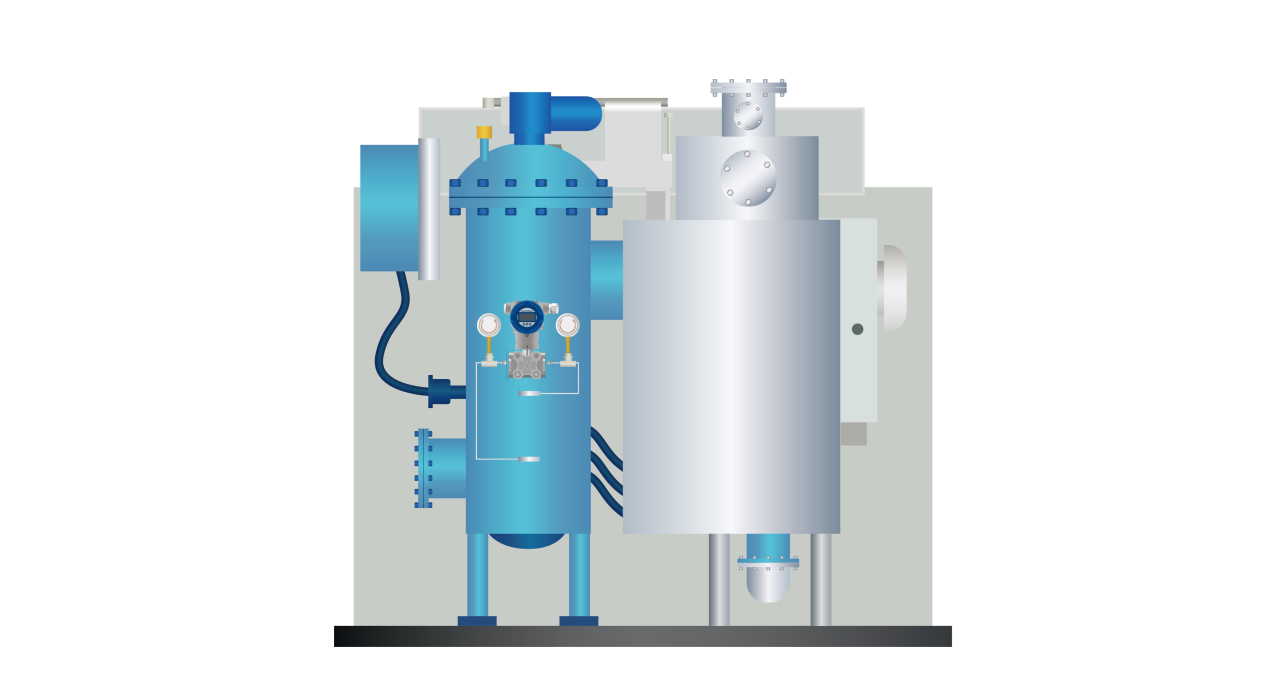

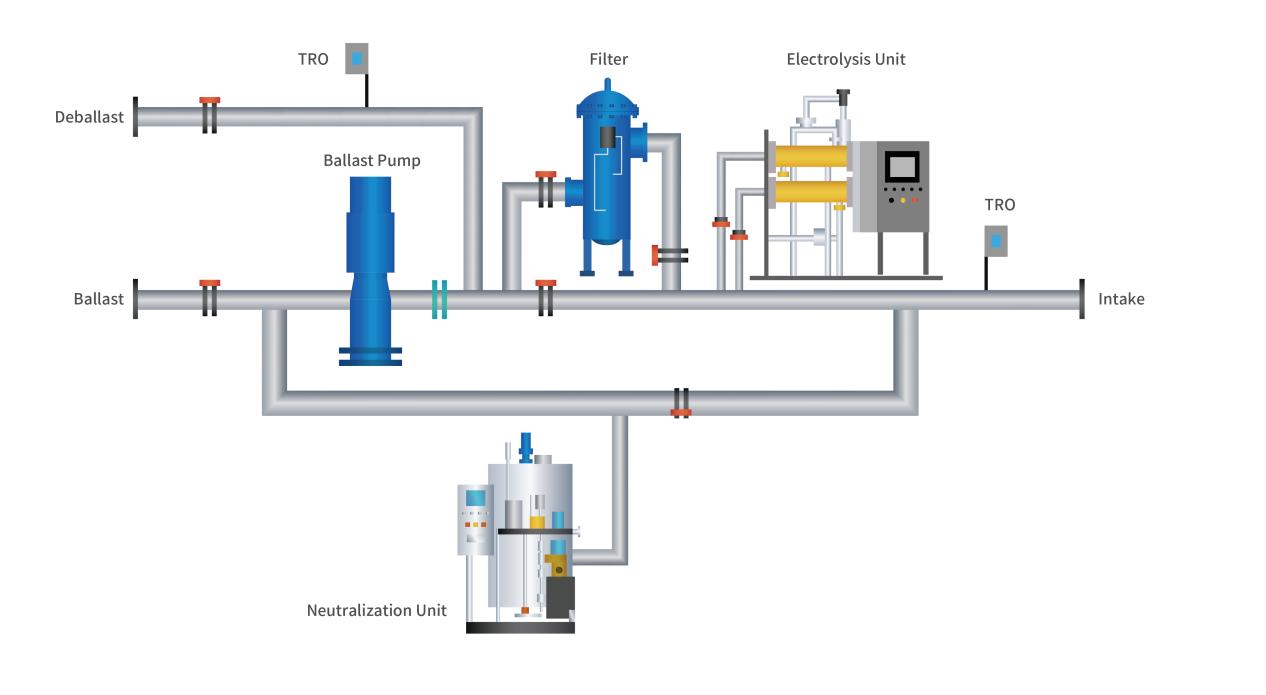

Ballast Water Management System

· System Overview

The Ballast Water Management System on ships is utilized for treating ballast water discharged into the sea. This system comprises a control unit, filters, ballast water pumps, ballast water pipelines, ballast tanks, and relevant valves. The system requires measurements of inlet flow rate, tank level, and system pressure. Given that ships operate in harsh environments such as seawater and river water for extended periods, leading to seawater corrosion and dampness in compartments, pressure transmitters installed on pipelines and tanks must mitigate the influences of marine microorganisms and sediment on pressure measurements.

· Application Solutions

The Micro Sensor's pressure transmitter with dual diaphragms is designed to address the specific operational requirements on ships, effectively addressing issues commonly encountered on vessels, such as seawater condensation, splashing, and salt mist crystallization. Furthermore, the smart pressure transmitters from Micro Sensor feature an IP67, have undergone WF2 anti-corrosion testing, and can provide various anti-corrosive diaphragms such as Hastelloy C and Tantalum. The products are housed in a 316 stainless steel shell and have obtained Type Approval Certificates from 8 countries, including DNV, RS, and CCS, thereby delivering a safe, reliable, and professional pressure measurement solution to the maritime industry clients.

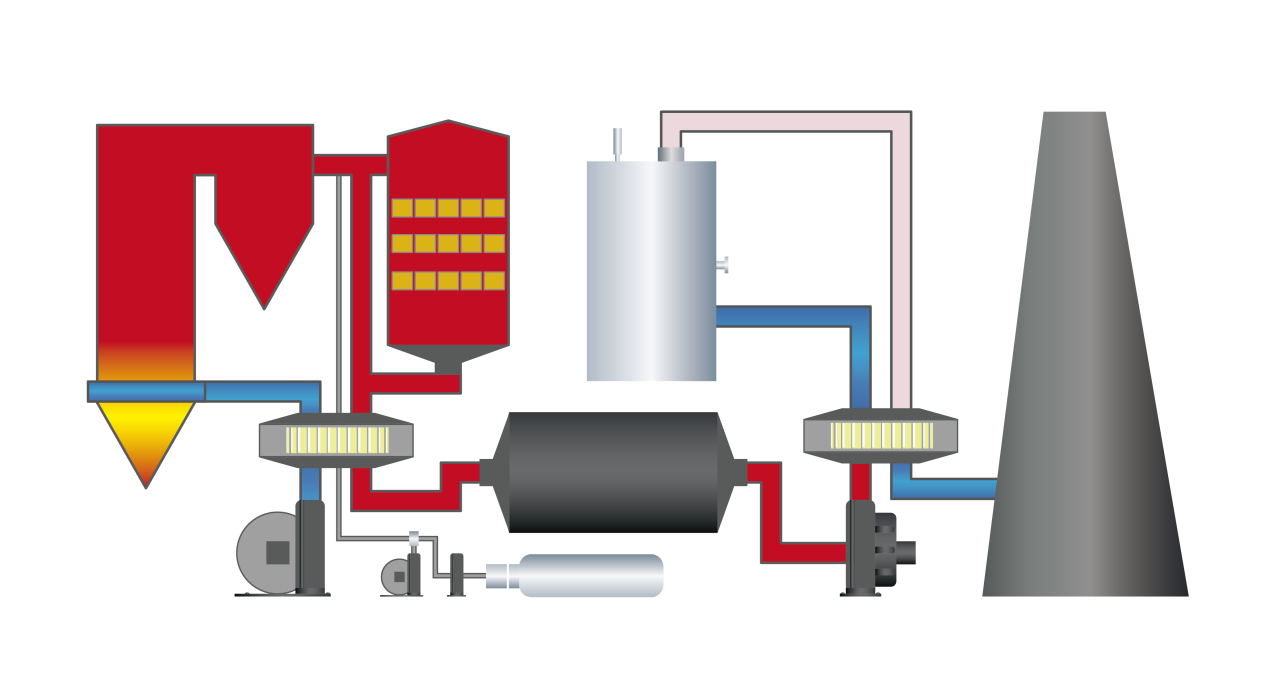

Vessel Exhaust Gas Desulfurization and Denitrification System

· System Overview

The ship exhaust gas treatment system primarily consists of two subsystems: denitrification and desulfurization. It utilizes multiple sensors (pressure, temperature, flow, etc.) to gather essential parameters during operations, enabling intelligent control of the entire system.

Ship desulfurization tower is commonly installed on the main engine and generator exhaust pipes to eliminate sulfides and particulate matter from the exhaust gas. Ship exhaust gas denitrification system employs the selective catalytic reduction method and primarily comprises a catalytic reactor, urea supply unit, urea injection unit, and distribution control system.

· Application Solutions

1. In ship exhaust gas treatment, equipment such as scrubbing towers and fan ducts operate at elevated temperatures, necessitating transmitters capable of measuring pressure in high-temperature environments. Micro Sensor offers a dual-fill liquid diaphragm seal system that can measure pressures in high-temperature conditions, equipped with high-temperature-resistant silicone oil to achieve stable on-site pressure monitoring.

2. In the ship exhaust gas desulfurization and denitrification treatment system, seawater washing and various chemical media will cause corrosion to the pressure measurement products. Micro Sensor provides corrosion-resistant stainless steel housings, offering 316L, HC-276, tantalum, titanium, and other corrosion-resistant diaphragms. Additionally, various corrosion-resistant treatment processes such as diaphragm plating, spraying, and PFA coating are available to fully meet the pressure measurement requirements in the harsh maritime condition.

Application Cases

|  |

(Left Image: Pressure Measurement of LNG Fuel Vacuum Insulation System; Right Image: Differential Pressure Measurement of Sea Water Inlet and Outlet for Ship Generator Cooling System)

Recommended Products

(MDM7000 Smart Pressure Transmitter)

Features

• Adopting second-generation monocrystalline silicon compound sensor technology, with automated core encapsulation, temperature-pressure fully automated compensation calibration, and verification reports provided for each unit upon leaving the factory.

• Holds Type Approval Certificates from 8 countries including DNV, CCS, RS, NK, ABS, BV, KR, and LR to meet the maritime product requirements of clients worldwide.

• The products meet the requirements of Chinese explosion-proof certificates such as PCEC and NEPSI and international explosion-proof certificates such as ATEX, IECEx and CSA.

• Standard accuracy: ±0.075%FS, ±0.05%FS

• Long-term stability: ±0.1% SPAN/5 years

• Offers various housing options for diverse conditions: aluminum alloy, stainless steel, low copper-zinc.

• Designed with a modular construction, dual-chamber design, with IP67 protection rating, resulting in low operational costs.

• Maximum static pressure: 420 bar

• Low temperature LCD: -40℃-70℃

• Excellent EMC performance, with CE and ROSH certificates.

• Provides a variety of pressure process connection specifications and electrical connection specifications to adapt to different on-site operational conditions.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD