ATEX Pressure Transmitter

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

MPM486

Used For

Industrial Automation, Oil and Gas Industry, Chemical and Pharmaceutical Industry, Wastewater and Water Treatment, Food and Beverage Industry

Leave a MessageThe MPM486 LCD HART Pressure Transmitter is suitable for precise measurement of fluid pressure. MPM486 digital display pressure transmitter adopts advanced manufacturing technology, and adopts temperature compensation and linear correction in the production process. This product is an intelligent pressure measurement product that complies with the HART protocol. Users can use the HART communicator to monitor and manage HART instruments running in the process. The LCD display supports the on-site configuration of buttons.

Features

4~20mA output + HART® (2-wire)

High accuracy & Wide measuring range

-10~80℃ digital temperature compensation

Reliable explosion-proof construction

Specification

• Range: 0bar~0.1bar...1000bar

• Stability: ≤±0.25 %FS/year

• Operation temp.: -30~80 ℃

• Protection: IP65

Image:

The MPM486 LCD HART Pressure Transmitter is suitable for precise measurement of fluid pressure. MPM486 digital display pressure transmitter adopts advanced manufacturing technology, and adopts temperature compensation and linear correction in the production process. This product is an intelligent pressure measurement product that complies with the HART protocol. Users can use the HART communicator to monitor and manage HART instruments running in the process. The LCD display supports the on-site configuration of buttons.

Features

4~20mA output + HART® (2-wire)

High accuracy & Wide measuring range

-10~80℃ digital temperature compensation

Reliable explosion-proof construction

Specification

• Range: 0bar~0.1bar...1000bar

• Stability: ≤±0.25 %FS/year

• Operation temp.: -30~80 ℃

• Protection: IP65

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Heavy Duty & Shock Resistance

16Bar~1000Bar

Accuracy:±1%FS

High-level electromagnetic compatibility

Support reverse polarity, transient overcurrent and over-voltage protection

LCD / LED display

CE approved

LCD display Corrosion-resistant housing

High accuracy ±0.1% FS

High level EMC protection

Simultaneous hybrid output of 4-20 mA+RS485

Intrinsically safe and explosion proof certification

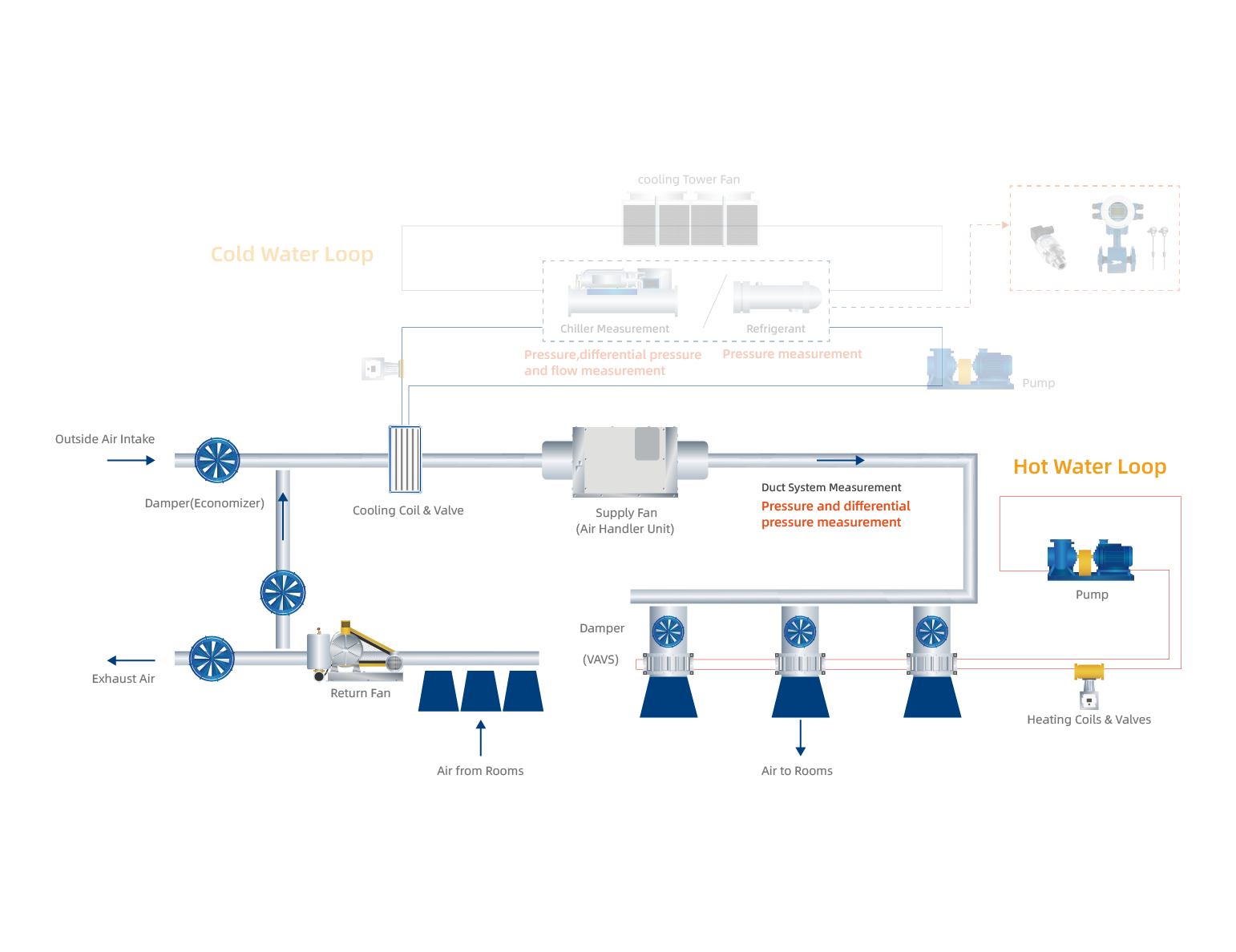

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...

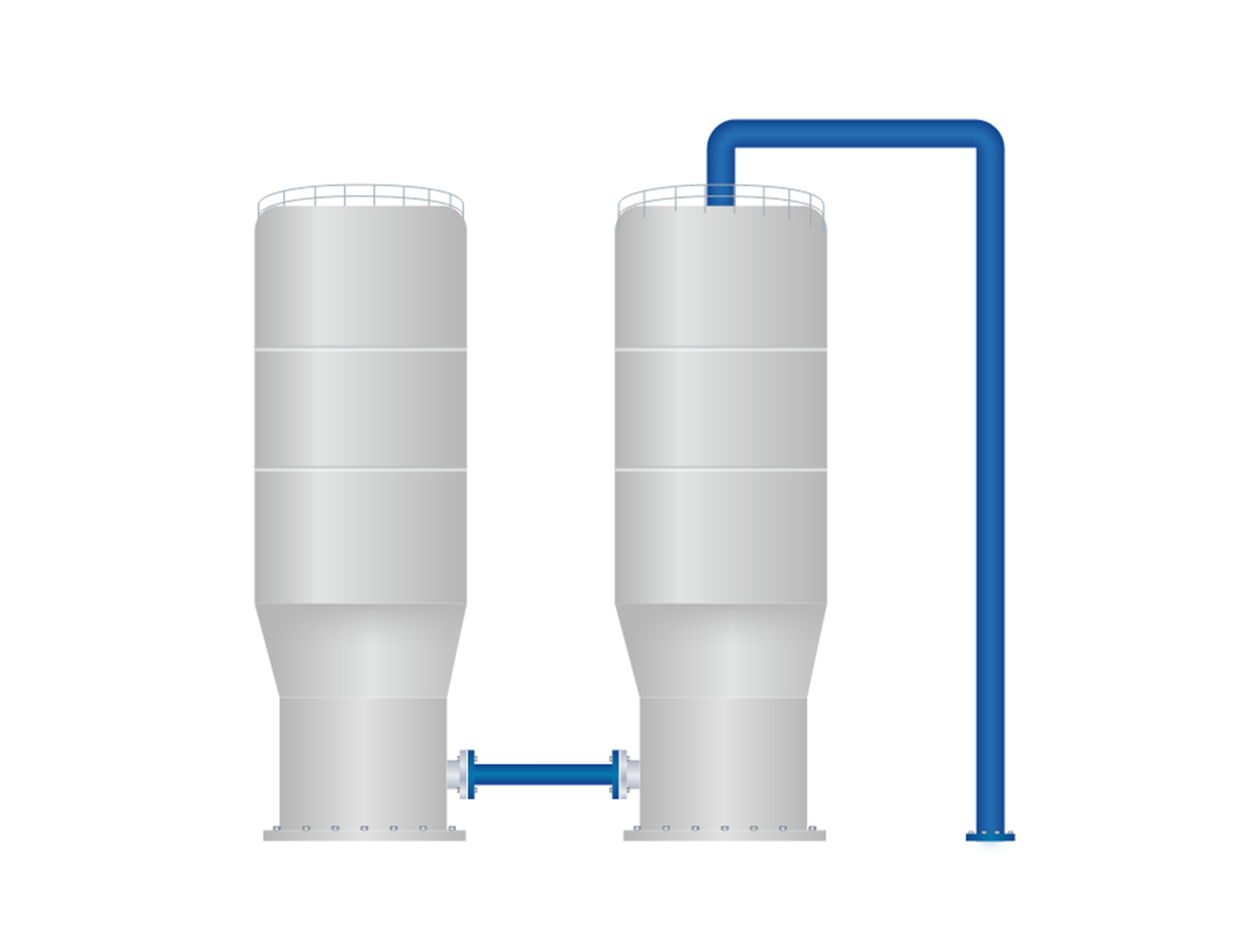

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

High-speed paper mills use a vacuum system with turbine blowers to facilitate dewatering. The vacuum level, which is controlled by motor speed, must be continuously monitored. In addition, to ensure safe vacuum pump/blower operation, the lubrication status of bearings is maintained by measuring lubricant pressure and reservoir level.

more info...

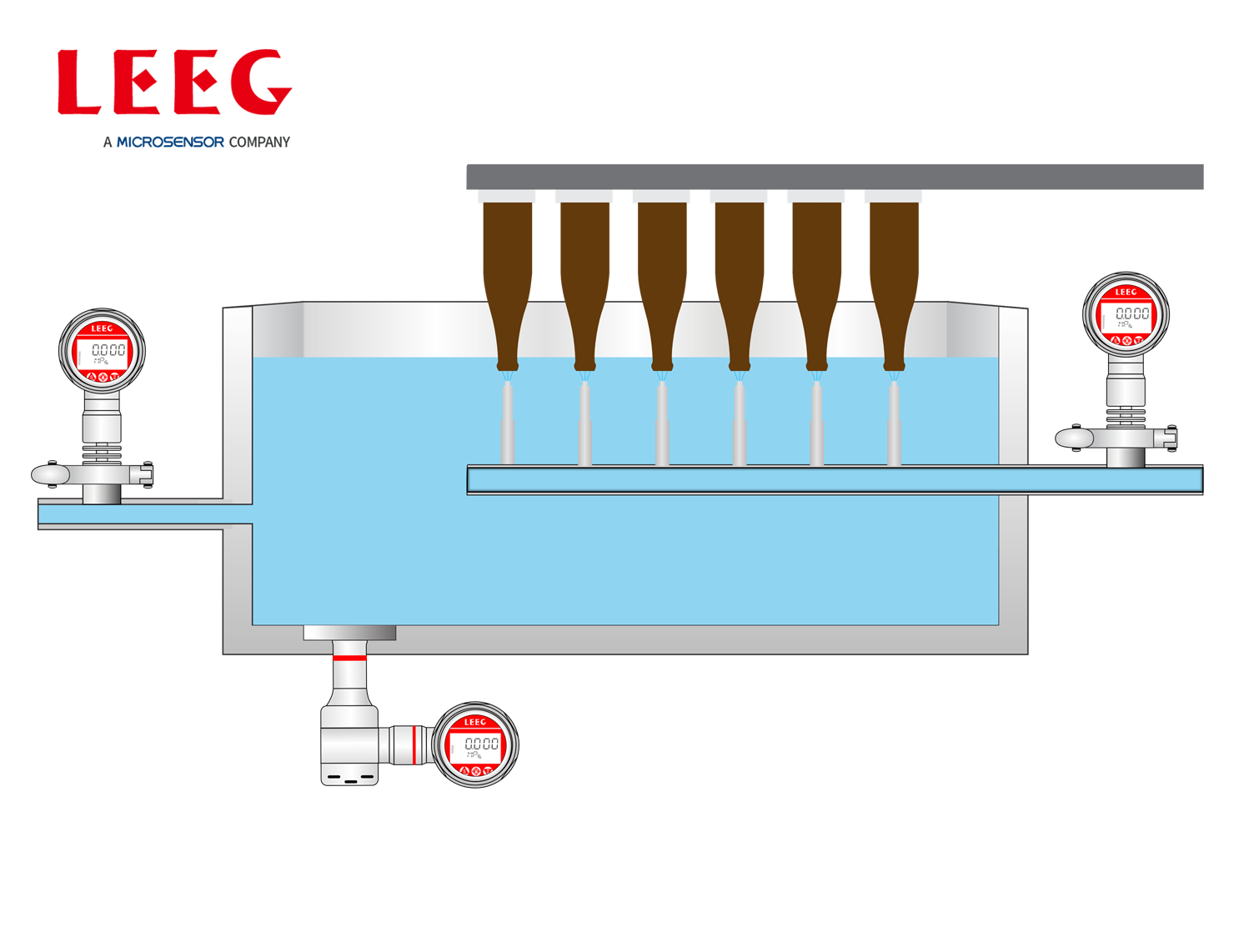

Before beer bottles, medicine bottles, and condiment bottles are filled with liquid, they need to be cleaned first. The cleaning process is as follows: First, the bottles are filled with lye in the alkali tank to remove most of the stains; then, the bottles are back washed with high pressure using water of different temperatures to wash away the remaining impurities and lye. To ensure the stable operation of the bottle washing machine, the level of the alkali tank needs to be measured by hydrostatic pressure. In addition, the pressure of the alkali tank water inlet pipe and the nozzle pipe also needs to be measured.

more info...