Hygienic Temperature Transmitter

Measuring range: -50~400℃

Output signal: 4~20mA、Modbus-RTU/RS485 and others

Reference accuracy: ±0.5% upper range limit

MTM4831

Used For

Petroleum, Chemical Industry, Metallurgy, Power Station, Light Industry and Others

Leave a MessageMTM4831 Temperature Transmitter is uesd for the temperature measurement of different applications in the industries of petroleum chemical industry, metallurgy and others. It is used to measure the temperature of various liquids, gaseous media and solid surfaces between -200°C and 500°C. There are standard analog and digital signal output signal. The temperature transmitter is zero and span adjustable. The product is easy to install and meets different output signal requirements.

The MTM4831 provides temperature measuring for pipelines, storage tanks, reactors, and other process equipment in harsh environments. It offers the accuracy and reliability of an industrial temperature measurement system component.

Feature

• Use a particular temperature module

• Easy to use, various output

• Meet the temperature measurement of different sites

Specifications

• Temperature Ranges: -200℃…0℃~500℃

• Power Supply: 10V ~ 30V DC

• Output: 4~20mA DC, 4~20mA DC + HART, 4~20mA DC + RS485, RS485, Thermal Resistance

• Accuracy: ±1.0%FS, ±0.5%FS, ±0.25%FS

• Display: 4-digit LCD/LED

• Stability: ±0.5%FS/year (general)

Image:

MTM4831 Temperature Transmitter is uesd for the temperature measurement of different applications in the industries of petroleum chemical industry, metallurgy and others. It is used to measure the temperature of various liquids, gaseous media and solid surfaces between -200°C and 500°C. There are standard analog and digital signal output signal. The temperature transmitter is zero and span adjustable. The product is easy to install and meets different output signal requirements.

The MTM4831 provides temperature measuring for pipelines, storage tanks, reactors, and other process equipment in harsh environments. It offers the accuracy and reliability of an industrial temperature measurement system component.

Feature

• Use a particular temperature module

• Easy to use, various output

• Meet the temperature measurement of different sites

Specifications

• Temperature Ranges: -200℃…0℃~500℃

• Power Supply: 10V ~ 30V DC

• Output: 4~20mA DC, 4~20mA DC + HART, 4~20mA DC + RS485, RS485, Thermal Resistance

• Accuracy: ±1.0%FS, ±0.5%FS, ±0.25%FS

• Display: 4-digit LCD/LED

• Stability: ±0.5%FS/year (general)

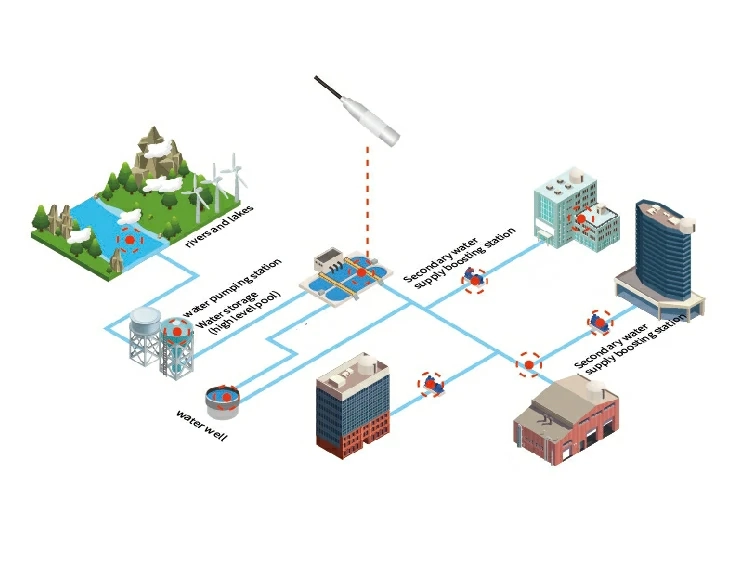

Monitoring the pressure, flow and other specifications of the entire pipe network by installing the monitoring device in water supply pipe network well contributes to scientifically scheduling water supply and ensuring the stable operation of the water supply system.

more info...

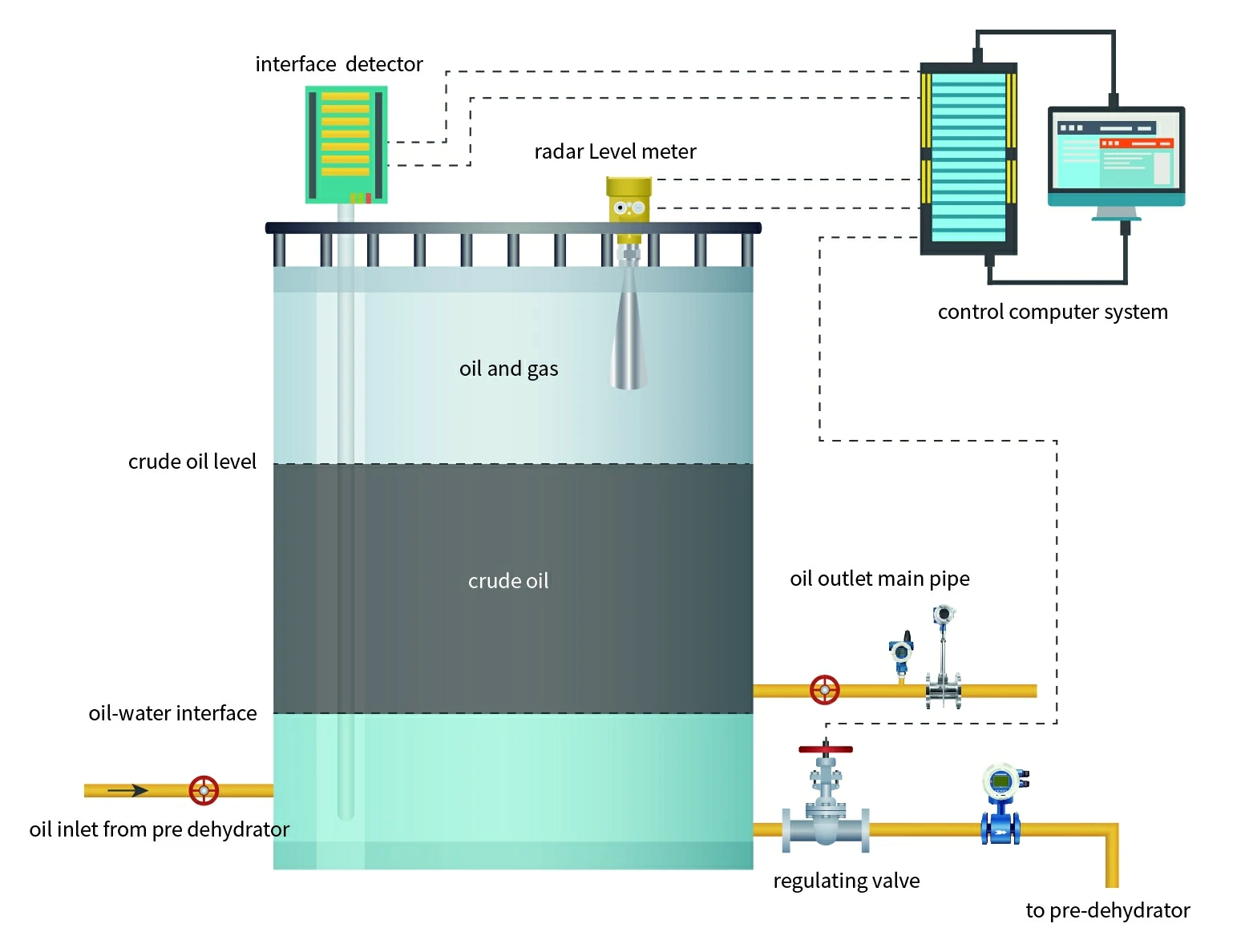

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...

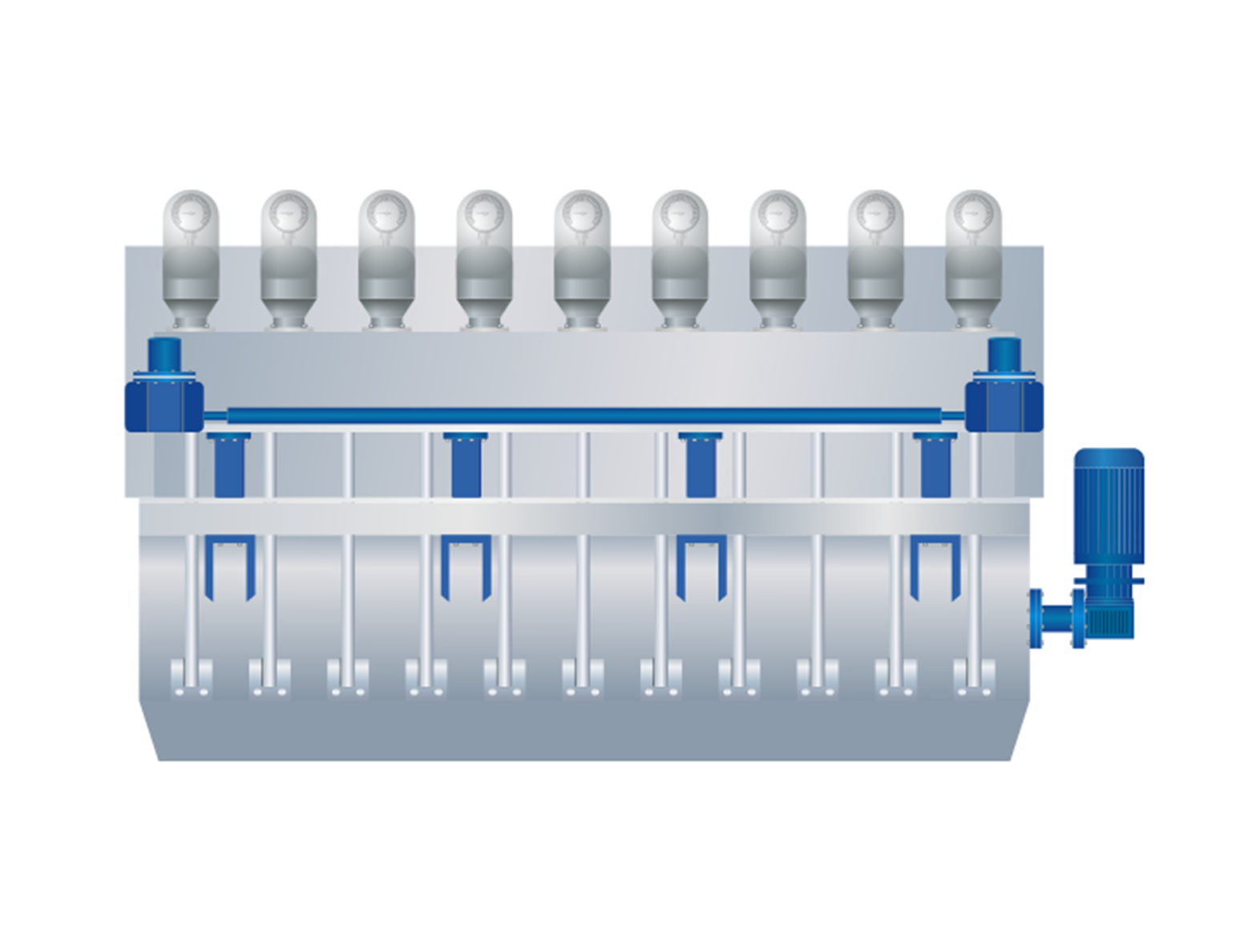

In the papermaking process, pulp is fed into the headbox of the paper machine. In the hydraulic headbox, pulp enters the weir pool via the conical distribution pipe and tube bundles, and is then sprayed onto the forming wire by the weir plate. Since the pulp jet velocity is controlled by adjusting the headbox slice pressure per the wire speed, accurate pressure measurement in the headbox is essential.

more info...

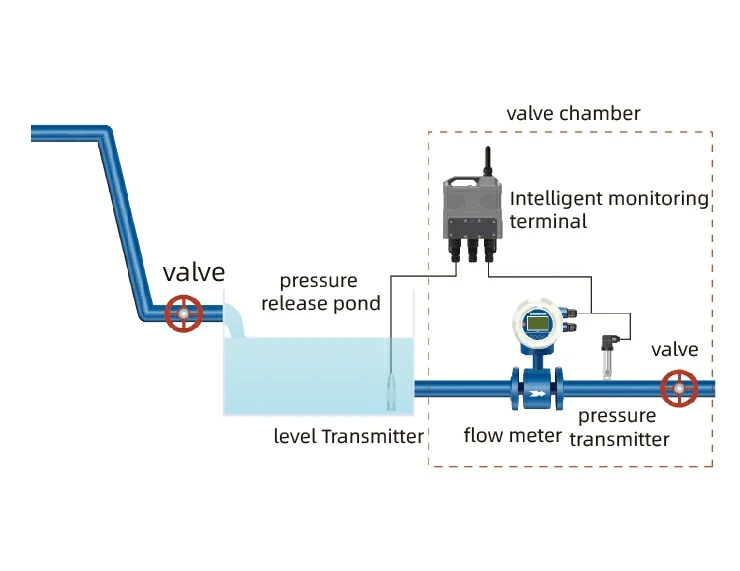

The pressure-release pond can regulate the pressure of the water supply network. It adjusts the pipe network pressure by increasing or decreasing the water volume. The pond maintains the pipelines at a normal level. At various stages of the pressure-release pond, different instruments need to be installed.

more info...