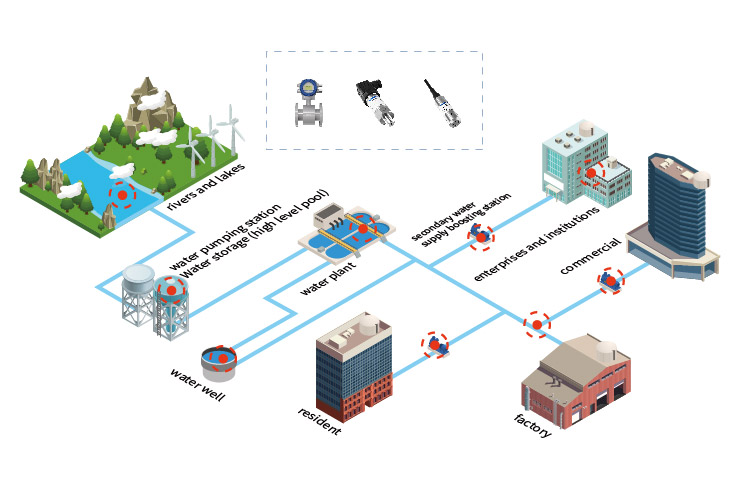

Utility water systems encompass the entire water delivery process, from source to tap, and pressure monitoring is critical at every process. The locations where water pressure sensors are placed are determined by the specific goals of the monitoring. Here are the most common and vital locations. The following will introduce where and how water pressure sensors work in the three main processes of utility water systems: source, treatment, and storage & distribution.

Where and How Does Water Pressure Sensor Work?

Water Source

• Location 1: Wells

The most common way to extract groundwater is to drill wells, which are then pumped to the surface. The submersible pressure transducer is installed at the bottom of the well, to continuously monitor the water levels. It typically works with a pump to help manage pumping rates, prevent over-pumping, and protect the well's operation.

• Location 2: Surface Water Intakes

Pressure measurement at the intake ensures adequate surface water flow into the reservoir or treatment plant. The water pressure transmitter simultaneously detects blockages or low water levels.

• Location 3: Reservoir Outlet

The main purpose of measurement and monitoring is water resource management. The instruments help understand how much water is available. It also provides critical pressure and level data for flood control and power optimization.

Water Treatment

Water pressure transducers monitor and control various stages of the treatment process. Here's where and how they work:

• Location 1: Pump Stations

Monitoring the discharge pressure of pumps to ensure they are operating within their design parameters and to control pump speed.

• Location 2: Filtration Systems

A significant pressure reduction indicates that the filter is becoming clogged. It's time for cleaning or replacement. Pressure transmitters can also trigger alarms when pressures exceed or drop below set thresholds.

• Location 3: Storage Tanks

The water level measures the hydrostatic pressure at the bottom of the tank. Accurate level measurement ensures that storage tanks are neither overfilled nor too empty, which can affect the efficiency of the treatment process.

Storage & Distribution

• Location 1: Pump Stations

Measures the pressure as water leaves the pump. This is critical for monitoring pump performance, ensuring the pump is operating within its design parameters, and detecting issues like pump cavitation or impeller wear.

Measures the pressure on the intake side of the pump. Low suction pressure can indicate problems with the water source or blockages in the intake pipe, potentially leading to pump damage.

• Location 2: Booster Stations

The booster pump lifts the water pressure from the lower level to the ideal value. The pressure transmitters in the boost pump system measure the pressure of the fluid within the pipeline. Controlling pressure to maintain consistent water supply in elevated areas or areas far from the plant.

• Location 3: Water Supply Network/Pipes

The water supply pipe network should have water pressure sensors installed at intervals.

Areas Near Large Water Users (e.g., Industrial Facilities, Hospitals): These users can create significant pressure fluctuations. Monitoring nearby helps understand the impact of their usage and ensures adequate pressure for other customers.

District Metering Areas (DMAs): At the inlet and outlet of each DMA. This is essential for leak detection and pressure management within the isolated zone.

General Principles for Placement of Water Pressure Sensors

• Accessibility: Ensure that the water pressure sensors are easily accessible for maintenance, calibration, and replacement.

• Representativity: Choose locations that provide a representative or valuable measurement for the specific monitoring objectives (e.g., leak detection, pressure optimization, hydraulic model calibration).

• Stability: The water pressure sensor should be mounted in a stable location to minimize errors due to movement or vibration.

• Security: Protect sensors from extreme weather, sabotage, or unauthorized access.

Summary

Water pressure sensors are strategically placed throughout the utility water supply system – from the source to the end-user – to monitor system performance, detect problems, and ensure reliable water delivery. The specific locations depend on the size and complexity of the system and the goals of the monitoring program.

Is there a particular measurement solution for the water supply system you're interested in? MicroSensor's experts are willing to help you choose a suitable water pressure sensor or offer a more specific recommendation.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD