17mm Submersible Level Transmitter

φ17mm

0m~10m…200mH2O

Measurement Accuracy: ±0.5%FS

MPM489W

Used For

Water Level Measurement of Sewage, Sea Water, Underground Water and Chemical Plant Wasted Water

Leave a MessageMPM489W submersible water level transmitter is ATEX explosion-proof and RoHS certificated that support measuring gasoline, diesel and other media. MPM489W is IP68 protected with an integrated structure. The level transmitter outputs analog 4mA~20mADC, 0~5/10VDC and 0.5V~4.5V DC. The measurement ranges from 1m to 200m.

MPM489W is an ideal measurement instrument for field service and automation control. It measures and monitors the level of liquids or solids in tanks or containers. It can also be used for medicine, city water supply and drainage and hydrology, etc.

Feature

• General Industries

• Integrated Structure, Standard Outputs

• CE, RoHS, ATEX, CCS, and DNV approved

Image:

MPM489W submersible water level transmitter is ATEX explosion-proof and RoHS certificated that support measuring gasoline, diesel and other media. MPM489W is IP68 protected with an integrated structure. The level transmitter outputs analog 4mA~20mADC, 0~5/10VDC and 0.5V~4.5V DC. The measurement ranges from 1m to 200m.

MPM489W is an ideal measurement instrument for field service and automation control. It measures and monitors the level of liquids or solids in tanks or containers. It can also be used for medicine, city water supply and drainage and hydrology, etc.

Feature

• General Industries

• Integrated Structure, Standard Outputs

• CE, RoHS, ATEX, CCS, and DNV approved

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

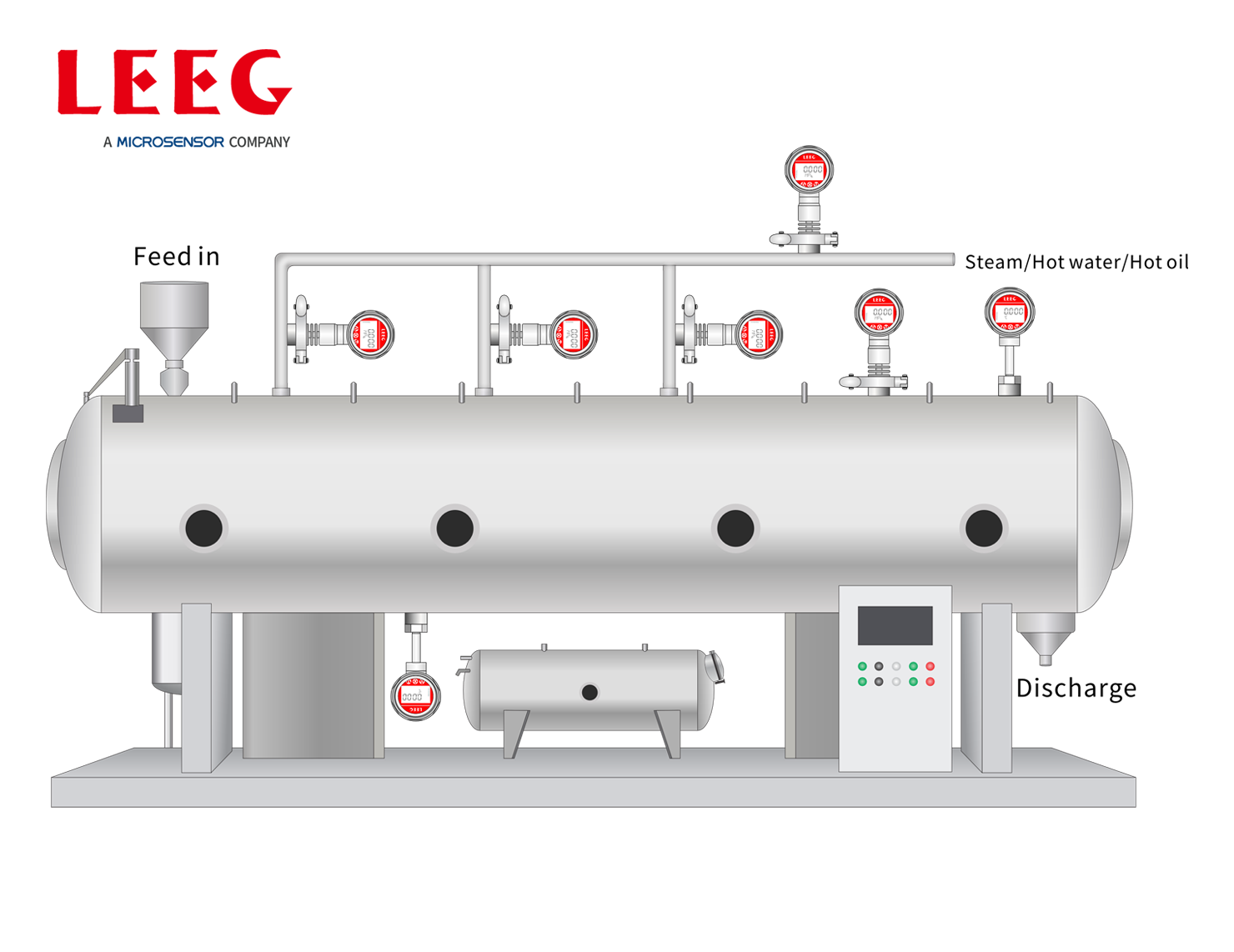

Dryers are often used to dry medicines or extract active ingredients from traditional Chinese medicines, which are easily decomposed in high temperature environments. Temperature measurement is required in the heating area, cooling area and material outlet of the dryer, and pressure transmitters are used to measure the pressure of air or gas to help adjust the air flow speed and fan operation status, or measure the pressure of steam, hot water, and hot oil pipelines.

more info...

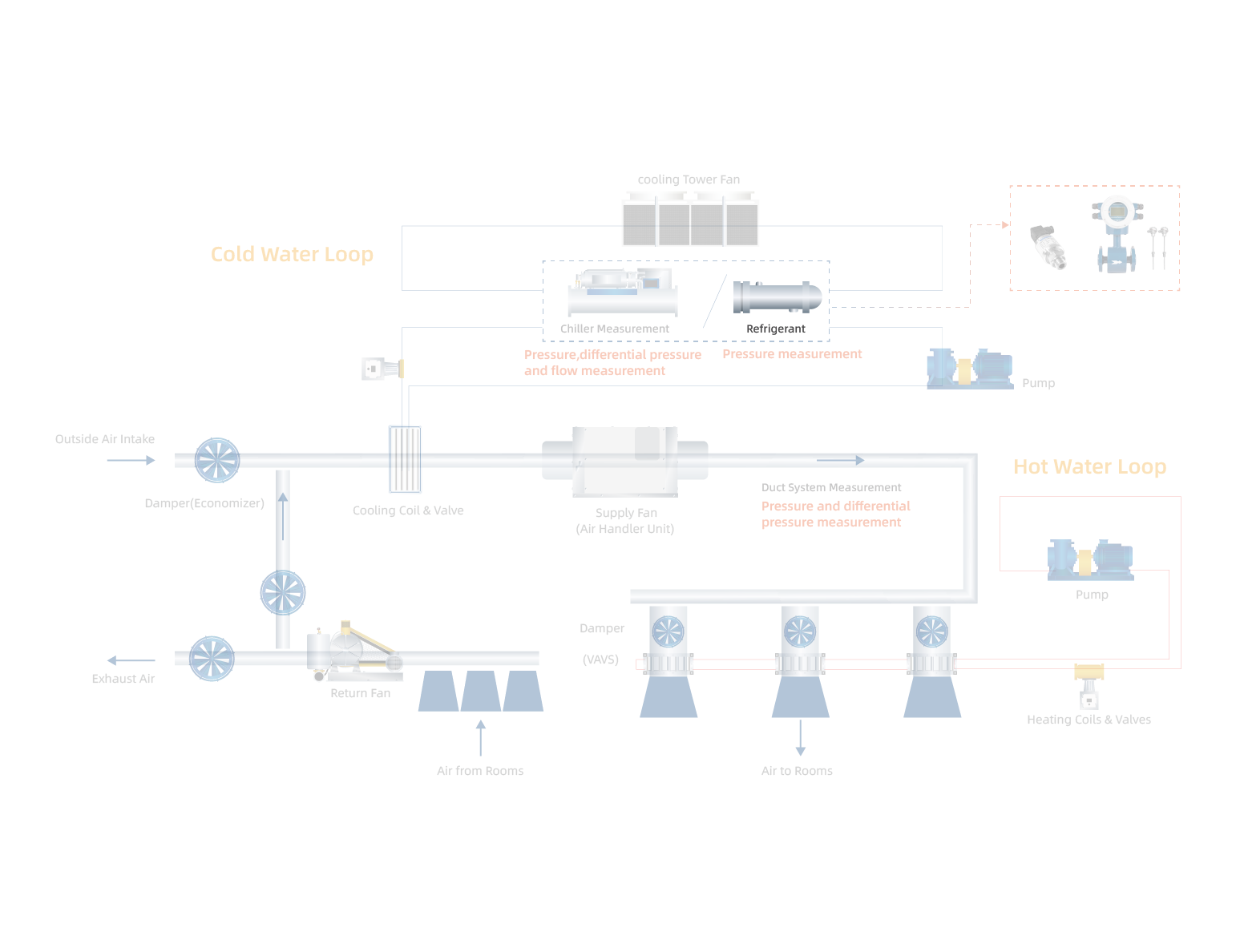

In HVAC systems, measuring the pressure of refrigerants is critical. Pressure transmitters monitor the refrigerant's pressure to ensure it operates within safe limits, preventing leaks and system failures. Accurate pressure measurement enhances system efficiency, ensures optimal cooling performance, and maintains safety by detecting potential issues early

more info...

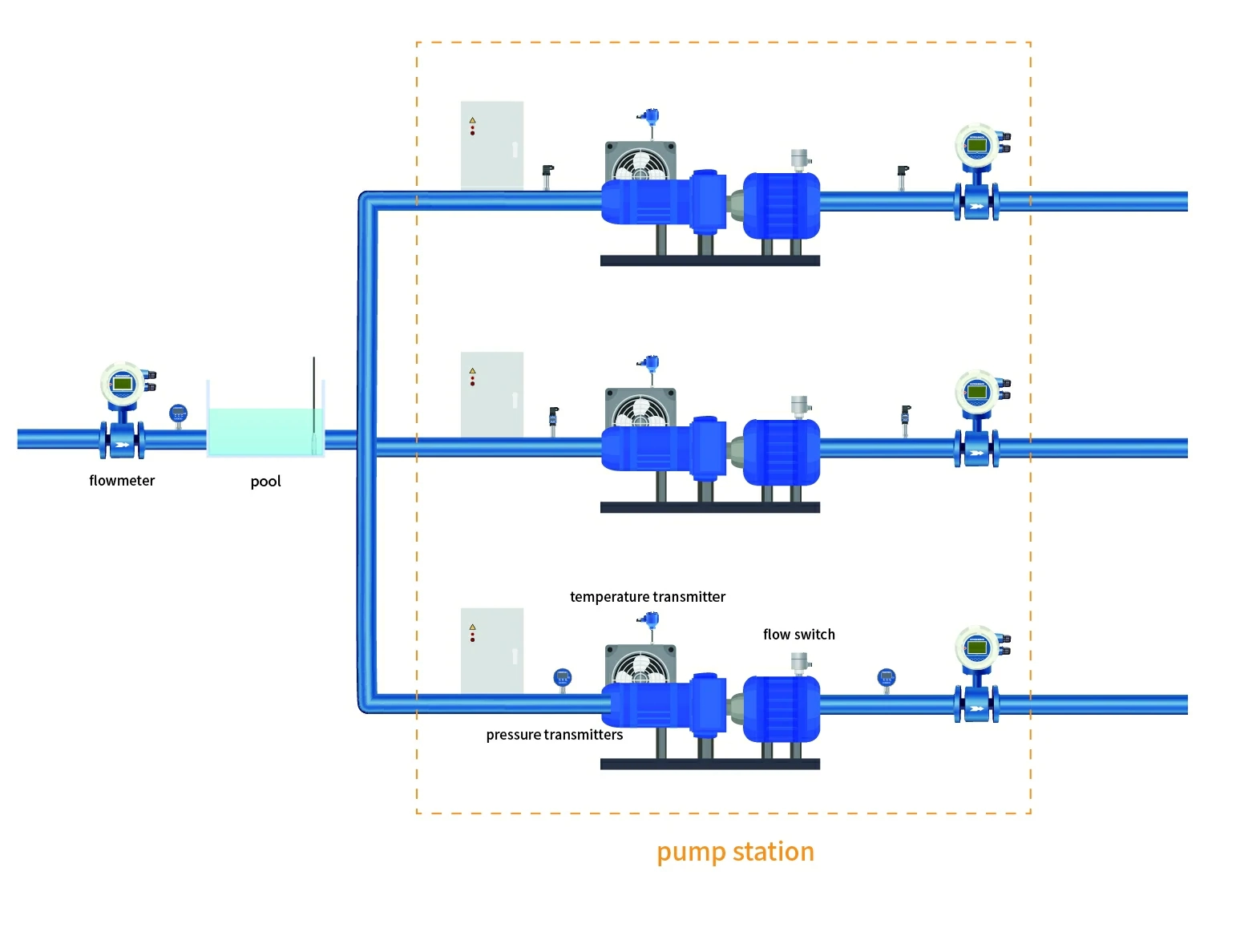

Irrigation and drainage pumping stations solve the problem of gravitational water diversion in irrigation areas, enabling cross-basin water transfer. MicroSensor provides real-time pressure and flow monitoring for inlet and outlet pipelines of these pumping stations, contributing to the accurate measurement of information-based irrigation areas and high-standard farmland construction.

more info...

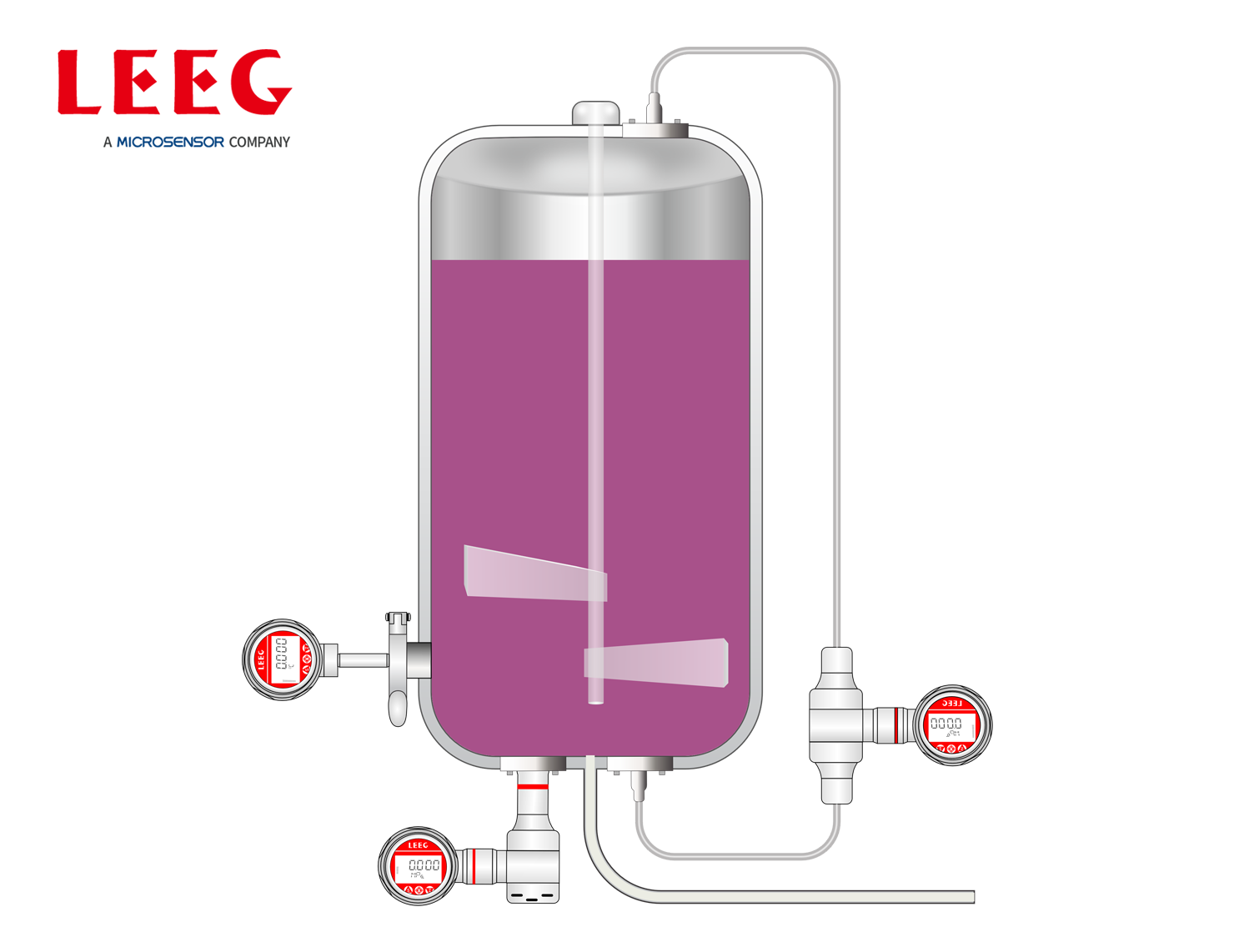

In beverage storage tanks, the role of the liquid level transmitter is to monitor the material inventory in real time by measuring the liquid level height of milk or beverages in the tank; the temperature transmitter measures the temperature of the material in the tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration due to excessively high temperature or affecting the taste of the product due to excessively low temperature.

more info...