Temperature Transmitter

CE, CNEX, CCS, DNV, ABS approved

Available for customization

Temperature Ranges: -200℃ …0℃~1200℃

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MW7000

Used For

Clean the measuring flange diaphragm.

Leave a MessageIntroduction

The flushing ring is a component of fluid piping systems installed between instrumentation and pipelines. Its primary function is to clean the measuring flange diaphragm, preventing errors caused by the attachment of liquid or impurities, thereby enhancing the accuracy and reliability of the transmitter. It facilitates fluid flushing, cleaning, and draining functions to ensure a favorable medium environment on the instrument diaphragm surface. The MW7000 flushing ring catalog includes flushing ring and flushing ring with mounted valve(s).

Functions

• Flushing ring

Equipped with open/closed flushing bores (with plug screws) to facilitate inlet and outlet of flushing media.

• Flushing ring with mounted valve

Equipped with open/closed flushing bores (with plug screws) to selectively allow or block internal media output.

The inlet side is fitted with a manual valve to regulate the flow of flushing media by adjusting the valve opening, to accommodate flushing requirements.

• Flushing ring with mounted valves

Equipped with manual valves at both inlet and outlet sides to regulate the flow of flushing media at both sides by adjusting the valve opening, to accommodate flushing requirements.

Image:

Introduction

The flushing ring is a component of fluid piping systems installed between instrumentation and pipelines. Its primary function is to clean the measuring flange diaphragm, preventing errors caused by the attachment of liquid or impurities, thereby enhancing the accuracy and reliability of the transmitter. It facilitates fluid flushing, cleaning, and draining functions to ensure a favorable medium environment on the instrument diaphragm surface. The MW7000 flushing ring catalog includes flushing ring and flushing ring with mounted valve(s).

Functions

• Flushing ring

Equipped with open/closed flushing bores (with plug screws) to facilitate inlet and outlet of flushing media.

• Flushing ring with mounted valve

Equipped with open/closed flushing bores (with plug screws) to selectively allow or block internal media output.

The inlet side is fitted with a manual valve to regulate the flow of flushing media by adjusting the valve opening, to accommodate flushing requirements.

• Flushing ring with mounted valves

Equipped with manual valves at both inlet and outlet sides to regulate the flow of flushing media at both sides by adjusting the valve opening, to accommodate flushing requirements.

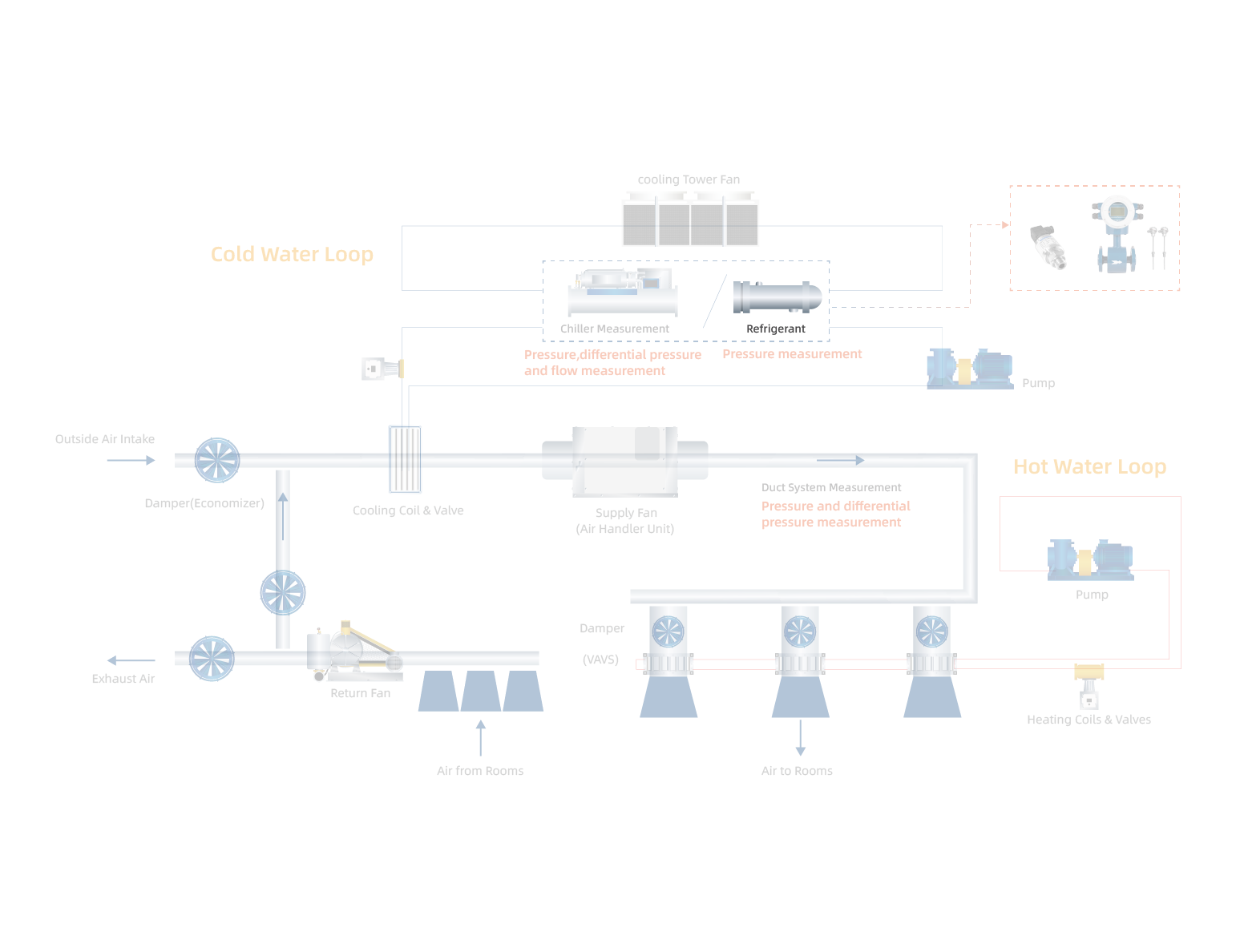

In HVAC systems, measuring the pressure of refrigerants is critical. Pressure transmitters monitor the refrigerant's pressure to ensure it operates within safe limits, preventing leaks and system failures. Accurate pressure measurement enhances system efficiency, ensures optimal cooling performance, and maintains safety by detecting potential issues early

more info...

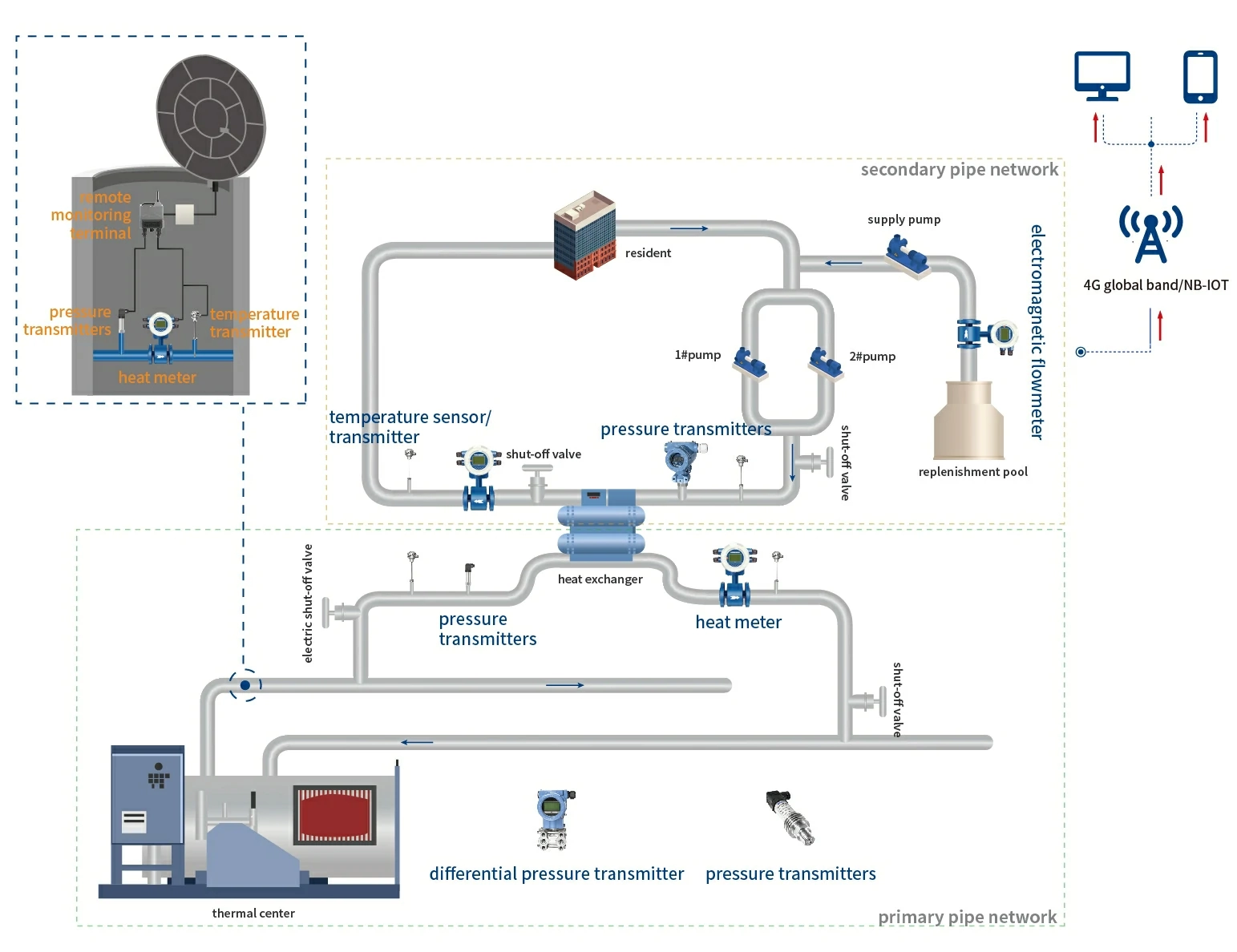

Electromagnetic flowmeters, ultrasonic flowmeters, level transmitters, pressure transmitters are installed in the heat exchange station heating system to obtain real-time data on pipeline flow, heat, temperature, and pressure, ensuring the normal operation of the heat exchange station.

more info...

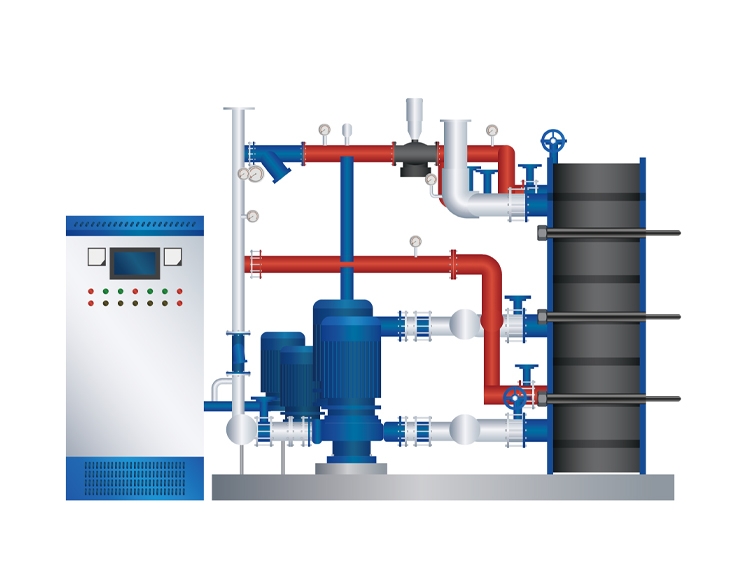

The marine temperature control system uses a refrigerant circulating between the condenser and evaporator to achieve cooling, heating, and dehumidification.

more info...

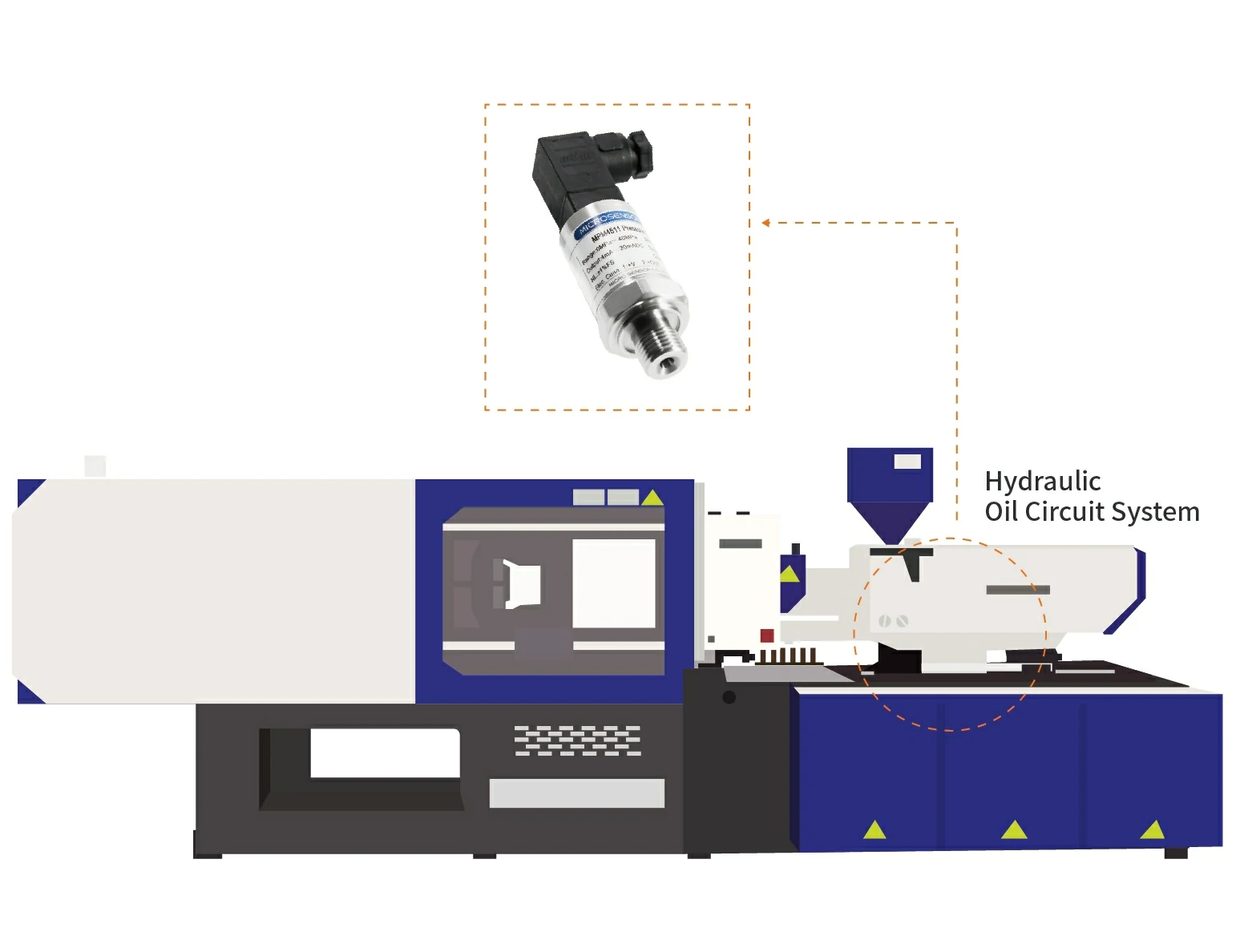

With the pressure transmitter, the pressure value of the hydraulic oil circuit system of the injection molding machine is monitored in real time, so as to provide reliable closed-loop control feedback signals for the stable operation of the hydraulic system.

more info...