Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

MPM458GUHP

Used For

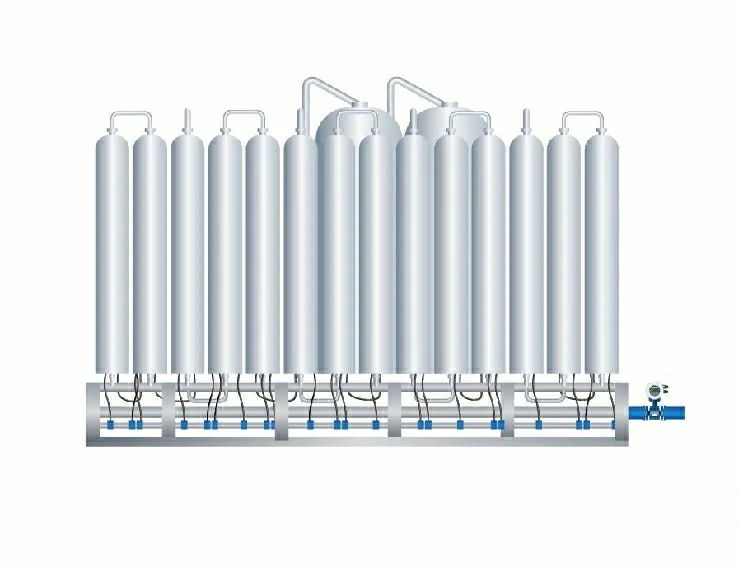

Semiconductor, Solar Photovoltaic, Flat Panel Display, High-purity Media and Special Gas Systems

Leave a MessageMPM458GUHP is a dedicated pressure transmitter with a precise product design, fully digital temperature compensation and calibration, excellent EMC rating, and a zero-adjustment knob, ensuring the accuracy and stability of the measurements. The full welded structure, VCR process connection method, and carefully selected construction materials provide strong sealing and corrosion resistance.

Manufactured and processed in a Class 100 cleanroom, the wetted parts are electropolished and cleaned, and the product has passed international certification, making it suitable for various pressure monitoring and measurement applications in the semiconductor industry involving high-purity media.

Specifications

• Electrical connection: Circular aviation connector M12×1 (4pin) IEC 61076-2-101

• Process connection: 9/16-18UNF-2A

• Construction feature: Fully welded

• Measuring medium: High-purity media and special gas systems

Image:

MPM458GUHP is a dedicated pressure transmitter with a precise product design, fully digital temperature compensation and calibration, excellent EMC rating, and a zero-adjustment knob, ensuring the accuracy and stability of the measurements. The full welded structure, VCR process connection method, and carefully selected construction materials provide strong sealing and corrosion resistance.

Manufactured and processed in a Class 100 cleanroom, the wetted parts are electropolished and cleaned, and the product has passed international certification, making it suitable for various pressure monitoring and measurement applications in the semiconductor industry involving high-purity media.

Specifications

• Electrical connection: Circular aviation connector M12×1 (4pin) IEC 61076-2-101

• Process connection: 9/16-18UNF-2A

• Construction feature: Fully welded

• Measuring medium: High-purity media and special gas systems

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

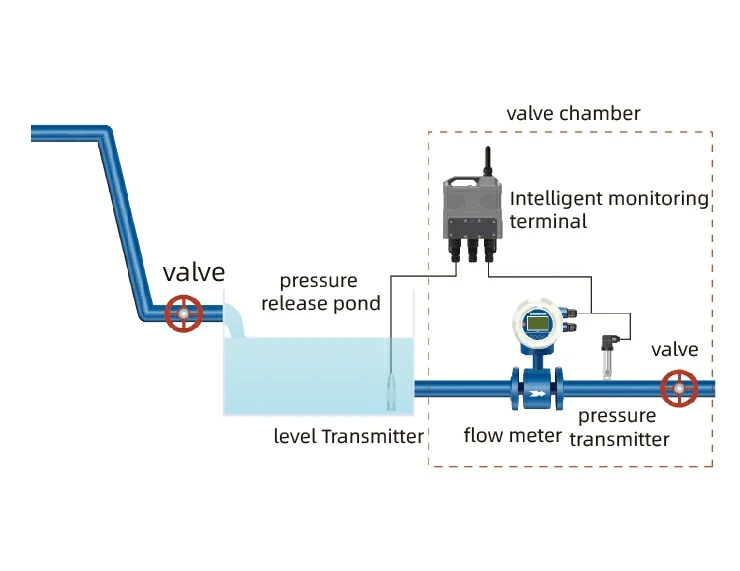

The pressure-release pond can regulate the pressure of the water supply network. It adjusts the pipe network pressure by increasing or decreasing the water volume. The pond maintains the pipelines at a normal level. At various stages of the pressure-release pond, different instruments need to be installed.

more info...

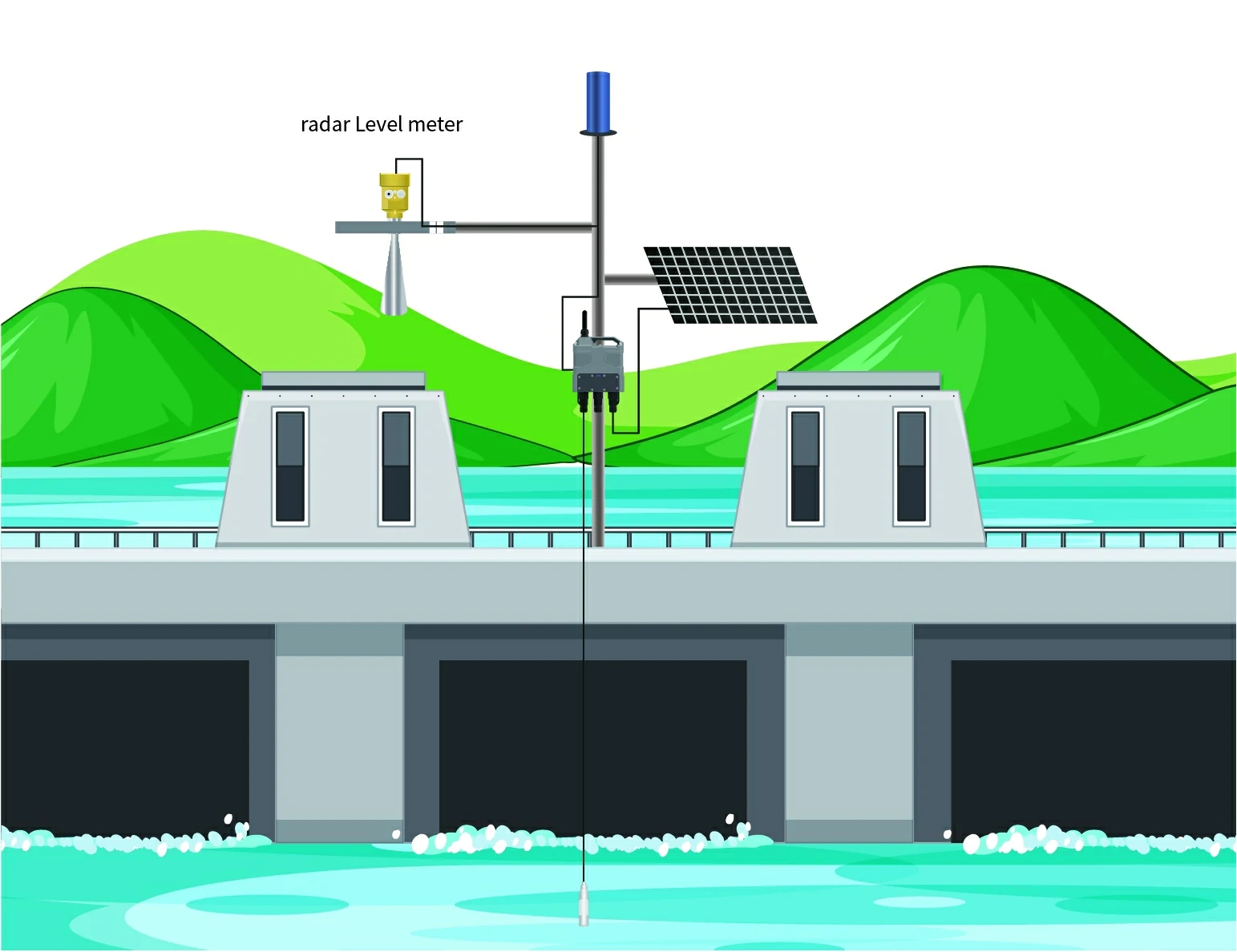

Real-time collection of reservoir water level, rainfall, and other information at dam monitoring points. Based on the changes in water level and the maximum capacity of the dam, calculations are made, and warnings and alarms are issued when the water level rises above the alert value.

more info...

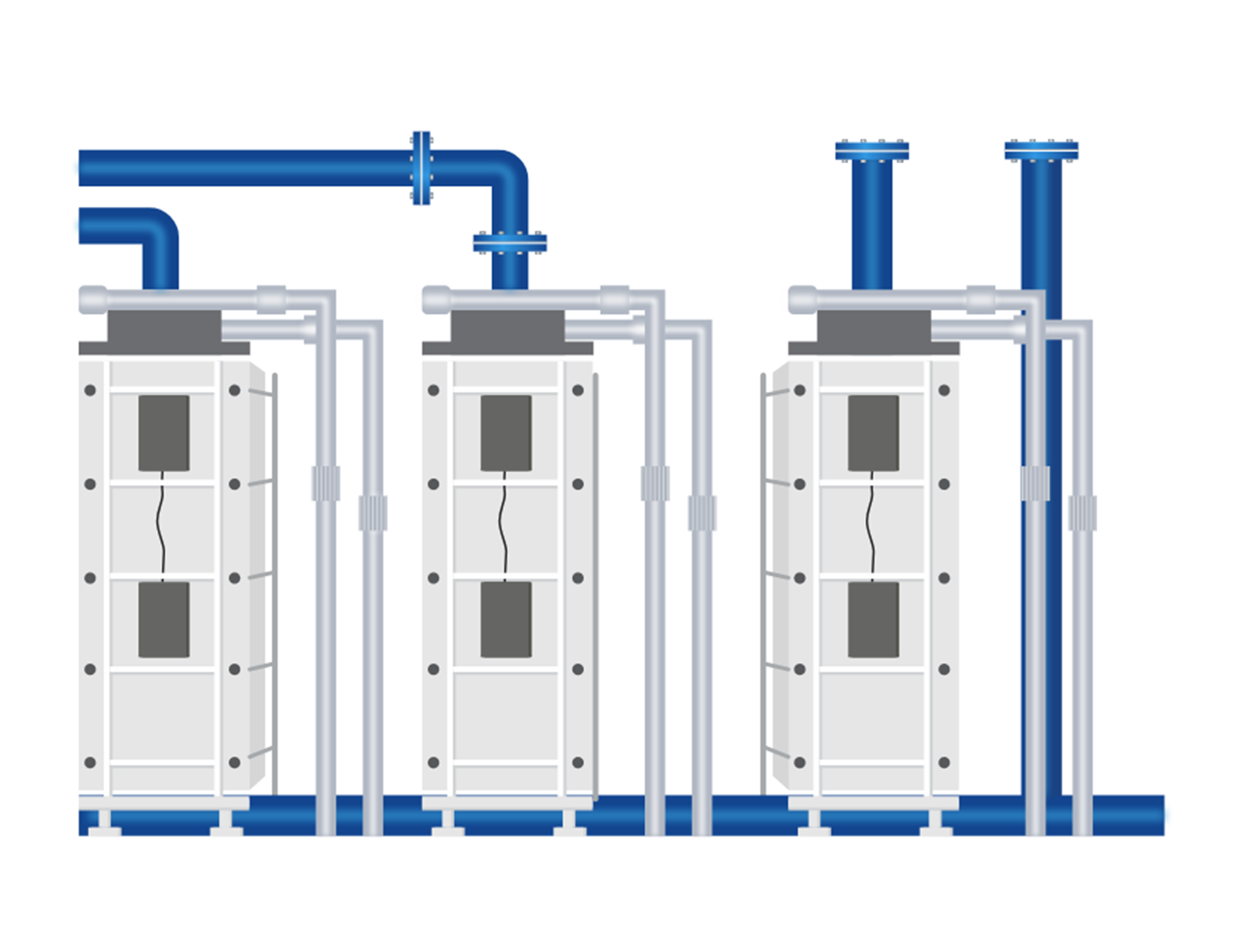

In the paper industry, the alkali recovery system is an essential part that operates under harsh conditions. The system needs strong pressure, temperature, and flow instrumentation to handle high temperatures, high pressures, and corrosive media.

more info...

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

more info...