Application Introduction

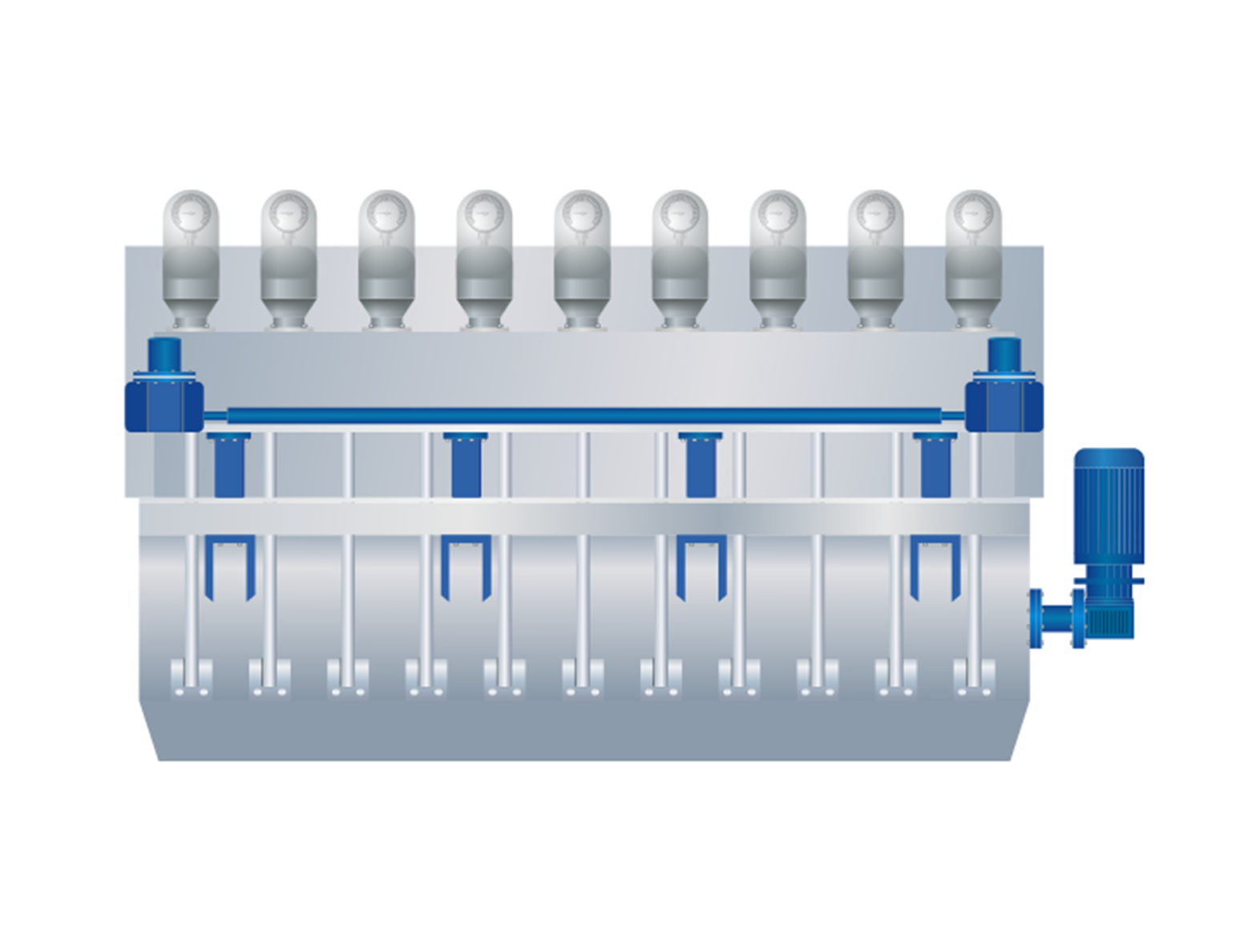

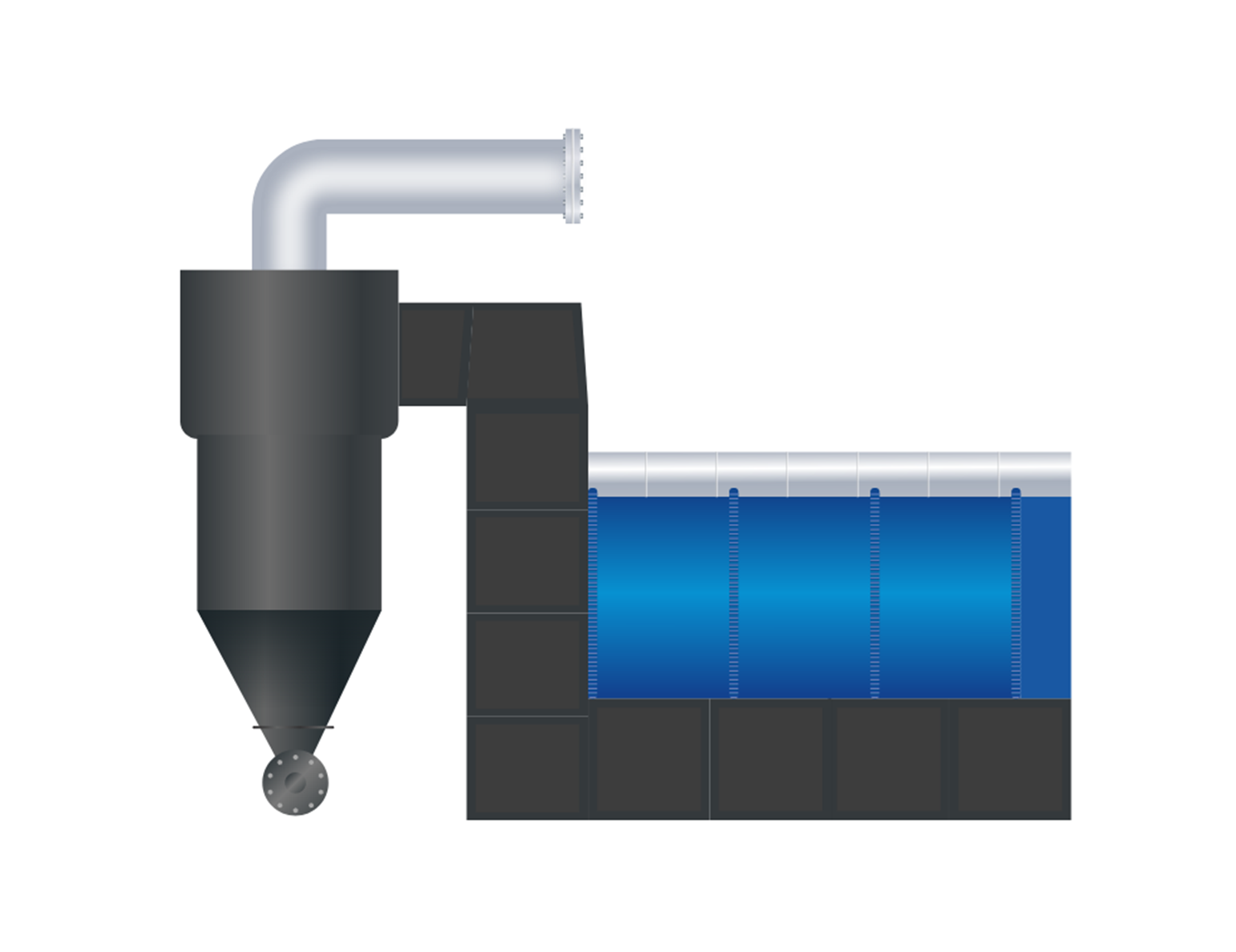

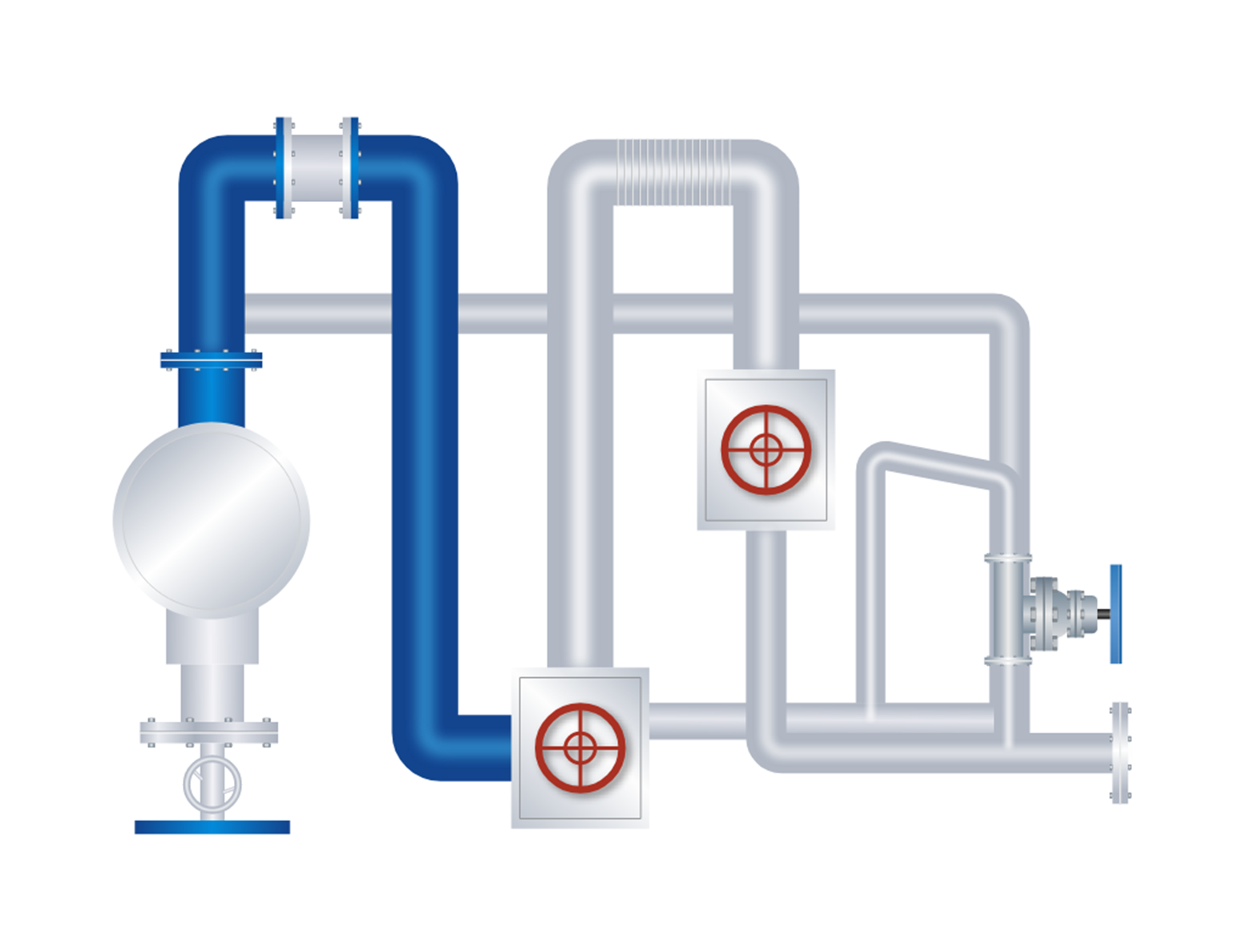

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

Contact Engineer

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD