Application Introduction

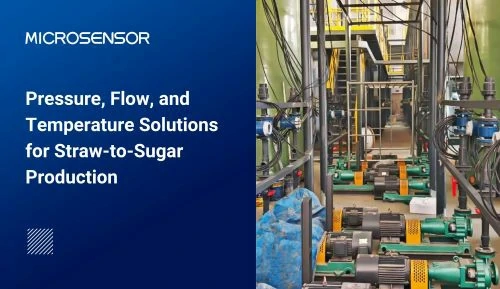

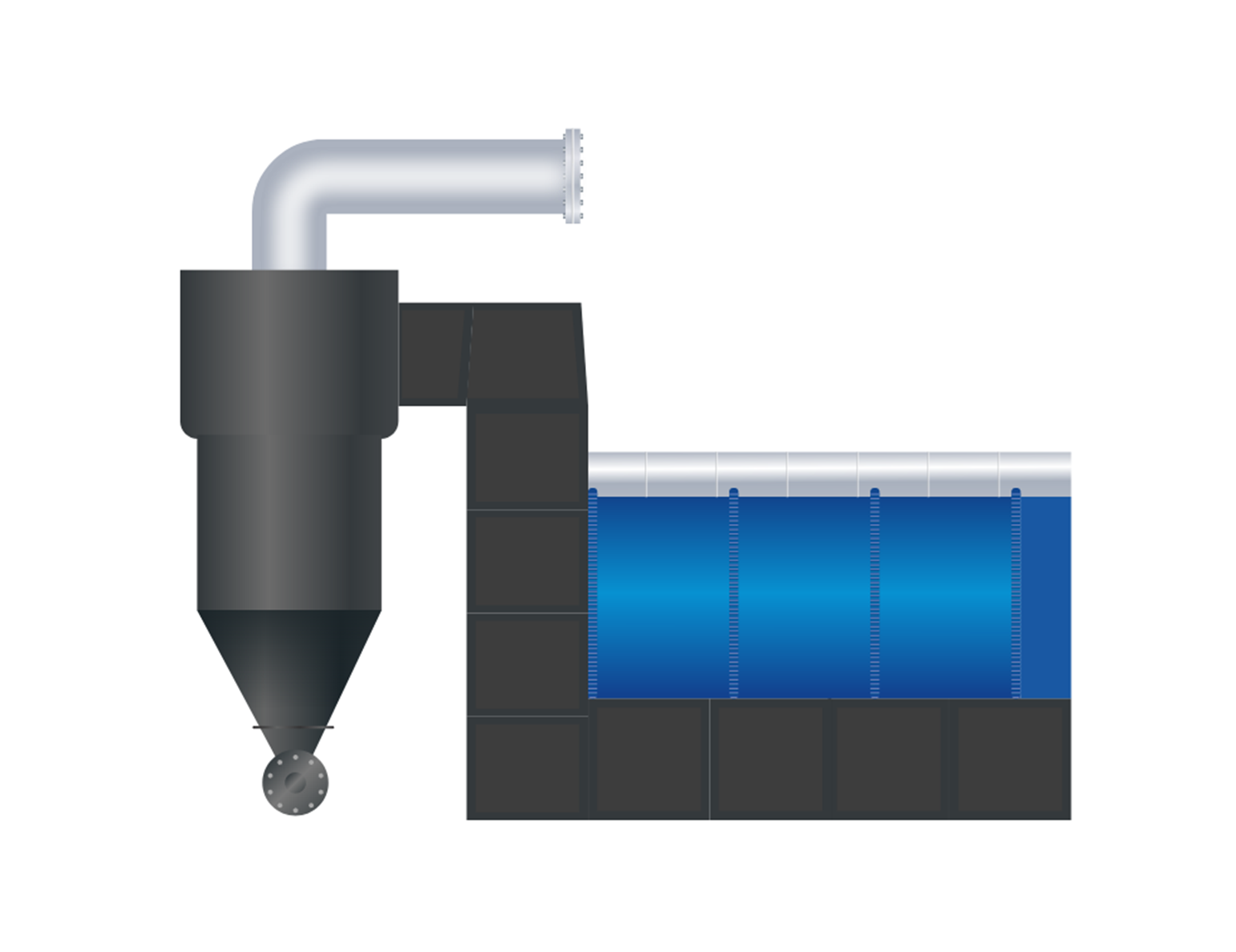

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

Contact Engineer

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD