Digital RS485 HART Pressure Transmitter

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4760

Used For

Precise Measurement of Flowing Pressure

Leave a MessageThe high-precision, high-stability MPM4760 intelligent display pressure transmitter is digital display pressure gauge. The pressure transducer with display can be used for precision pressure measurement and control. The product circuit and program algorithm are upgraded, which improves the test accuracy. In the compensation temperature range, the typical error of the whole temperature zone is better than 0.1%. The optimization of battery-powered power consumption makes battery life greater than 3 years. The number of LCD display digits is increased to four and a half digits, and the backlight is increased.

Features

• Various interfaces are optional

• Battery powered

• Wider temperature compensation range

• Optional data display

Specifications

• Measure range: -1bar...0bar~0.1bar…1000bar

• Overpressure: 1.5 times FS or 1100bar(Take the minimum value)

• Total Accuracy: ±0.25%FS

• Stability: ±0.2%FS/Year

• Compensated Temp.: -10℃~70℃

• Working Temp.: -30℃~80℃

• Storage Temp.: -40℃~85℃

• Power Supply : 8V~28V DC or Battery supply

• Output signal: Standard analog 4mA~20mA DC, 2-wire;digital RS485 interface

• Battery supply with RS485 output: digital RS485 interface

• RS485 interface: ASCII agreement or MODBUS RTU,BUS with 99 transmitters

Image:

The high-precision, high-stability MPM4760 intelligent display pressure transmitter is digital display pressure gauge. The pressure transducer with display can be used for precision pressure measurement and control. The product circuit and program algorithm are upgraded, which improves the test accuracy. In the compensation temperature range, the typical error of the whole temperature zone is better than 0.1%. The optimization of battery-powered power consumption makes battery life greater than 3 years. The number of LCD display digits is increased to four and a half digits, and the backlight is increased.

Features

• Various interfaces are optional

• Battery powered

• Wider temperature compensation range

• Optional data display

Specifications

• Measure range: -1bar...0bar~0.1bar…1000bar

• Overpressure: 1.5 times FS or 1100bar(Take the minimum value)

• Total Accuracy: ±0.25%FS

• Stability: ±0.2%FS/Year

• Compensated Temp.: -10℃~70℃

• Working Temp.: -30℃~80℃

• Storage Temp.: -40℃~85℃

• Power Supply : 8V~28V DC or Battery supply

• Output signal: Standard analog 4mA~20mA DC, 2-wire;digital RS485 interface

• Battery supply with RS485 output: digital RS485 interface

• RS485 interface: ASCII agreement or MODBUS RTU,BUS with 99 transmitters

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Low Power Consumption

Range: -1bar…0bar ~ 0.1bar…1000bar

Digital temperature compensation and non-linearity modulation

High-level electromagnetic compatibility

Support reverse polarity, transient overcurrent and over-voltage protection

LCD / LED display

CE approved

LCD display Corrosion-resistant housing

High accuracy ±0.1% FS

High level EMC protection

Simultaneous hybrid output of 4-20 mA+RS485

Intrinsically safe and explosion proof certification

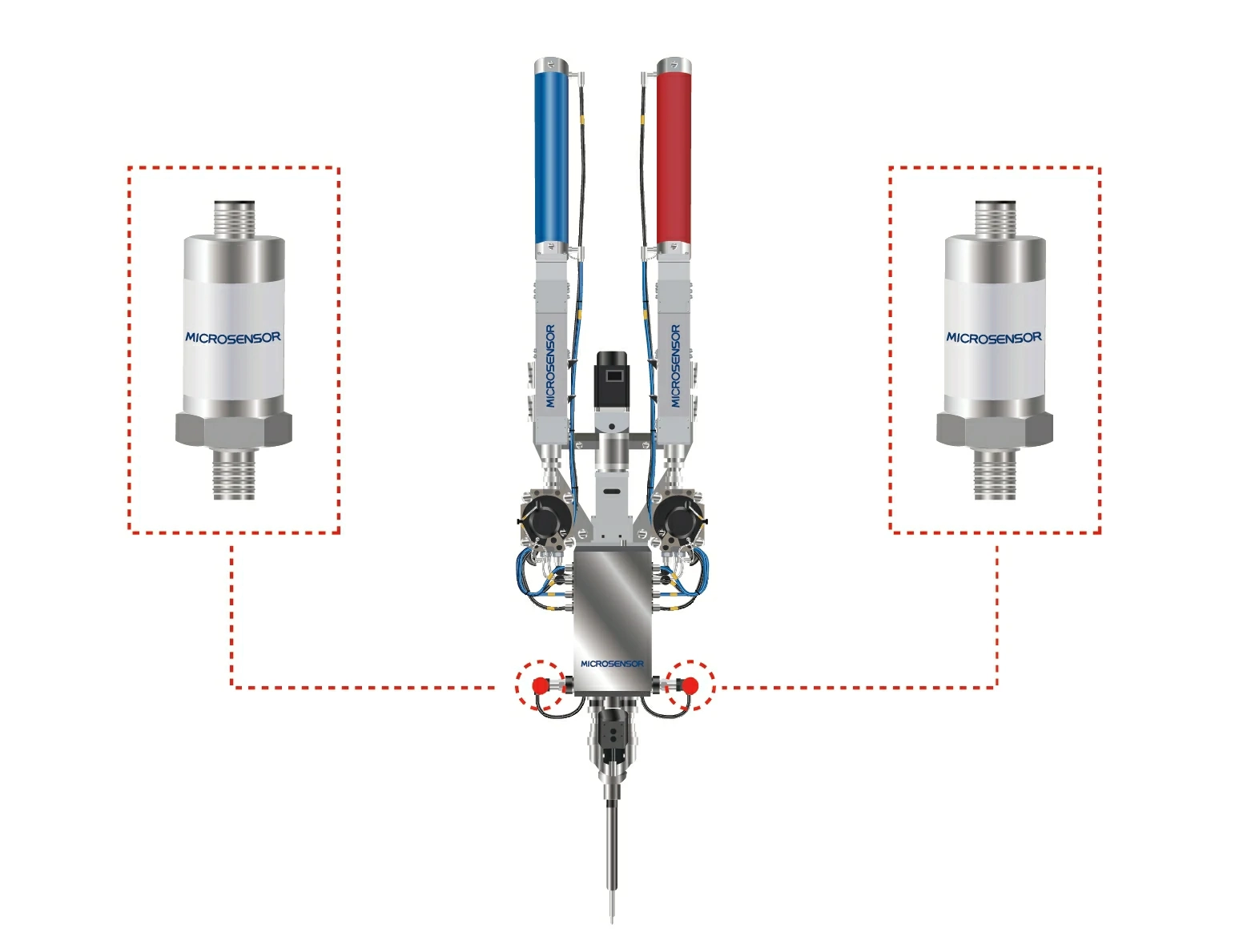

Dispensing machine is used to control adhesive, paint and other liquids. It requires compressed air to be fed into the glue bottle for proper operation. The role of the pressure transmitter is to monitor the pressure at the air inlet to ensure that the dispenser works properly.

more info...

Perfect coffee needs pressure. Water and steam pressure monitoring of the coffee machine ensures safe and high-quality coffee production. Accurately measuring pressure is required during the coffee bean extraction, hot water delivery, and cleaning of coffee machines.

more info...

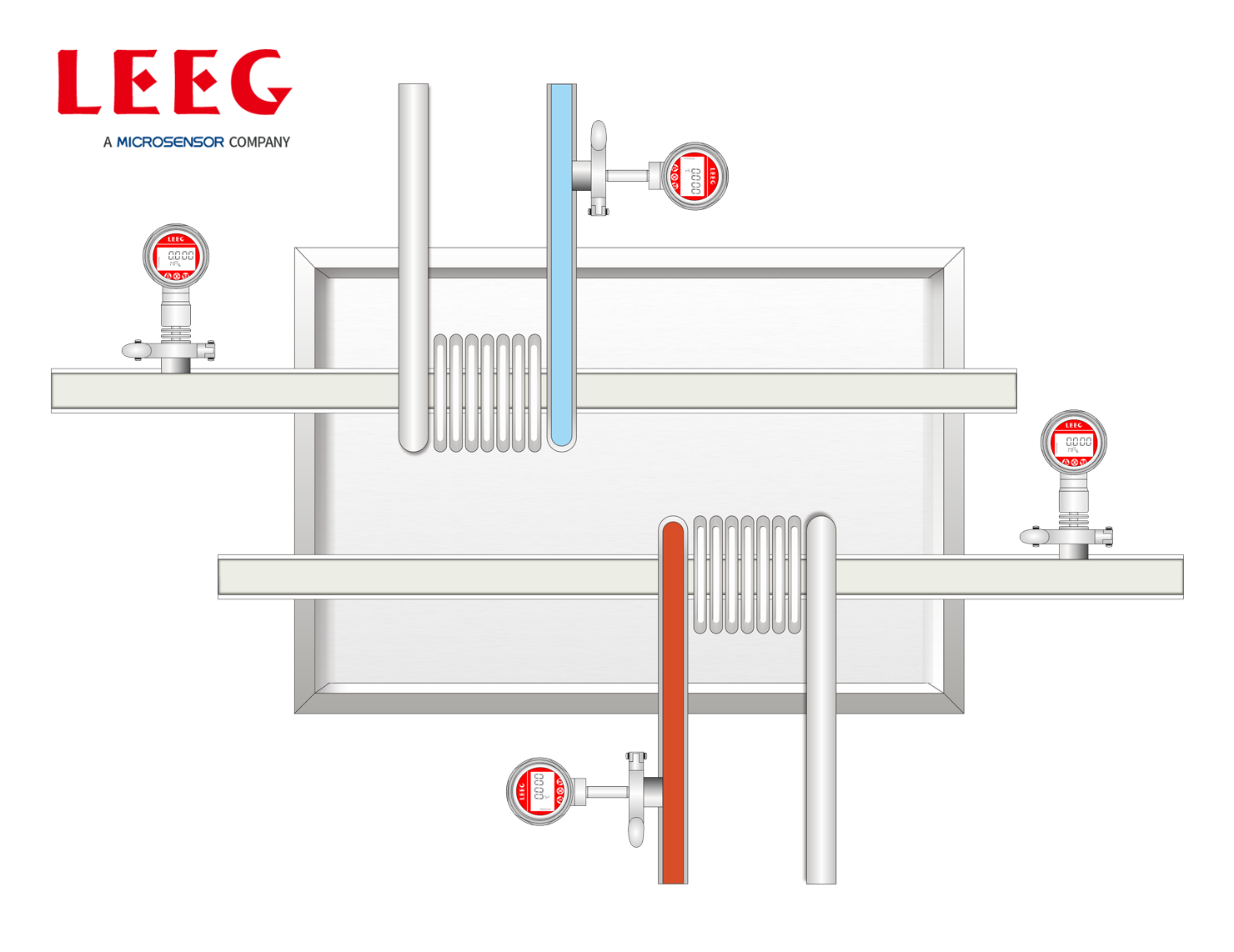

In beverage production and dairy processing, liquids are heated to specified temperatures through heat exchange, followed by rapid cooling to eradicate pathogens and prolong shelf life. Multiple stages such as heating and cooling of wort ensure that beer reaches the appropriate temperature for yeast cultivation. Both the cooler and preheater require monitoring of temperatures in the cooling and preheating tubes, as well as the pressure in the food pipelines.

more info...

The liquid preparation tank is required to prepare various solvents and basic materials for subsequent production, regardless of whether it is to prepare injections, solutions, or detergents, and it needs to proportion different types of purified water, injection water, sucrose solutions, and suspensions. By measuring the liquid level, the filling and dispensing processes are controlled, and pressure measurement is required for the inlet pipelines of different solutions to prevent tank overflow or empty running through measurement.

more info...