ATEX Pressure Transmitter

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM483DM

Used For

Oil & Gas Extraction, Petroleum and Petrochemical Engineering, Power Industry, Mechanical Engineering, Hydraulic and Pneumatic Control

Leave a MessageThe MPM483DM explosion-proof digital pressure transmitter showcases advanced features in various pressure measurement applications. MPM483DM boasts an explosion-proof design, ensuring safe operation in hazardous environments. The transmitter meets stringent industry standards and certifications for explosion-proof devices. The robust construction can endure extreme temperatures, vibrations, and other challenges typically encountered in industrial environments.

Feature

• High-precision, high-stability

• High level of electromagnetic compatibility

• Widely for explosion-proof Industries

• Integration with control systems

Image:

The MPM483DM explosion-proof digital pressure transmitter showcases advanced features in various pressure measurement applications. MPM483DM boasts an explosion-proof design, ensuring safe operation in hazardous environments. The transmitter meets stringent industry standards and certifications for explosion-proof devices. The robust construction can endure extreme temperatures, vibrations, and other challenges typically encountered in industrial environments.

Feature

• High-precision, high-stability

• High level of electromagnetic compatibility

• Widely for explosion-proof Industries

• Integration with control systems

-1bar...0mbar~100mbar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.1%FS

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

High-level electromagnetic compatibility

Support reverse polarity, transient overcurrent and over-voltage protection

LCD / LED display

CE approved

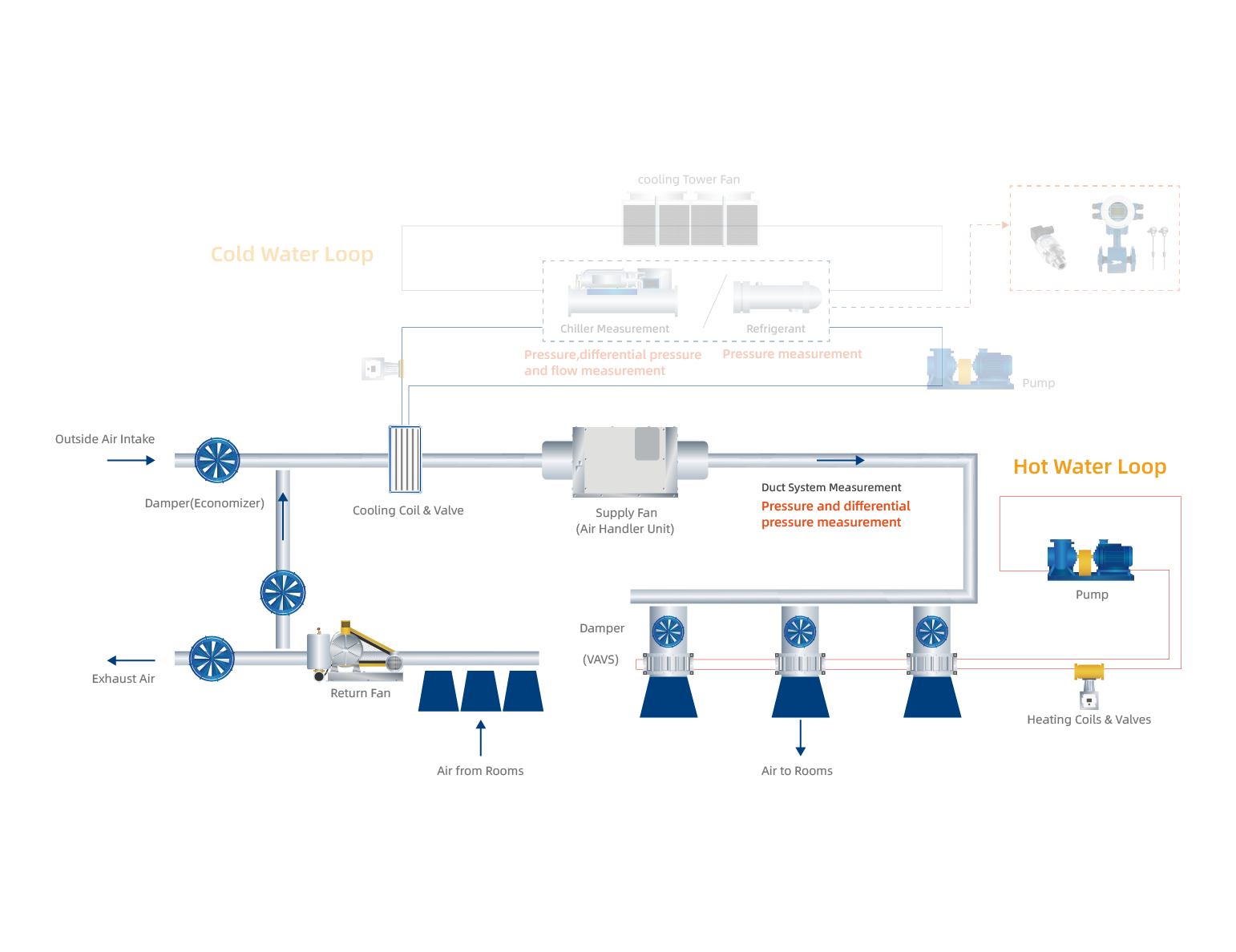

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...

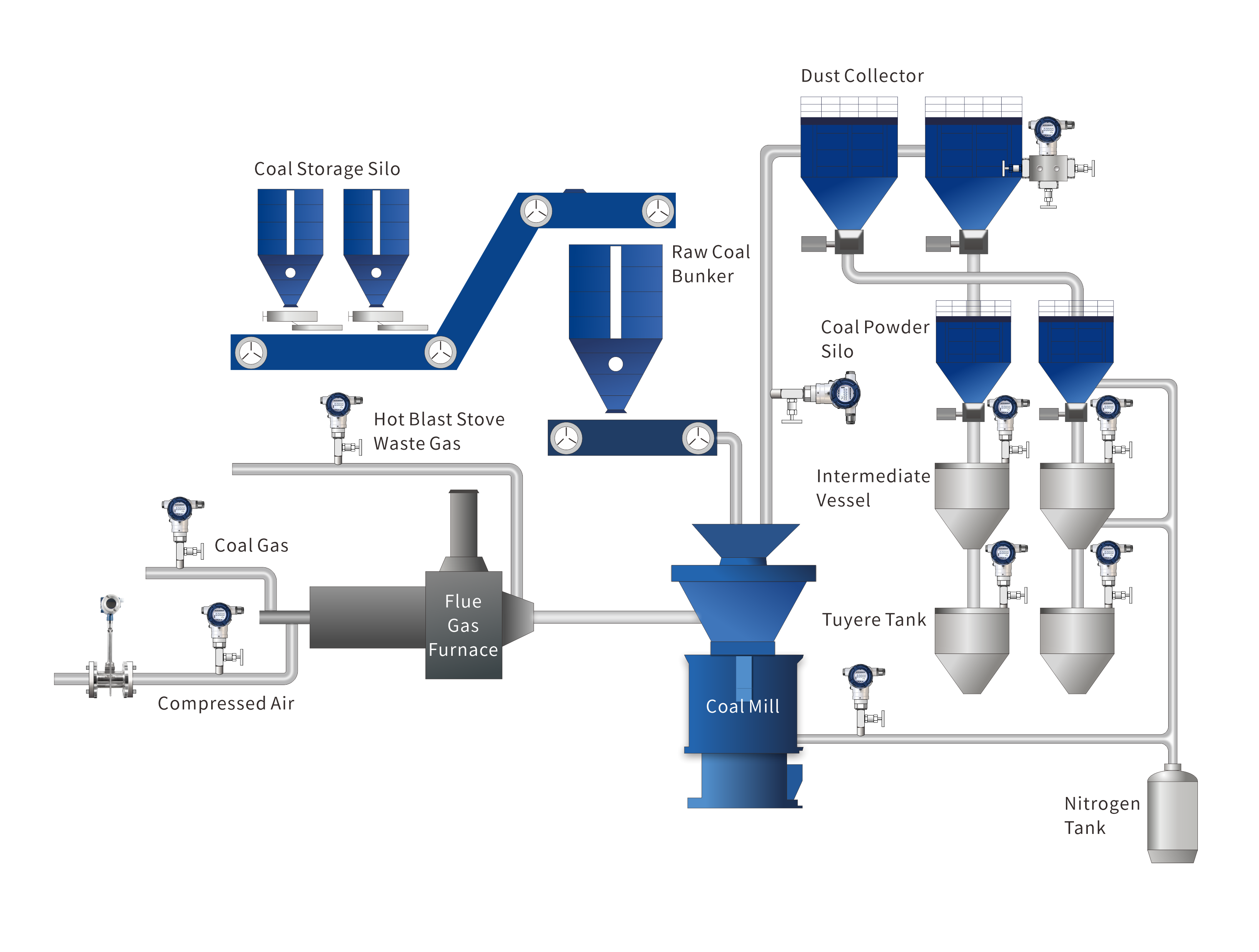

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the metallurgy industry to ensure smelting process efficiency and product quality. In the demanding high-temperature, high-pressure, and harsh environments of the metallurgy industry, Micro Sensor comprehensive monitoring solutions provide real-time data acquisition and precise regulation by integrating smart control systems and advanced sensor technologies. These systems optimize metal production processes for safe and effective operations.

more info...

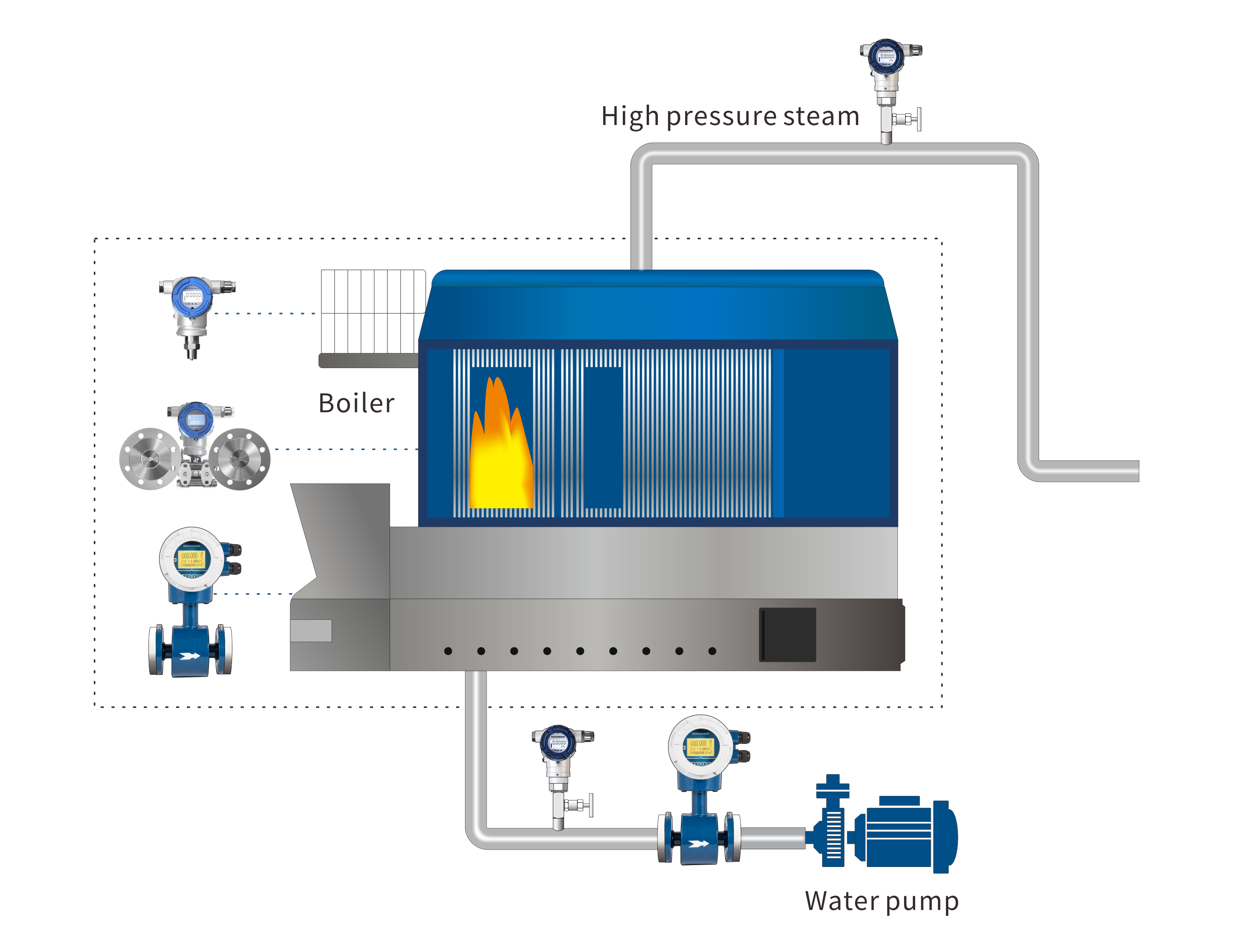

In the electric power industry, especially in power plants and transmission systems, it is very important to accurately monitor and control pressure, level, temperature and flow, because these specifications will directly affect the operating efficiency and safety of the system. Micro Sensor's monitoring instrumentation solutions integrate advanced sensor technology and intelligent control systems, which can provide accurate data and efficient control even in complex environments, and optimize the power production and transmission process.

more info...

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

more info...