LCD HART Pressure Transmitter

Range:0bar~0.1bar…1000bar

HART Protocol

LCD Indicator

MPM483E

Used For

Hydrogeology, Heating and Water Supply, Mechanical Equipment Coordination, RTU Coordination

Leave a MessageMPM483E analog pressure transducer is a high-level electromagnetic compatible on-site pressure monitoring device. MPM483E is very suitable for working conditions with harsh environments. Under Micro Sensor's mature pressure transmitter design and manufacturing technology, the product has been automatically tested by computer and laser fine-tuning technology to achieve measurement accuracy. The product has undergone long-term aging tests, and its performance is stable and reliable. MPM483E high accuracy pressure transmitter is used in equipment or environments with electromagnetic interference, and occasions that require on-site pressure calibration.

Features

• Corrosion-resistant casing,

• High anti-interference ability

• With on-site display, it is convenient for inspection and observation.

Specifications

• Range: -1bar…0mbar~100mbar…1000bar

• Over pressure: ≤2×FS or 1100bar (whichever is less)

• Long-term Stability: ±0.3%FS/year

• Operation Temperature: -30℃~80℃

Image:

MPM483E analog pressure transducer is a high-level electromagnetic compatible on-site pressure monitoring device. MPM483E is very suitable for working conditions with harsh environments. Under Micro Sensor's mature pressure transmitter design and manufacturing technology, the product has been automatically tested by computer and laser fine-tuning technology to achieve measurement accuracy. The product has undergone long-term aging tests, and its performance is stable and reliable. MPM483E high accuracy pressure transmitter is used in equipment or environments with electromagnetic interference, and occasions that require on-site pressure calibration.

Features

• Corrosion-resistant casing,

• High anti-interference ability

• With on-site display, it is convenient for inspection and observation.

Specifications

• Range: -1bar…0mbar~100mbar…1000bar

• Over pressure: ≤2×FS or 1100bar (whichever is less)

• Long-term Stability: ±0.3%FS/year

• Operation Temperature: -30℃~80℃

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

LCD display Corrosion-resistant housing

High accuracy ±0.1% FS

High level EMC protection

Simultaneous hybrid output of 4-20 mA+RS485

Intrinsically safe and explosion proof certification

Pressure transmitters, level transmitters, and mass flow meters are installed in fuel tanks to provide real-time monitoring of fuel levels and pressure. Users can track current location and fuel consumption, access historical vessel data, calculate voyage distance and total fuel usage, and analyze operational efficiency.

more info...

The papermaking process generates large amounts of pulp and chemicals, requiring the use of towers, pools, tanks, and other containers for storage and transportation. Installing intelligent pressure transmitters that can work in conjunction with computer control systems allows for timely monitoring of pressure, differential pressure, and flow information, effectively improving production efficiency and reducing losses.

more info...

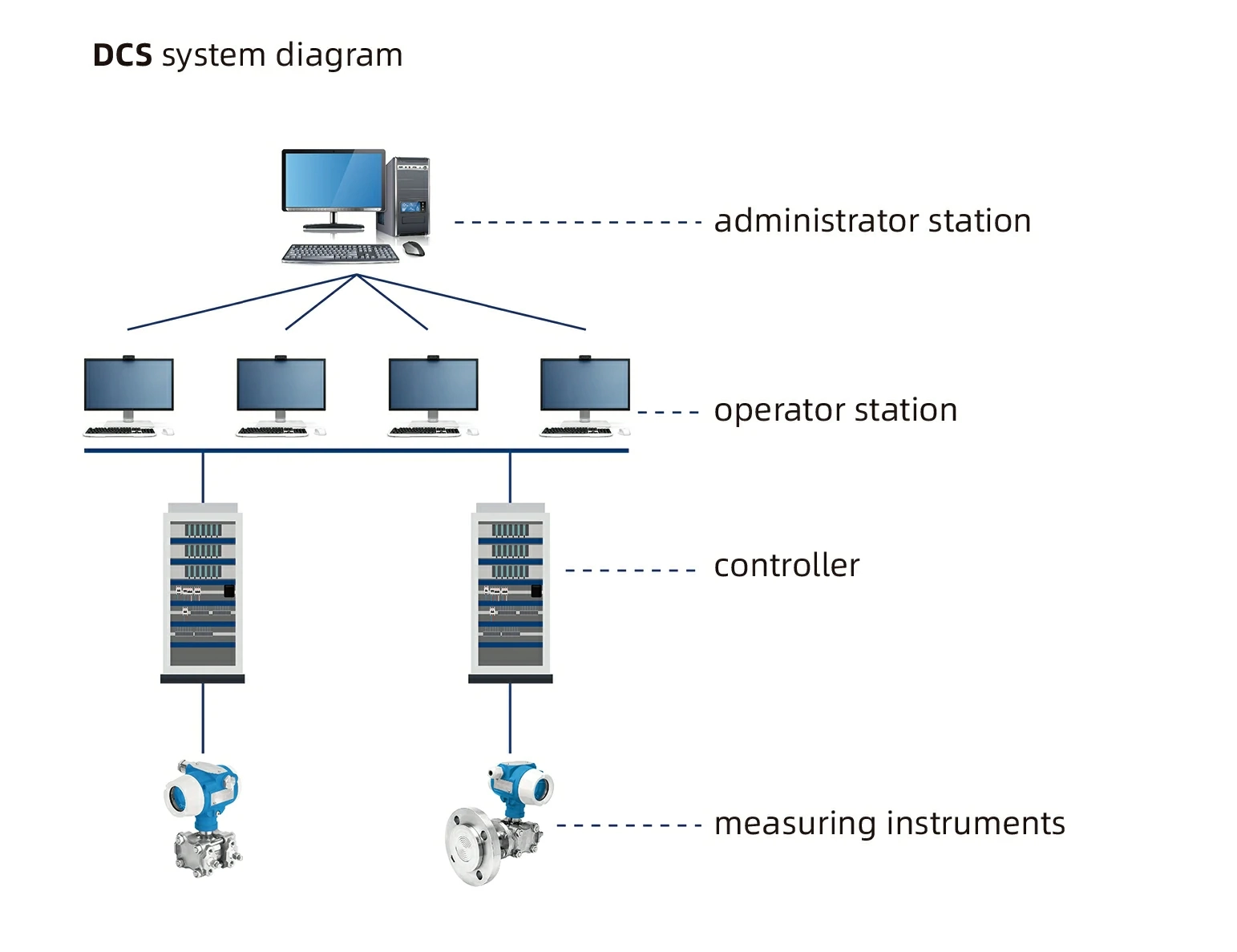

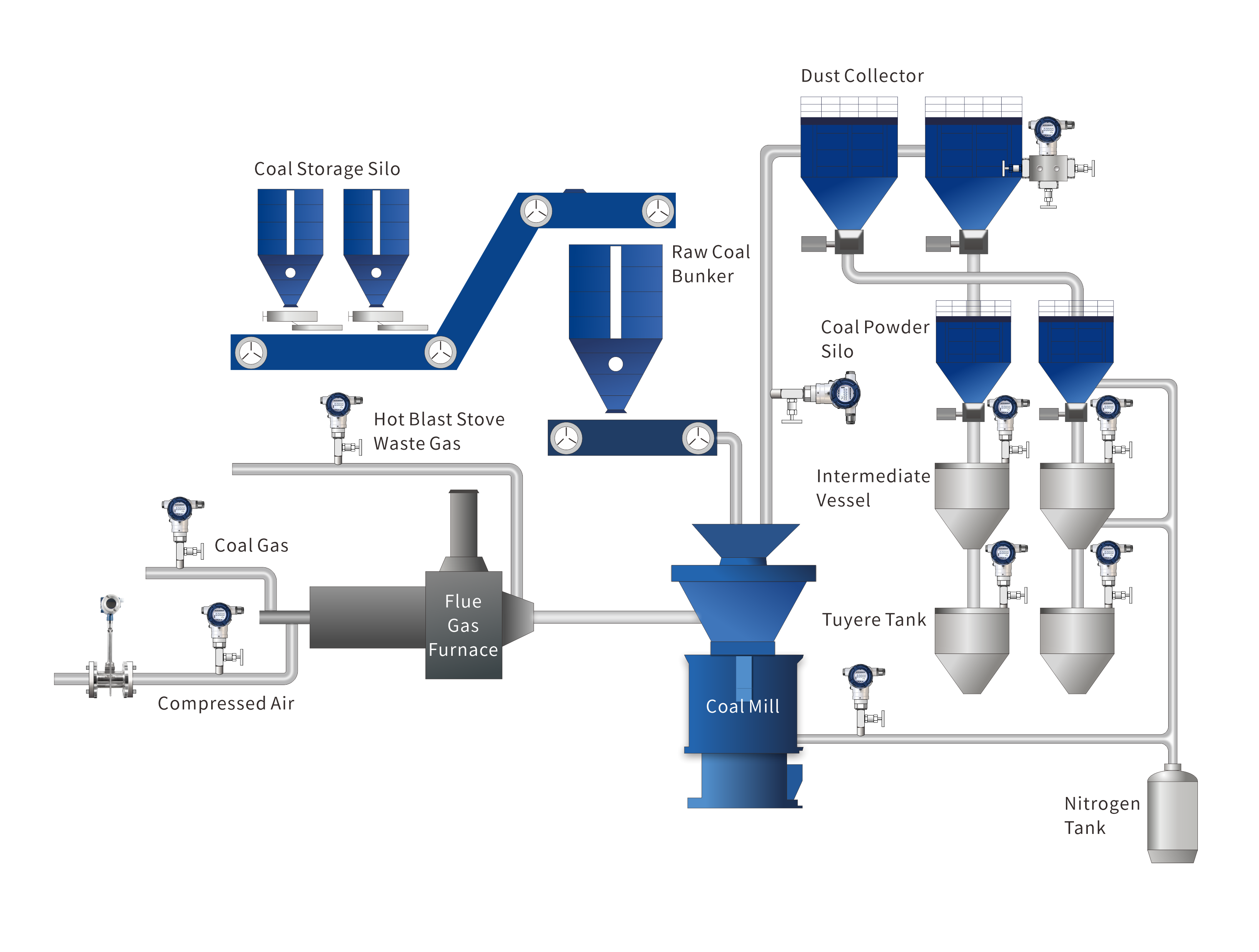

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the metallurgy industry to ensure smelting process efficiency and product quality. In the demanding high-temperature, high-pressure, and harsh environments of the metallurgy industry, Micro Sensor comprehensive monitoring solutions provide real-time data acquisition and precise regulation by integrating smart control systems and advanced sensor technologies. These systems optimize metal production processes for safe and effective operations.

more info...

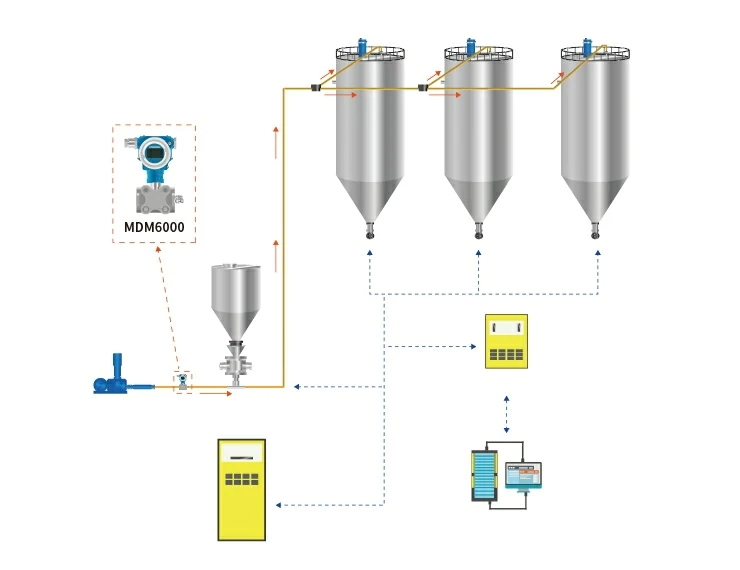

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...