High Temperature Pressure Transmitter

Range: 0.1Bar~1000Bar

4~20mA DC

Media temp.: -40℃~150℃ or Customized

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4503

Used For

VF Constant Pressure Water Supply, Compressor, Energy & Water Treatment System, Building Automation System

Leave a MessageMPM4503 Pressure Transmitter is a cost-effective product using micro-fused technology. The micro-fused technology greatly improves the accuracy and stability of the compact pressure transmitter. Vibration and shock indicators meet pressure measurement and control under various environmental conditions. The stainless steel sensing elastomeric diaphragm is resistant to transient overload pressure problems. MPM4503 can support a variety of output signals. The miniaturization of product structure is more suitable for use in space-constrained or size-constrained environments. Batch compensation, calibration, and testing of the MicroSensor production line ensure production efficiency. The process is mature and the pressure transducer can be customized according to customer requirements.

Feature

• High precision meets precise control and monitoring needs

• Micro-fused Technology Pressure Transmitters

• High temperature resistance, shock resistance

• Strong overload capacity

Image:

MPM4503 Pressure Transmitter is a cost-effective product using micro-fused technology. The micro-fused technology greatly improves the accuracy and stability of the compact pressure transmitter. Vibration and shock indicators meet pressure measurement and control under various environmental conditions. The stainless steel sensing elastomeric diaphragm is resistant to transient overload pressure problems. MPM4503 can support a variety of output signals. The miniaturization of product structure is more suitable for use in space-constrained or size-constrained environments. Batch compensation, calibration, and testing of the MicroSensor production line ensure production efficiency. The process is mature and the pressure transducer can be customized according to customer requirements.

Feature

• High precision meets precise control and monitoring needs

• Micro-fused Technology Pressure Transmitters

• High temperature resistance, shock resistance

• Strong overload capacity

Range: 0.1Bar~1000Bar

4~20mA DC

Media temp.: -40℃~150℃ or Customized

Heavy Duty & Shock Resistance

16Bar~1000Bar

Accuracy:±1%FS

Applicable for Hydraulic and Pneumatic

0bar~16bar …350bar

Accuracy:±0.5%FS

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

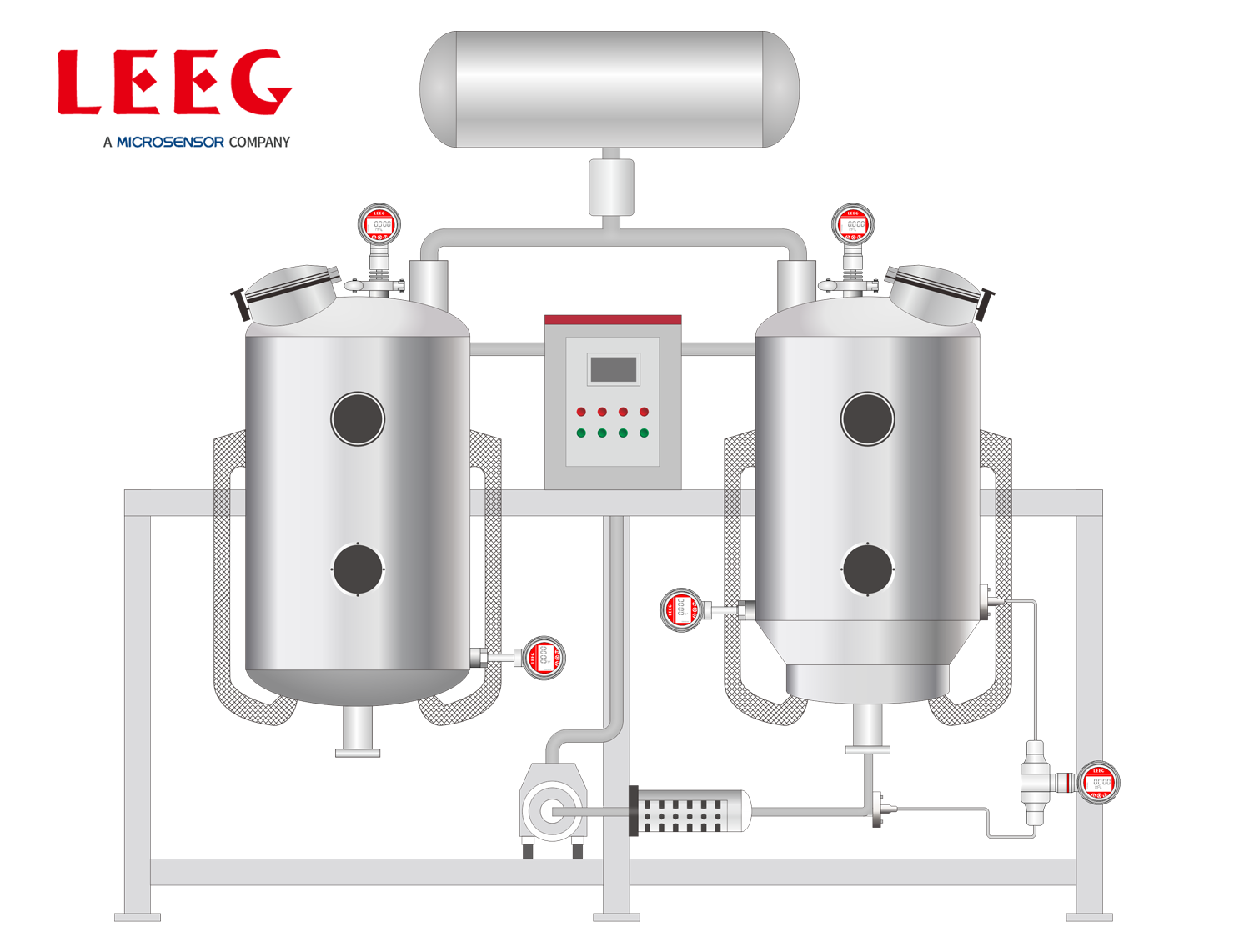

The production of different paste-like drugs uses a concentration process when processing raw materials. The evaporator features high temperature and vacuum. After the concentration process, it needs to be cleaned with efficient and strong chemical detergents. The pressure, temperature and level transmitters in the evaporator effectively ensure the normal and efficient operation of the concentration and washing process.

more info...

To ensure the fuel supply of the main engine, the separated heavy oil is first pumped to the settling tank, where the oil is heated and separated in the heating coil, and then purified by the oil separator before entering the daily tank through high-level overflow. The daily tank is directly connected to the main engine, boiler or other equipment, and the oil can be heated and used at any time.

more info...

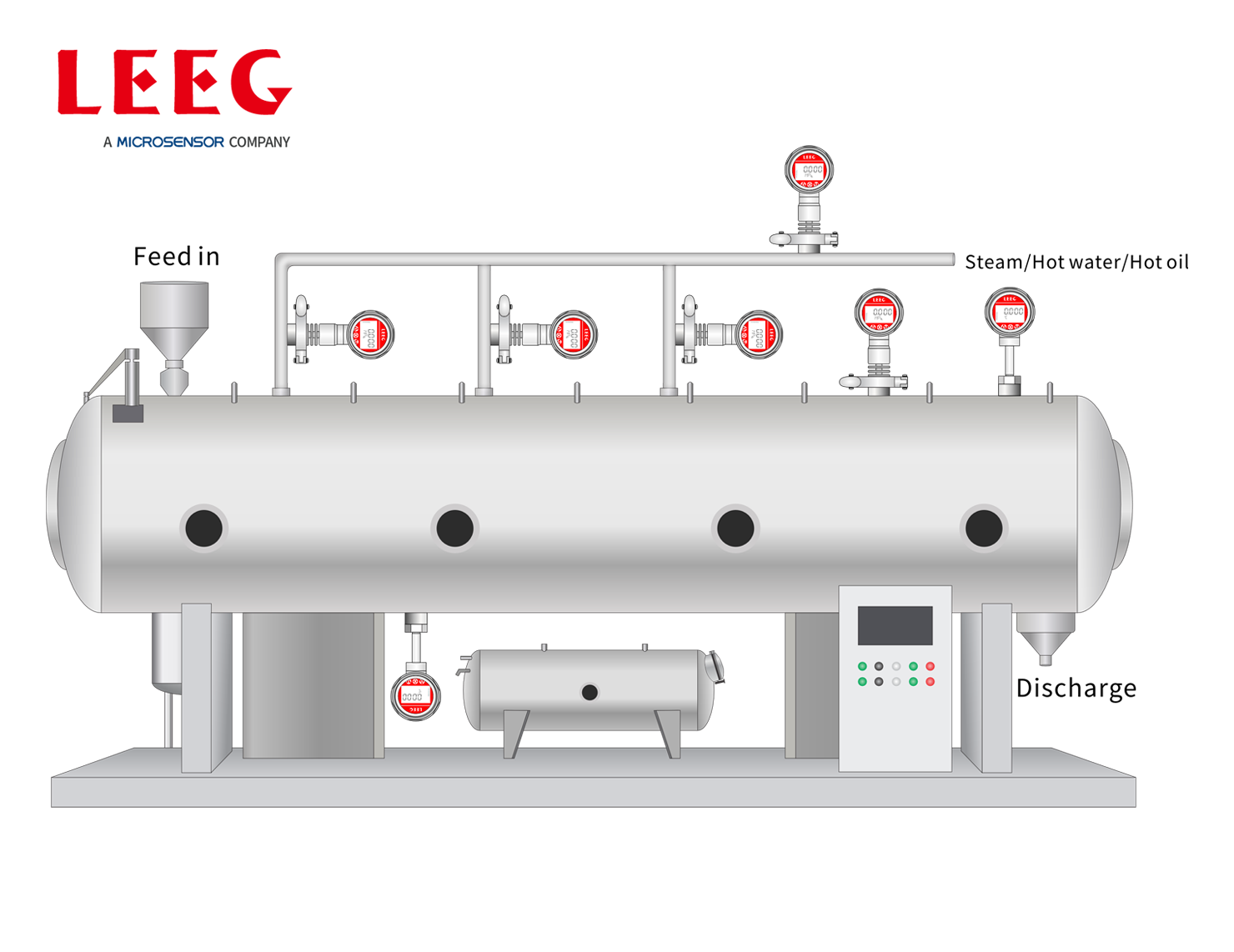

Dryers are often used to dry medicines or extract active ingredients from traditional Chinese medicines, which are easily decomposed in high temperature environments. Temperature measurement is required in the heating area, cooling area and material outlet of the dryer, and pressure transmitters are used to measure the pressure of air or gas to help adjust the air flow speed and fan operation status, or measure the pressure of steam, hot water, and hot oil pipelines.

more info...

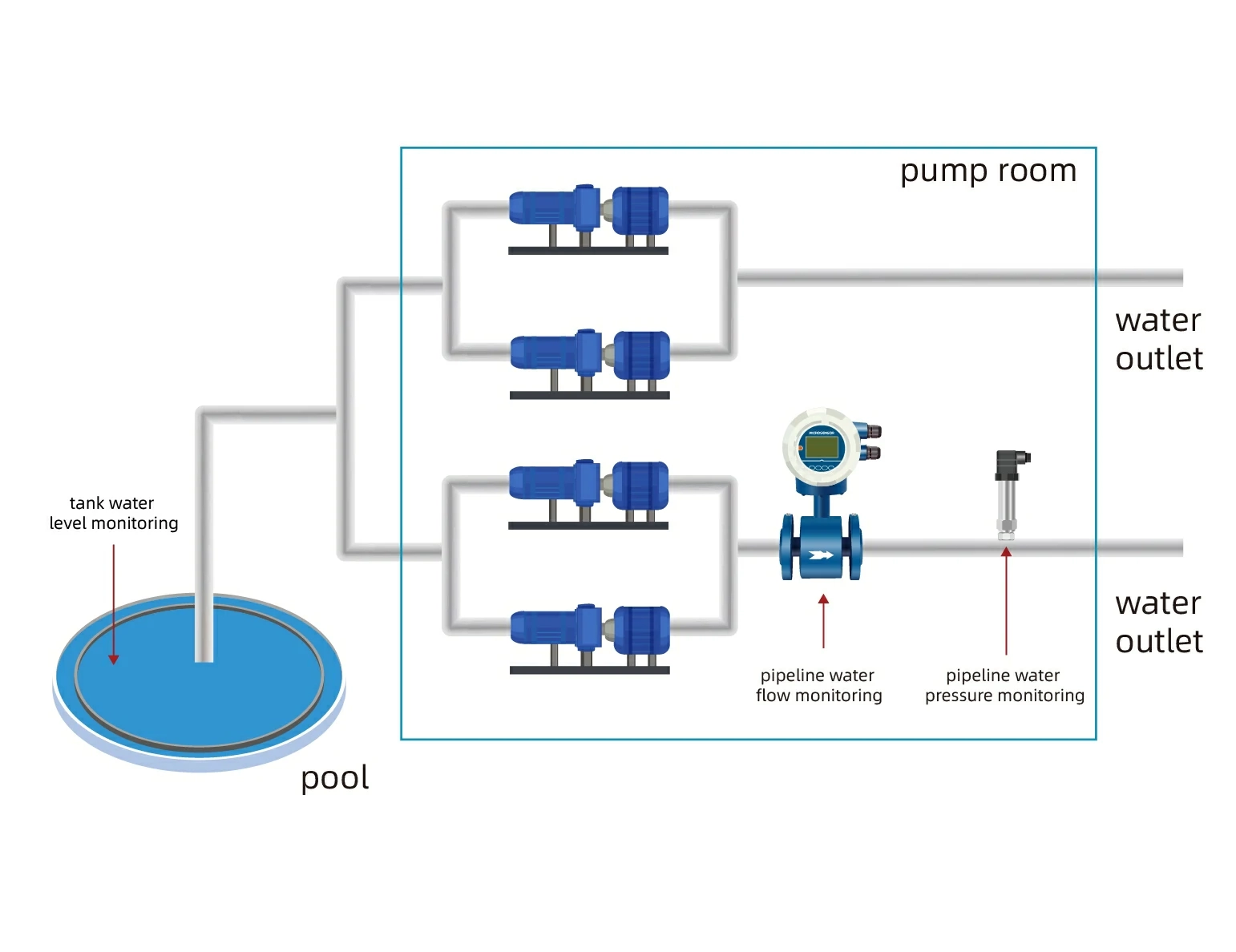

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...