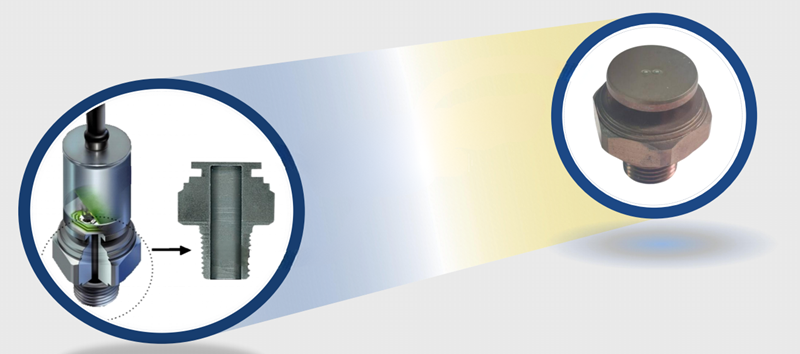

What's the Micro-Fused Silicon Strain Gauge Technology?

Micro-fused silicon strain gauge technology (MSG) is also called micro-fused technology or glass micro-melting technology. It uses high-temperature glass powder as the packaging medium to combine the silicon strain gauge and the stainless steel diaphragm into one structure through high-temperature sintering. This technology can realize the conversion from pressure to electrical quantity output.

Micro-Fused Pressure Transmitter Advantages

• Wide Measure Range: 10bar~3000bar; the diaphragm with stainless steel material can withstand greater pressure.

• High Overload: the integral diaphragm can withstand 2~5 times overload and up to 10 times burst pressure; instantaneous pressure shock can be effectively resisted.

• Complex Environment Use: wide temperature range -40℃~125℃; anti-vibration, impact resistance.

• No Leakage: no silicone oil filling, no leakage and pollution risk.

Micro-Fused Pressure Transmitter Applications

• Hydraulic Servo Control System Pressure Monitoring

A hydraulic servo control system uses hydraulic technology to control mechanical movement. Controlling and adjusting hydraulic oil by micro-fused pressure transmitters can achieve efficient operation under various working conditions.

When hydraulic cylinders or motors are operating, stable pressure control can improve response speed and ensure the accuracy of action. In the case of load changes, real-time feedback and control of pressure value can quickly adapt to load changes and keep the system in the best working state.

• Aerial Work Platform Pressure Monitoring

Pressure transmitters are installed on hydraulic cylinders, lifting cylinders, or valve blocks. The control system optimizes lifting and tilting angles based on the pressure data provided by the transmitter. Additional pressure switches provide the functions of alarm and pressure relief.

To improve safety, the dual output type of MPM4511A pressure transmitter provides redundant signals. If one output signal fails (for example, sensor damage or circuit problems), the other signal can still work. This redundant signal design improves system reliability and safety, which is especially important in high-risk aerial work environments.

• Plastic Molding Pressure Monitoring

The injection molding equipment needs to measure the pressure inside the mold cavity during the plastic injection molding process.

Our pressure transmitters provide crucial data to optimize molding parameters and ensure consistent quality of the final molded part. The pressure sensors also identify potential issues like uneven filling, short shots, or overfills, ultimately reducing scrap and improving production efficiency.

• Coffee Machine Pressure Monitoring

Monitoring the pressure in a coffee machine, especially for espresso machines, is crucial for ensuring optimal extraction and overall performance. MPM4503 pressure transmitter controls the pressure value, which helps maintain consistency in brewing. It is essential for quality control, especially in commercial coffee machines.

Recommended Silicon Micro-fused Pressure Transmitter

| MPM4511 | MPM4503 | MPM4511A | MPM4511H |

|  |  |  |

1. High reliability 2. Wide operating temperature range 3. Vibration and shock resistance 4. Wide application range | 1. Cost-effective 2. Compact structure 3. High performance with low cost | 1. Single or dual output optional 2. PLd certificated 3. High voltage & overload resistance 4. Quick response time | 1. Special for hydrogen 2. Corrosion-resistant 3. Explosion-proof certificated |

| Hydraulic and pneumatic system; Aerial work platform (AWPs), scissor lift, etc. | Hydrogen Measurement | ||

MicroSensor also provides customized micro-fused pressure sensor or pressure transmitter solutions to meet unique demands. Whether it's for specialized pressure ranges, materials, or specific working conditions, our technical team is equipped to deliver custom pressure sensors aligned with your project needs.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD