Application Introduction

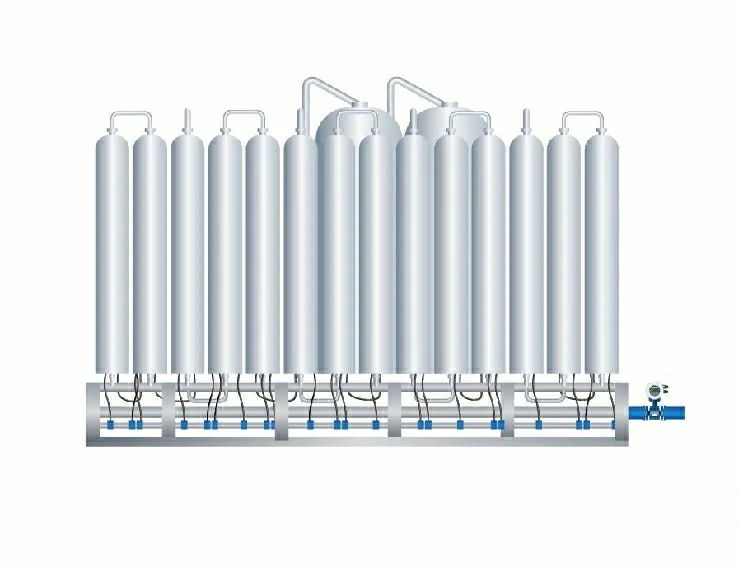

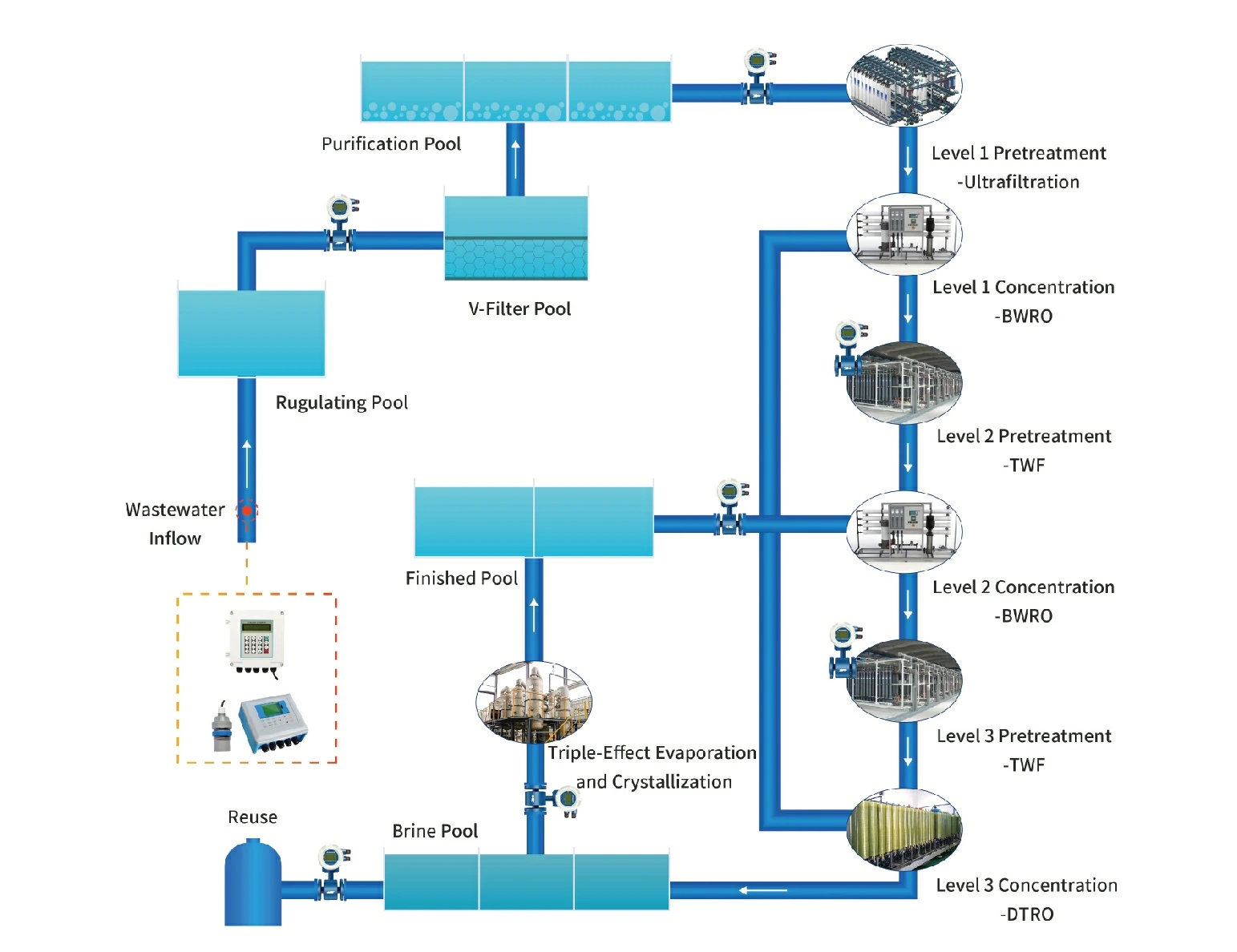

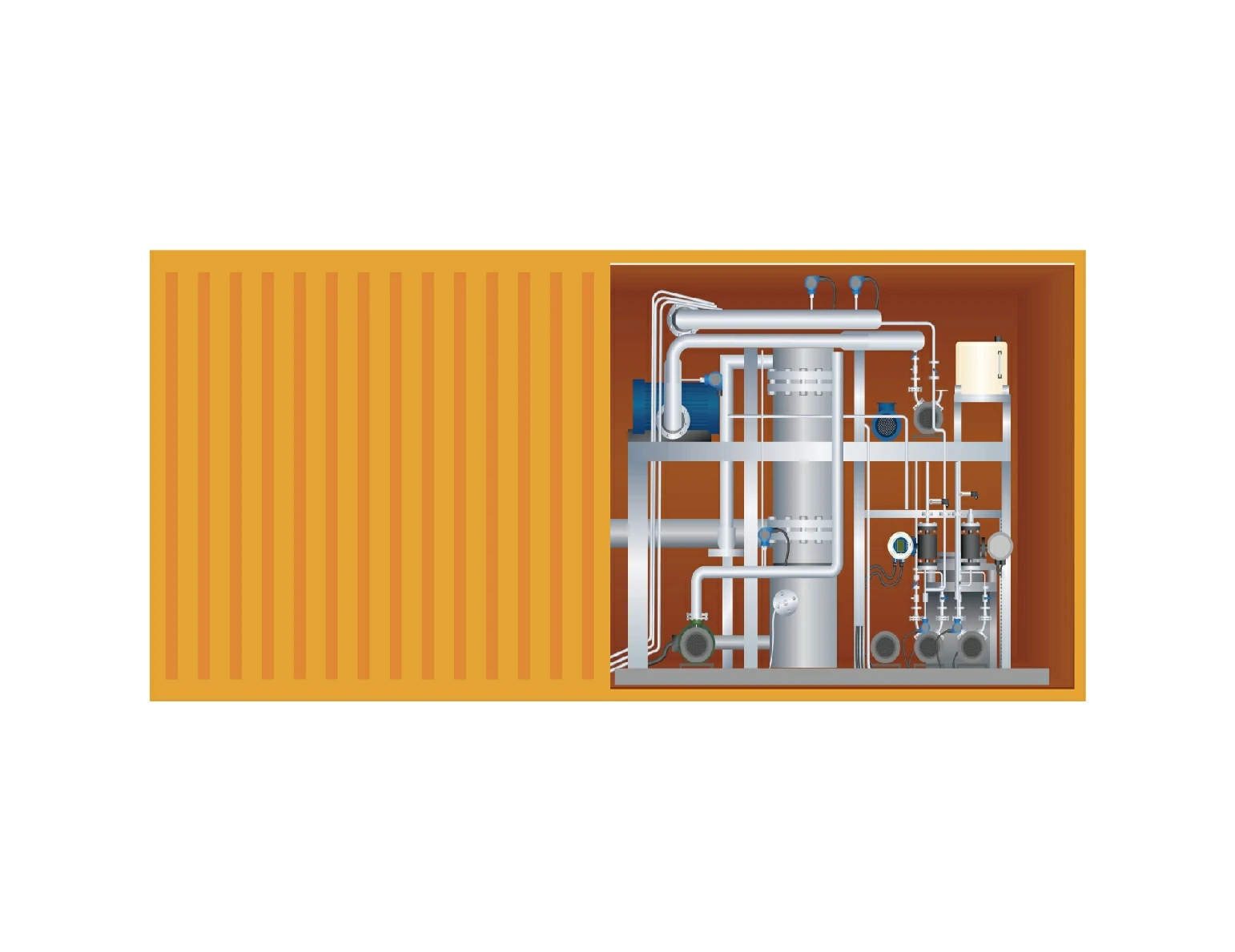

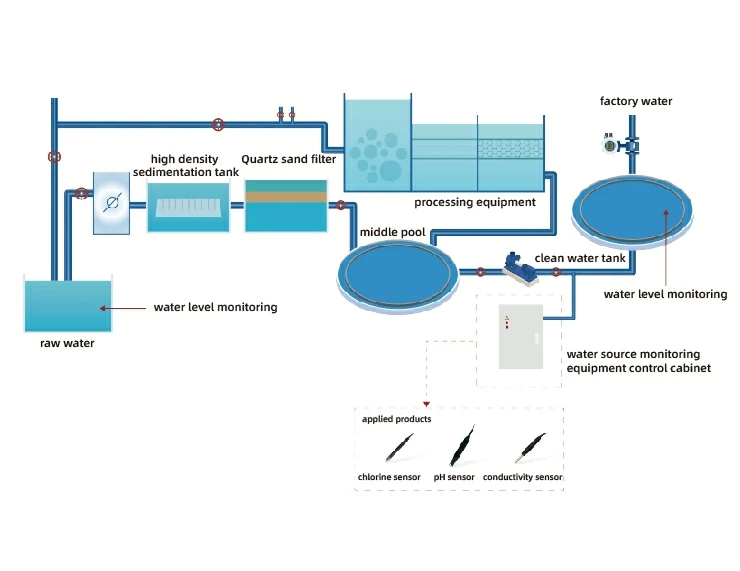

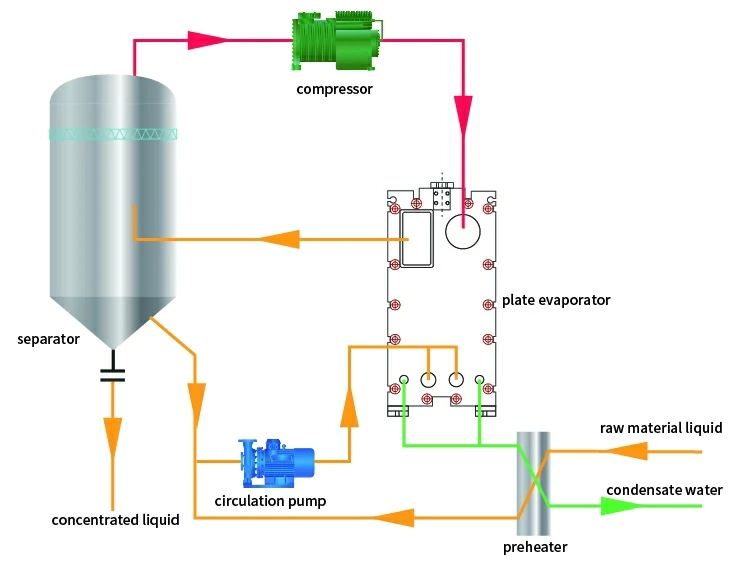

The current comprehensive solution for vadose solution is to adopt vadose solution and membrane concentrated liquid treatment technology, as well as integrated treatment technology for high-risk special wastewater. Monitoring instruments are installed on the treatment equipment to ensure the vadose solution treatment process meets the emission standards, and the data is transmitted to the central platform of the regulatory department.

Contact Engineer

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD