Recently, MICROSENSOR's developed and manufactured MDM7000 series smart pressure transmitters have successfully obtained the three major international explosion-proof certifications, namely the ATEX by the CSA Group, the CSA C-US, and the IECEx. The successful acquisition of these three explosion-proof certifications marks that the MDM7000 series smart pressure transmitters meet the strict performance requirements of environmentally safe areas and have reached the world's advanced level.

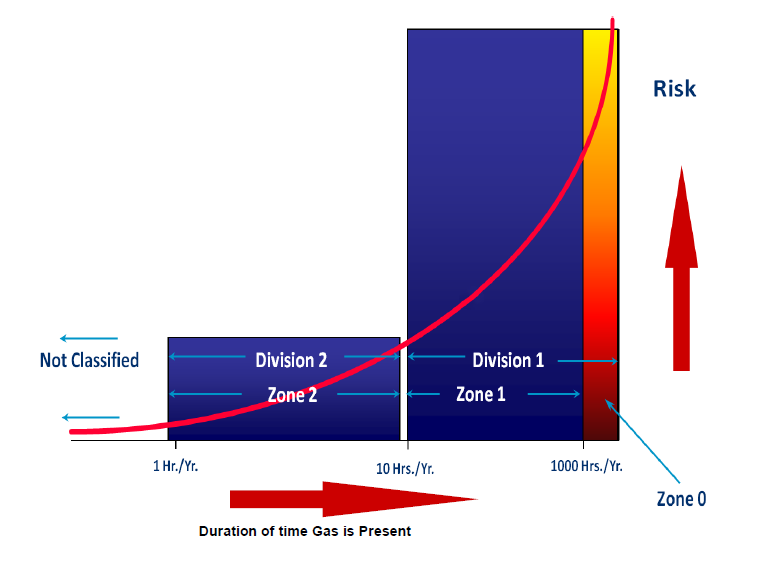

In the field of explosion-proof technology, the three major certifications are based on two explosion-proof systems. The Division system is the most widely used explosion-proof system in the North American market, and Division 1 is the highest level in the system. In addition, the IEC Zone system is another system suitable for the global market. Zone 0 is the highest level in the IEC Zone system.

| IEC Zone System | North American Division System | Hazardous Areas |

| Zone 0/Zone 20 | Division 1 | Areas where explosive environments (gas or steam) exist continuously, intermittently or periodically during normal operation. |

| Zone 1/Zone 21 | ||

| Zone 2/Zone 22 | Division 2 | During normal operation, explosive atmosphere (gas or steam) will not appear, and if it does, it will only exist for a short period of time. |

The higher the risk of explosion, the higher the requirements for the equipment

ATEX certificate

The ATEX certificate is a mandatory requirement of EU Directive 2014/34/EU. It is specially designed for equipment used in hazardous areas to ensure its safety and compliance. ATEX is undoubtedly the authoritative standard in the field of explosion-proof worldwide, especially widely recognized in the oil, gas and chemical industries. Equipment must undergo rigorous design, production and quality management assessments to ensure safety and reliability in explosive atmospheres in order to obtain an ATEX certificate. In addition, ATEX is a mandatory requirement for entering the EU market and is the basis for obtaining other global explosion protection certificates.

IECEx certificate

IECEx certificates are the international benchmark for explosion-proof equipment safety certification, especially outside the EU. Manufacturers can easily enter the global market with IECEx certificates, without having to apply for multiple country-specific certificates. Compared with the EU's mandatory ATEX standard, IECEx has a higher global recognition and is suitable for a variety of explosion-proof environments. As global safety standards continue to improve, IECEx certificates will become the mainstream safety standard in the international market in the future.

CSA C-US certificate

The CSA C-US certificate is mandatory in Canada and is widely recognized in North America and internationally, especially in the oil and gas industry, where it is considered an important standard for ensuring the safe use of equipment in high-risk areas. In the United States, many states consider CSA certification to be as important as UL certification, allowing CSA-certified products to enter the Canadian and U.S. markets. The entire CSA certification process is transparent and rigorous to ensure that certified products meet the highest safety and quality standards.

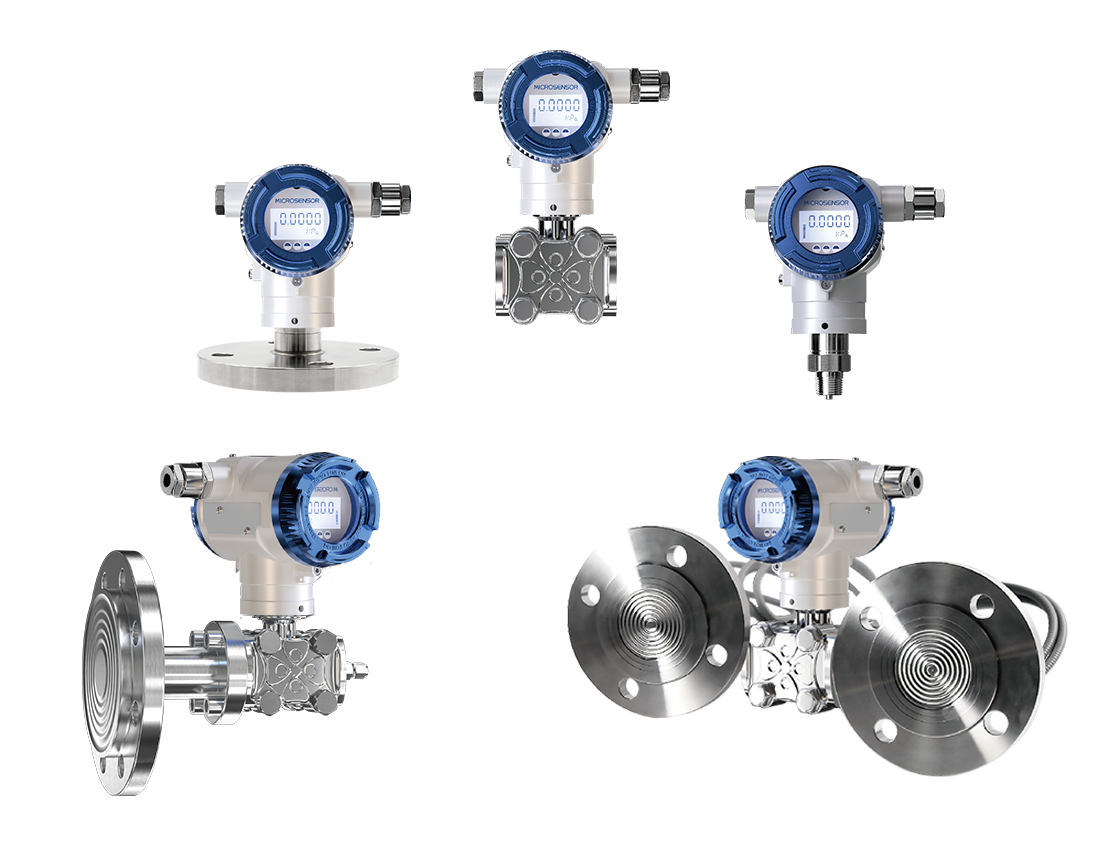

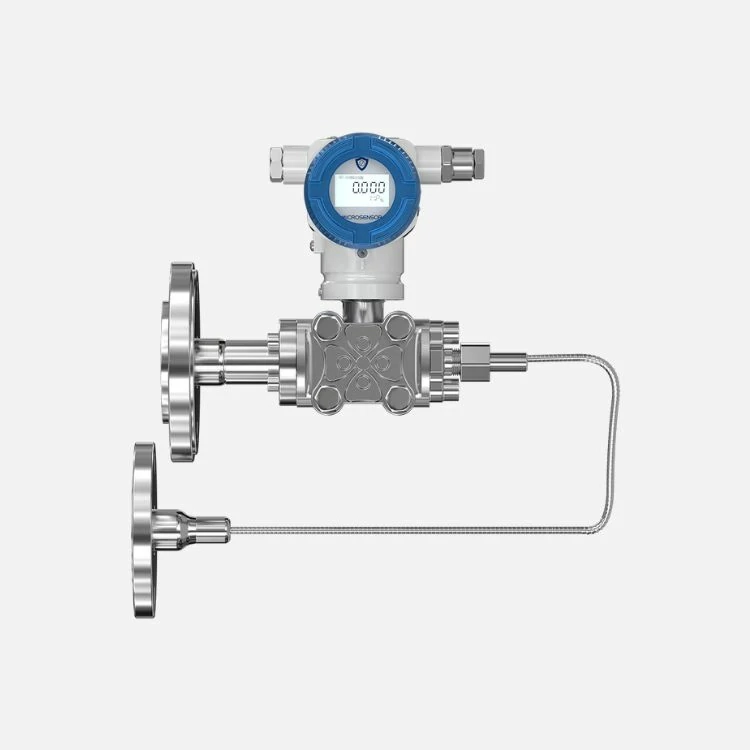

MICROSENSOR MDM7000 Series Smart Pressure Transmitters

Obtaining the three major explosion-proof certificates is no easy feat. First, a comprehensive risk assessment of the product is required to ensure operational safety in explosive atmospheres. Next, the product must undergo rigorous testing and evaluation, including high-temperature resistance, corrosion resistance, pressure resistance testing, as well as dust-proof and gas explosion-proof performance testing. Finally, detailed technical documentation must be prepared, and independent third-party certification bodies must review and test to ensure that all aspects of design, materials, manufacturing processes, etc., meet the highest safety standards.

In an increasingly competitive environment, MICRO SENSOR CO., LTD. has been exploring the international market, adhering to the concept of innovative research and development, constantly upgrading product system standards, improving production efficiency, improving employees' working conditions, and satisfying customers. This demonstrates our corporate vision of Sensing Tomorrow with Reliable Measurement and Control Solutions.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD