Hemodialysis is a common treatment therapy, including in-center and home hemodialysis. Among them, the dialysis machine is a very important equipment. It consists of two parts: the blood monitoring alarm system and the dialysate supply system.

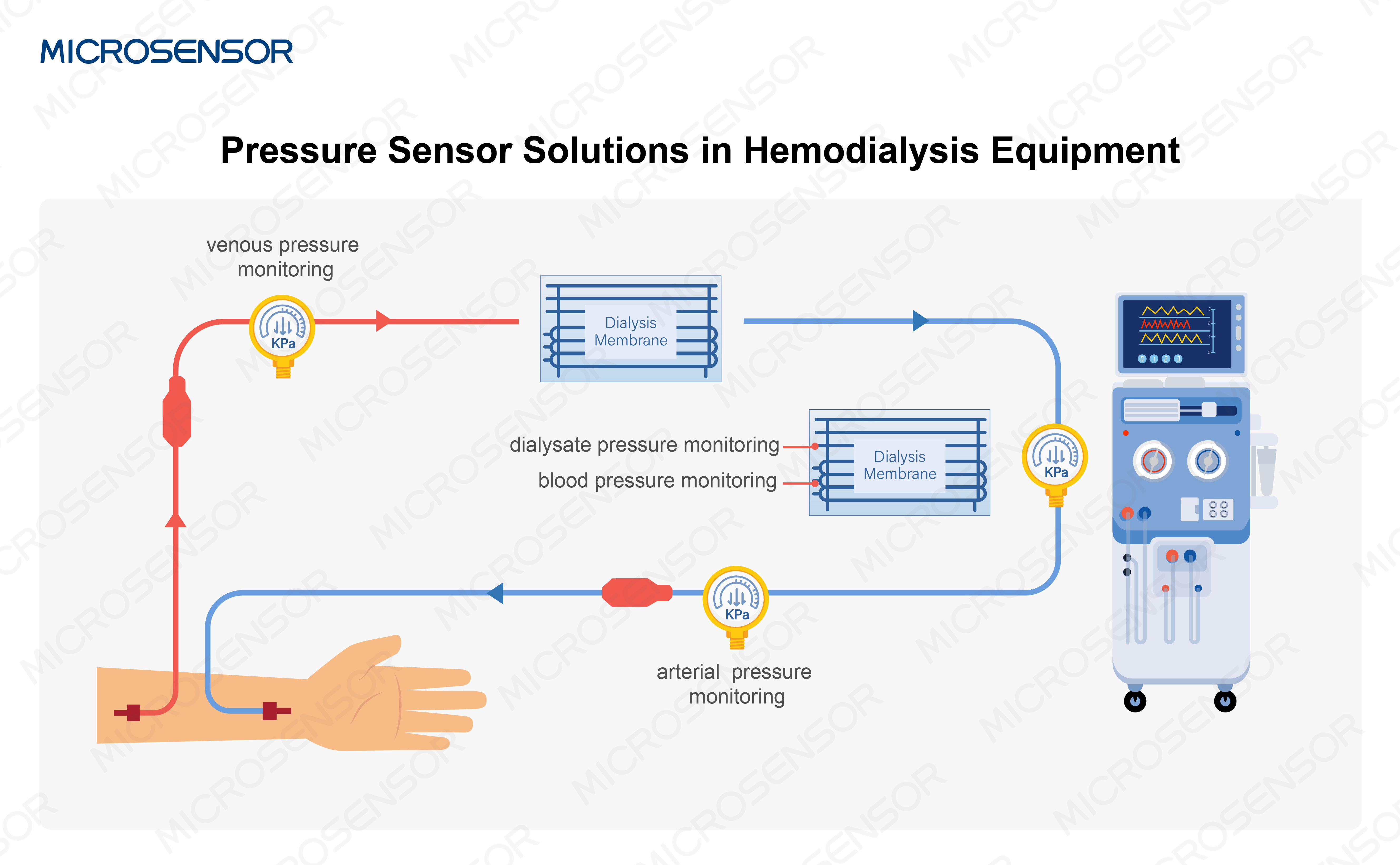

The blood monitoring alarm system includes a blood pump, a heparin pump, arteriovenous pressure monitoring and air monitoring, etc. The dialysate supply system includes temperature control, a liquid preparation system, a degassing system, a conductivity monitoring system, ultrafiltration monitoring and blood leakage monitoring, etc.

How does the Hemodialysis Work?

The dialysis concentrate and dialysis water are prepared into qualified dialysis fluid through the dialysis fluid supply system, and then pass through the hemodialyzer to undergo solute diffusion, osmosis, and ultrafiltration with the patient's blood drawn out from the blood monitoring alarm system. After the action, the patient's blood returns to the patient's body through the blood monitoring alarm system, and at the same time, the liquid used for dialysis is discharged from the dialysis fluid supply system as waste liquid. It is circulated back and forth continuously to complete the entire dialysis process.

Importance of Pressure Sensors in Hemodialysis Equipment

Accurate measurement of dialysate, arterial and venous pressure is essential for patient safety during dialysis treatment. when selecting pressure sensors for dialysis machines, it’s imperative to prioritize safety, precision, and material quality to ensure effective patient care and trust in the treatment process.

Pressure sensors need to accurately detect fluid and blood flow pressure to ensure that the pressure is maintained within the applicable range to avoid overpressure or underpressure, which affects the effectiveness of treatment. Because both overpressure and underpressure can cause blood vessel rupture or bubbles in the pipeline, which can be harmful to the patient's health. The materials used in these pressure sensors are essential, they must be biocompatible to ensure patient safety and prevent any adverse reactions. In addition, pressure sensors should provide a variety of installation and sealing methods to adapt to different application locations.

Micro Sensor Pressure Sensor Solutions for Hemodialysis Equipment

Model: MPM3801. MPM288SA. MPM288DI. MPM281VC

Pressure range:-1Bar3.5Bar, -1Bar10Bar, etc.

Output signal: mV, 4-20mA,0.5-2.5V, 0.5-4.5V, 1IC

Pressure connection: 0-ring sealed, 1/4" G, 1/4" NPT and other threads available

|  |  |  |

| MPM3801 | MPM288SA | MPM288DI | MPM281VC |

Benefit

● Electrical connection: wires, ribbon wires with JST or customized connector

● Customized structure to fit in the printer design

● No calibration and configuration are required.

● Compact size and fully Titanium or SS316 material used

● Excellent long-term stability

Micro Sensor offers a series of pressure sensors suitable for pressure measurement in hemodialysis equipment with custom design solutions. The pressure sensor with optional SS3L6L and Titanium housing is compatible with the patient and the dialysate liquid, with no harm to the human body. With a professional R&D team, tailored designs are available such as installation, sealing, sizes, etc.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD